Composite photocatalyst CN-CNI as well as preparation method and application thereof

A technology of catalyst and compound light, which is applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc. Low performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Accurately weigh 2.0g (DCDA) dicyandiamide and pour it into a clean and dry small beaker, then accurately weigh 1.0g ammonium iodide under light-proof conditions and pour it into a small beaker to mix with dicyandiamide, Then use a graduated cylinder to measure 10mL of distilled water and add it to the small beaker, then shake it well, put the small beaker into a digital display constant temperature water bath at 80°C and evaporate it to dryness. During the evaporation process, the small beaker should be shaken properly, and the sample will be evaporated to dryness. It takes about 5 hours. After evaporating to dryness, put the sample in an electric blast constant temperature drying oven to dry for about an hour, then take out the small beaker, crush the sample and grind it in a mortar;

[0076] (2) Put the ground sample into a clean small crucible, cover the lid, and put it into the muffle furnace (when the temperature of the muffle furnace is below 150°C, put the sa...

Embodiment 2~10

[0080] The operation method of embodiment 2~10 is similar to embodiment 1, and difference only is that the add-on of dicyandiamide in step (2) is successively respectively 2.0g, 4.0g, 8.0g, 0.1g, 0.2g, 0.3g, 0.01g, 0.02g and 0.05g, the prepared samples are respectively recorded as CNI-CN 2.0 、CNI-CN 4.0 、CNI-CN 8.0 、CNI-CN 0.1 、CNI-CN 0.2 、CNI-CN 0.3 、CNI-CN 0.01 、CNI-CN 0.02 、CNI-CN 0.05 .

experiment example 1

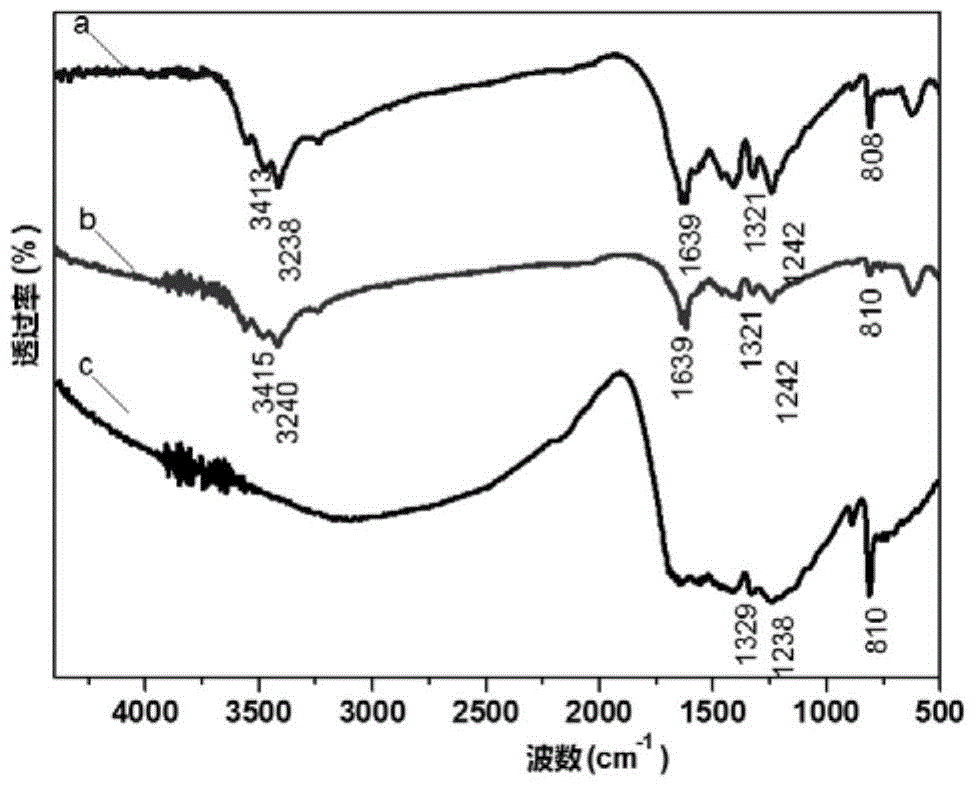

[0087] Infrared Spectrometry of Experimental Example 1 Sample

[0088] The samples used in this experimental example are the samples prepared in Example 10, Comparative Example 1 and Comparative Example 2.

[0089] Operation method: use WQF-501 Fourier transform infrared spectrometer to carry out infrared spectrum characterization experiment (KBr tablet) on the above samples, the results are as follows figure 1 As shown, among them,

[0090] Curve a represents the sample that embodiment 10 makes (CNI-CN 0.05 );

[0091] Curve b represents the sample (CNI) that comparative example 1 makes;

[0092] Curve c represents the sample (CN) prepared in Comparative Example 2.

[0093] Depend on figure 1 It can be seen that:

[0094] Sample at 810cm -1 、1238cm -1 and 1329cm -1 There are strong absorption peaks at all places, among which, the wavenumber is 810cm -1 The absorption peak can be attributed to the bending vibration of the triazine ring, it can be considered that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com