Coordinate algorithm of MARK points on printed board in high-precision printing machine based on machine vision

A machine vision, high-precision technology, applied in printing, instruments, computing, etc., can solve the problems of insufficient light and lighting environment, low accuracy of positioning process, waste of time, etc., to improve the efficiency of equipment adjustment, reduce requirements, and improve convenience sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

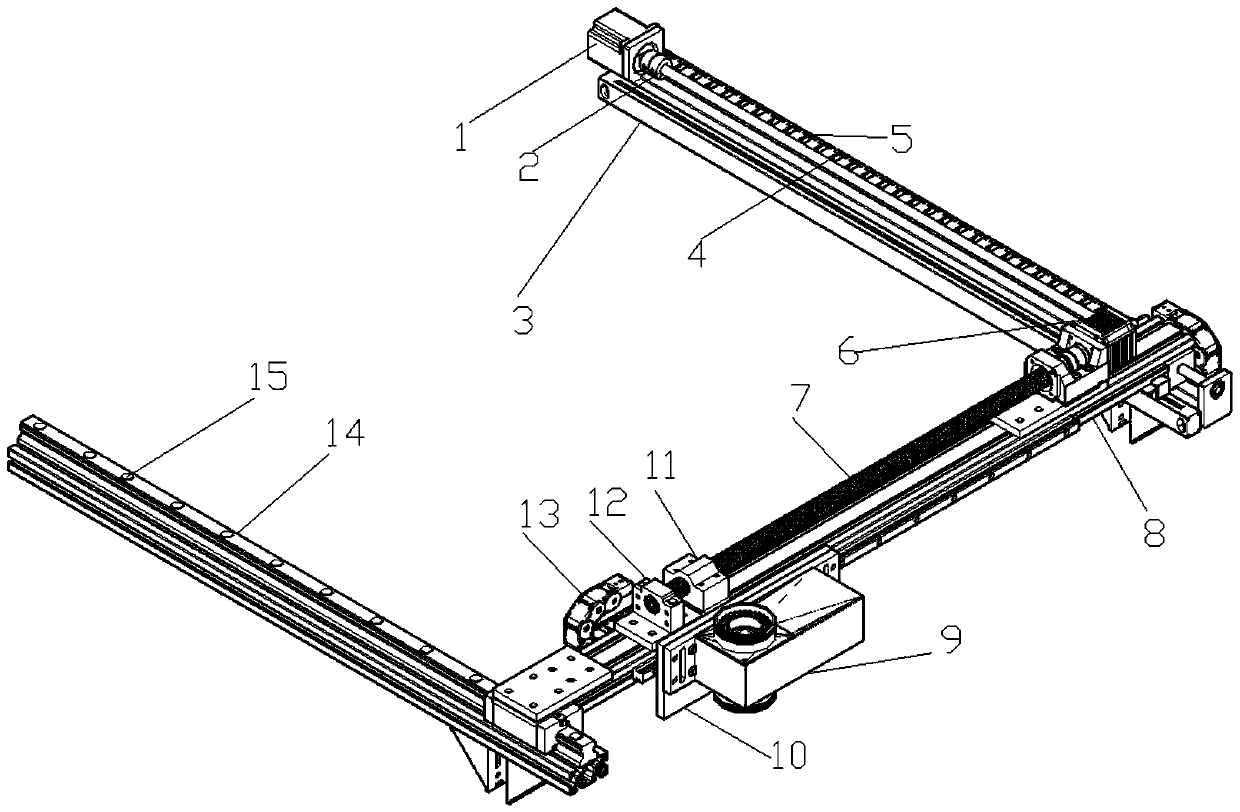

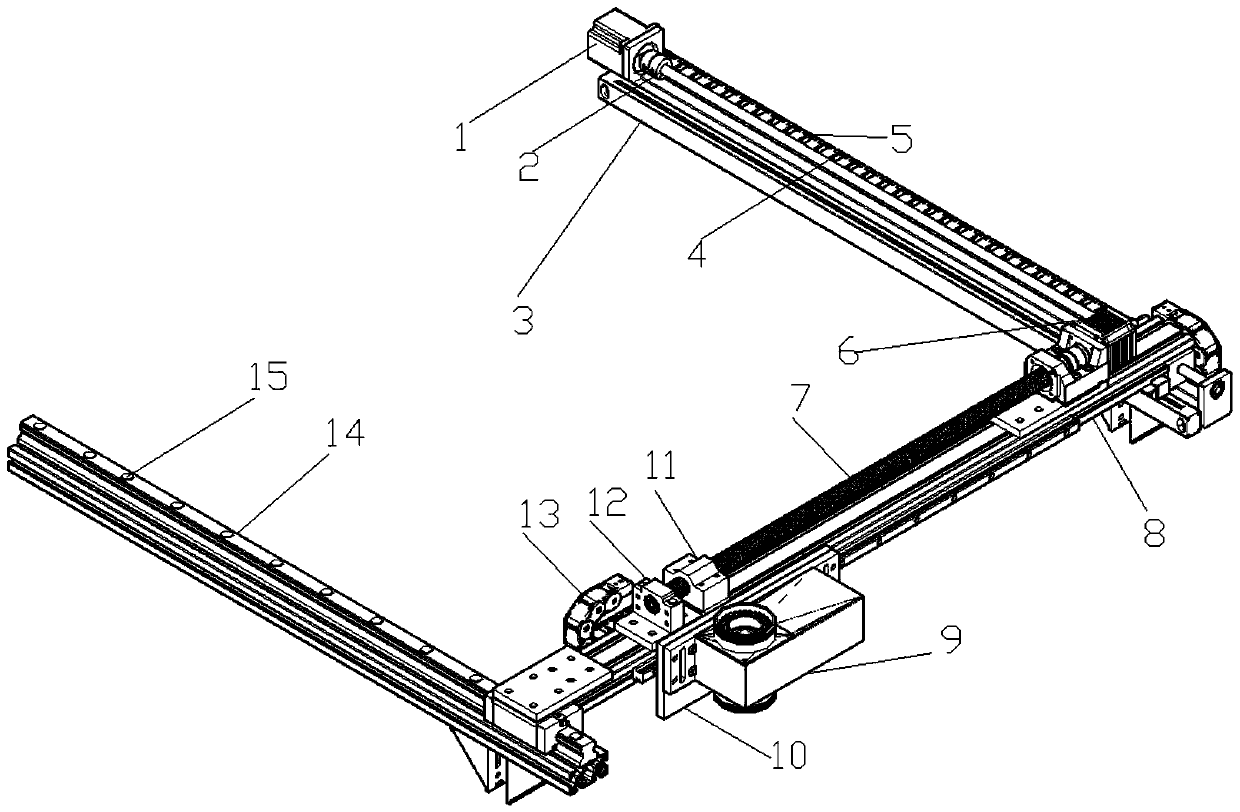

[0029] The coordinate algorithm of the MARK point on the printed board in the high-precision printing machine based on machine vision disclosed by the present invention, wherein:

[0030] The camera moves through a two-dimensional drive mechanism; above the camera is a printed stencil, and below the camera is a PCB board; the printed stencil and the PCB board respectively contain two MARK points (points A and B on the PCB board, and points A and B on the printed stencil) two points C and D); the number of MARK points on the printed stencil and the PCB board are the same, and the positions match; the two matching MARK points on the printed stencil and the PCB board form a group; the two-dimensional drive mechanism includes X moving components , Y moving component, X grating ruler and Y grating ruler; the two-dimensional drive mechanism includes two photoelectric switches located at the mechanical origin, namely the X photoelectric switch and the Y photoelectric switch; the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com