Boiler tool special for oil cooler

An oil cooler and furnace technology, which is applied in the field of supporting tooling for automobile radiators, can solve the problems of parts dislocation, transmission chain adhesion, tape loss, etc., and achieve the effect of eliminating parts dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

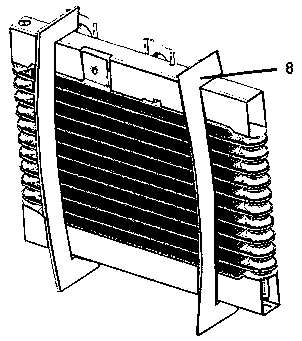

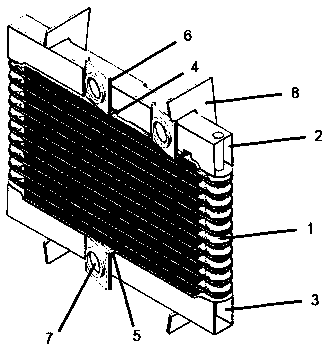

[0019] This embodiment: as figure 1 , 2 As shown, a special furnace tooling for oil cooler, including oil cooler main body 1, the top end of the oil cooler main body 1 is clipped to the upper furnace pad 2, and the bottom end is clipped to the furnace lower pad 3, so that The upper groove 4 of the furnace upper pad 2 avoids the upper bracket 6, the lower groove 5 of the furnace lower pad 3 avoids the lower bracket 7, and the furnace upper pad 2 and the furnace lower Pad strip 3 is fastened through clamp 8 inner edge.

[0020] The furnace upper pad 2, the furnace lower pad 3 and the fixture 8 are made of stainless steel.

[0021] The clamp 8 contacts the brazing furnace chain downwards when passing through the furnace.

[0022] The four corners of the furnace upper pad 2 protrude and have 45° slopes to press against the two ends of the main body 1 of the oil cooler.

[0023] working principle:

[0024] In this patent, the top of the main body of the oil cooler is clamped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com