Treatment equipment for waste gas

A waste gas treatment device and waste gas treatment technology are applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., which can solve the problems of no cooling device, no timely adjustment, equipment burning and fire, etc., and achieve risk avoidance and good fire prevention treatment device, avoiding the effect of polluting the air environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

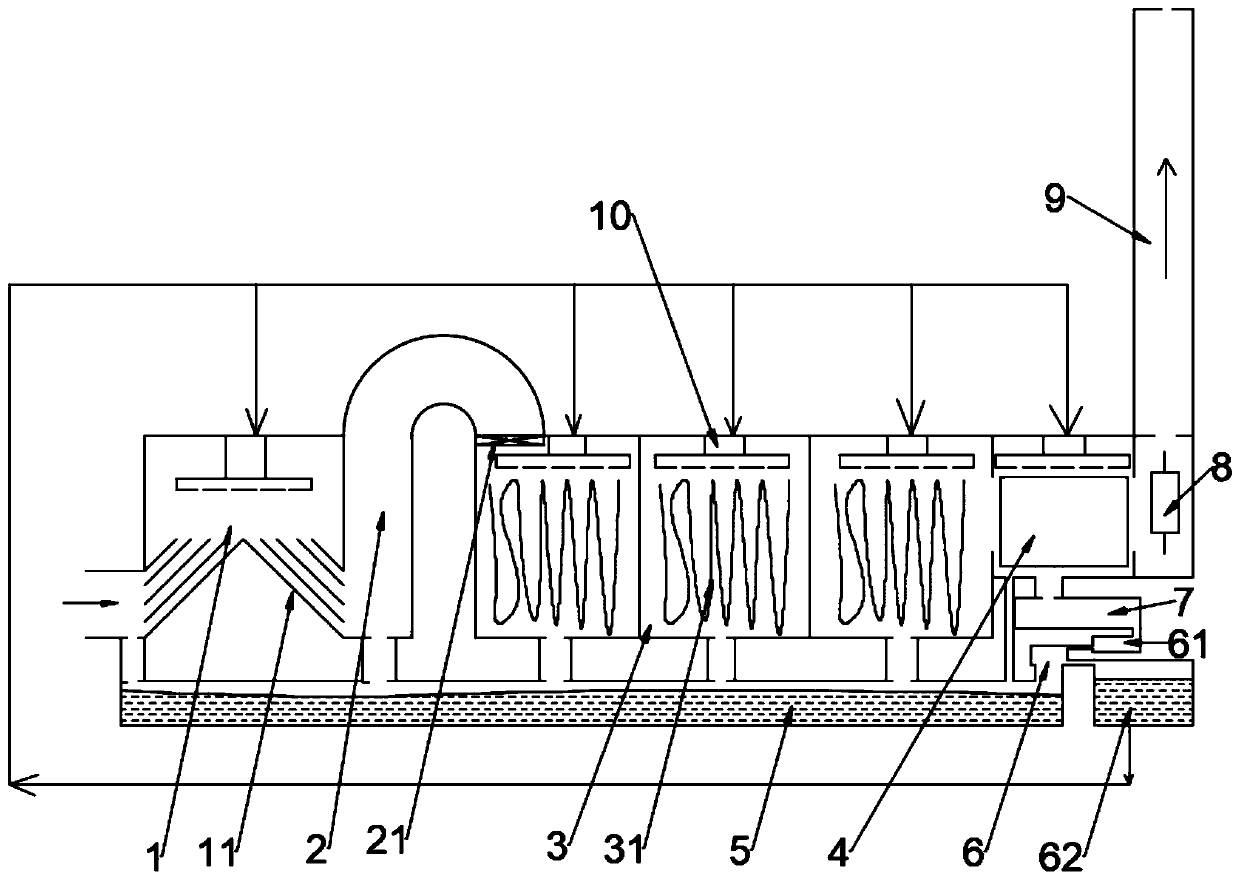

[0047] This embodiment provides an exhaust gas treatment device, such as figure 1 shown, including:

[0048] Washing room 1, said washing room 1 is provided with shutters 11 which form a certain angle with the horizontal plane;

[0049] A fireproof pipe 2 is connected to the washing chamber 1 and the waste gas treatment chamber 3, and a fireproof valve 21 is arranged in the fireproof pipe 2;

[0050] The exhaust gas treatment chamber 3 is provided with a filter cotton 31 for absorbing dust in the exhaust gas, and the exhaust gas treatment chamber 3 is provided with a temperature sensor;

[0051] The activated carbon adsorption chamber 4 communicates with the exhaust gas treatment chamber 3, and has several rows of activated carbon inside;

[0052] The drainage channel 5 is arranged below the washing chamber 1, the waste gas treatment chamber 3 and the activated carbon adsorption chamber 4, and communicates with the water washing chamber 1, the waste gas treatment chamber 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com