Pollutant treatment method based on friction catalysis of semiconductor powder

A semiconductor and pollutant technology, applied in the field of pollution control, can solve problems such as low efficiency, difficulty in light entry, poor light transmission, etc., and achieve extensive control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The pollutant treatment method based on semiconductor powder friction catalysis provided by the first embodiment includes the following contents:

[0019] Add 30 mg of commercially available photocatalytic material P25 (titanium dioxide nanopowder) into 30 ml of rhodamine B solution (concentration: 5 mg / L), and the volume of the beaker is 50 ml. Add four magnetic stirring bars with Teflon surfaces in the beaker, and perform magnetic stirring at a speed of 300 revolutions per minute. During the shading period, the temperature was kept at 25°C.

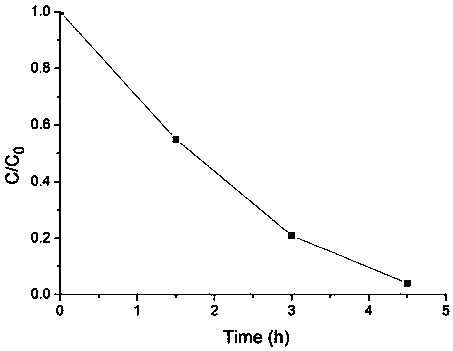

[0020] The concentration change of rhodamine B was analyzed by measuring the absorption spectrum. Such as figure 1 As shown, the test results show that after four and a half hours of stirring, the degradation rate of rhodamine B reaches more than 95%.

Embodiment 2

[0022] The pollution control method based on semiconductor powder friction catalysis provided in the second embodiment includes the following contents:

[0023] 23.66 g of Ba(OH) 2 ·8H 2 O with 6.645 g Sr(OH) 2 ·8H 2 O was dissolved in 500 ml of deionized water, kept at 60°C with a water bath, and stirred, and this solution was called solution A. 34.0 g of Ti(OBu) 4 Dissolve in 250 ml of absolute ethanol, and the resulting solution is called solution B. Solution B was slowly dropped into solution A while stirring vigorously. The white precipitate formed was aged for 3 hours, collected by filtration, and baked at 60 °C for 24 hours. Finally, it was calcined at 500°C for 2 hours in a muffle furnace to obtain Ba 0.75 Sr 0.25 TiO 3 (BST) powder.

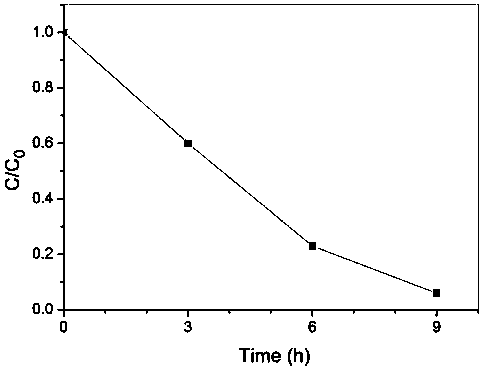

[0024] Add 40 mg of the above-mentioned BST powder into 30 ml of methyl orange solution (concentration: 5 mg / L), and the volume of the beaker is 50 ml. Add four magnetic stirring bars with Teflon surfaces in the beaker, and pe...

Embodiment 3

[0027] The pollutant treatment method based on semiconductor powder friction catalysis provided by the third embodiment includes the following contents:

[0028] Add 40 mg of commercially available zinc oxide micron powder (Tianjin Kermel Company, 2 micron zinc oxide powder) into 30 ml of rhodamine B solution (concentration is 5 mg / L), and the volume of the beaker is 50 ml. Add four magnetic stirring bars with Teflon surfaces in the beaker, and perform magnetic stirring at a speed of 300 revolutions per minute. During the shading period, the temperature was kept at 25°C.

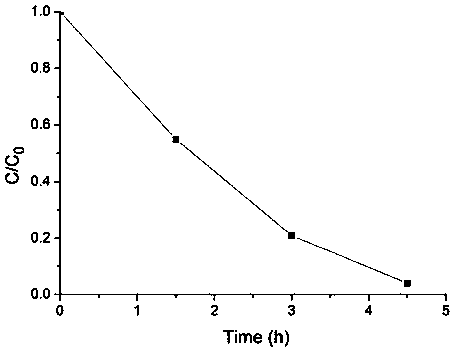

[0029] The concentration change of rhodamine B was analyzed by measuring the absorption spectrum. The test results show that after three hours of stirring, the degradation rate of rhodamine B reaches more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com