Ferrous sulfate crystallization device for sulfuric acid method titanium dioxide

A ferrous sulfate and crystallization device technology, which is applied in the direction of ferric sulfate, solution crystallization, titanium dioxide, etc., can solve the problems of large steam and electric power, high energy consumption, and consumption, and achieve the goals of reducing cooling heat load, uniform particles, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

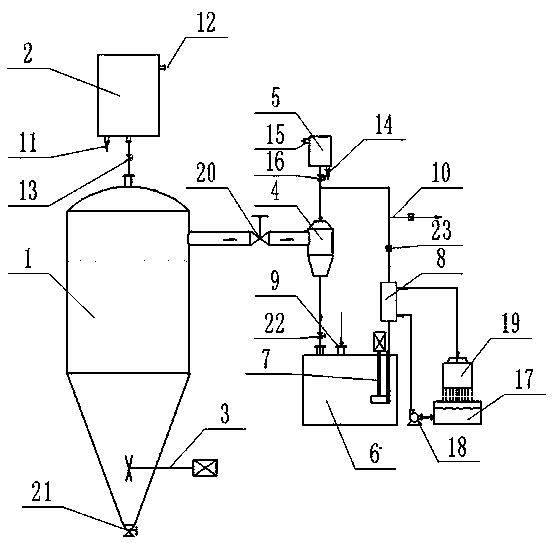

[0028] like figure 1 As shown, a sulfuric acid process titanium white ferrous sulfate crystallization device comprises a crystallization tank 1, the top of the crystallization tank 1 is connected with a first elevated tank 2, the bottom of the crystallization tank 1 is provided with an inlet and outlet, and the crystallization tank 1 The bottom is provided with a side stirring device 3, the top of the crystallization tank 1 is connected with a vacuum ejector 4, the top of the vacuum ejector 4 is connected with a second elevated tank 5, and the bottom of the vacuum ejector 4 is connected with the acid circulation tank 6, so The acid circulation tank 6 is connected to the top of the vacuum ejector 4 through an acid pump 7 and a heat exchanger 8. The acid circulation tank 6 is provided with an acid supplement port 9, and the heat exchanger 8 is connected with a cooling circulation system. An acid outlet 10 is provided between the heat exchanger 8 and the top of the vacuum ejector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com