Main conveying device, feeding device and numerical control edging machining center

A transmission device and feeding device technology, applied to metal processing equipment, grinding machines, conveyors, etc., can solve problems such as timing belt offset, plate offset, and processing errors, so as to reduce processing errors, avoid offsets, and improve production The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

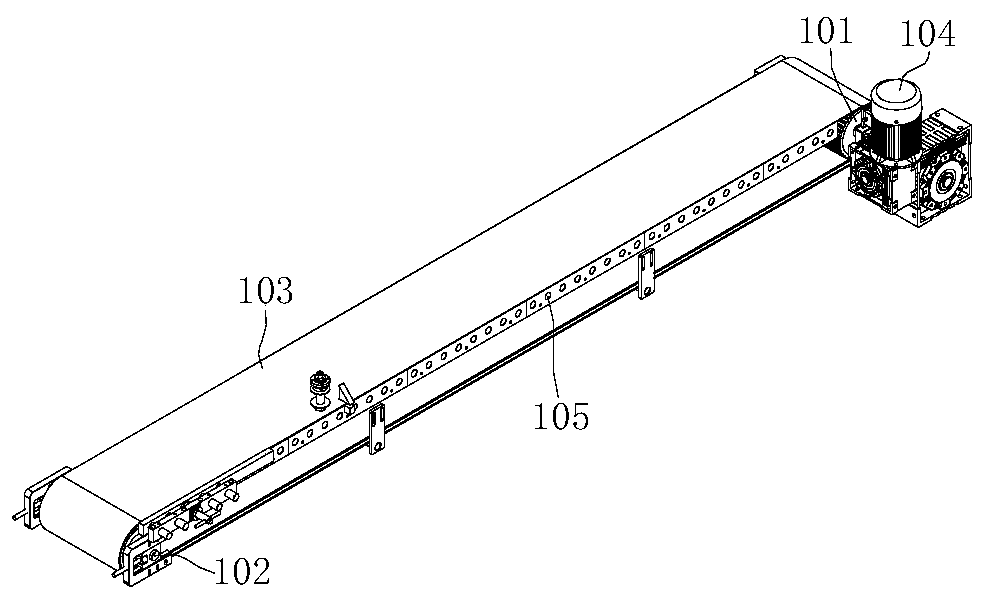

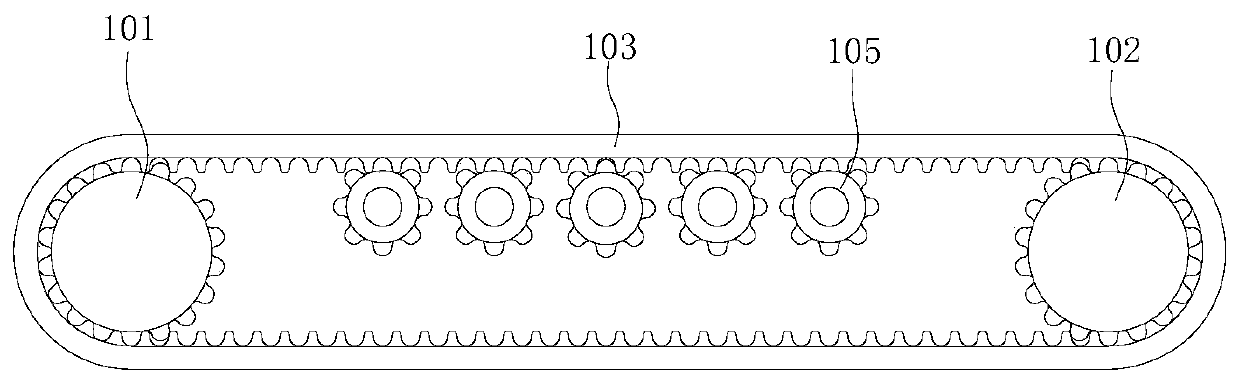

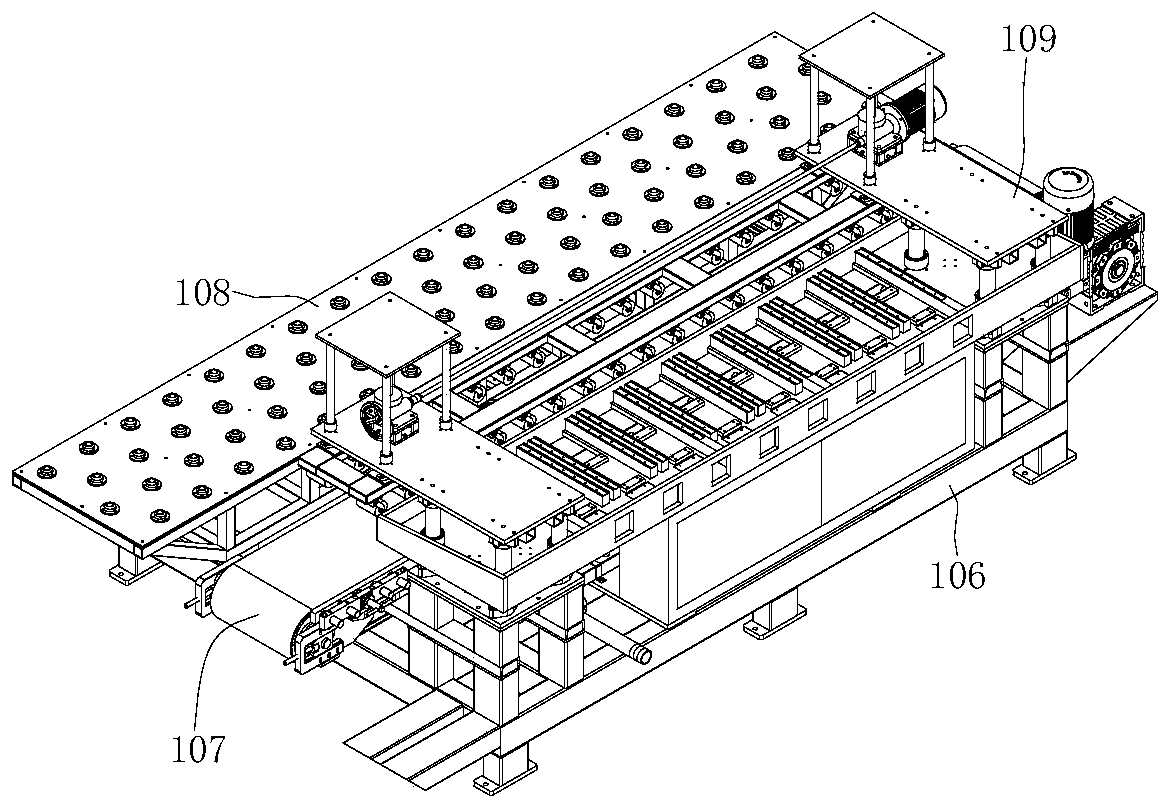

[0044] refer to figure 1 and figure 2 , the present embodiment provides a main transmission device 107, including a frame 106, a motor 104, a driving tooth 101, a driven tooth 102, a conveyor belt 103 and a plurality of rollers 105, a motor 104, a driving tooth 101 and a driven tooth 102 Both are installed on the frame 106, the motor 104 drives and connects the driving gear 101, the conveyor belt 103 is wound between the driving gear 101 and the driven gear 102, the conveyor belt 103 is respectively engaged with the driving gear 101 and the driven gear 102, and a plurality of rollers 105 All are installed on the frame 106, and a plurality of rollers 105 are arranged at intervals along the direction from the driving gear 101 to the driven gear 102, the rollers 105 are engaged with the conveyor belt 103, and the plurality of rollers 105 are all located inside the conveyor belt 103.

[0045] The main transmission device 107 provided in this embodiment utilizes the engagement be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com