Compound subsurface flow constructed wetland with high drop difference and adjustable water outflow

A technology of artificial wetland and high drop, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as complex water flow direction, large head loss, and easy blockage, etc., to achieve The overall anti-clogging performance is good, the effect of promoting plant growth and uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

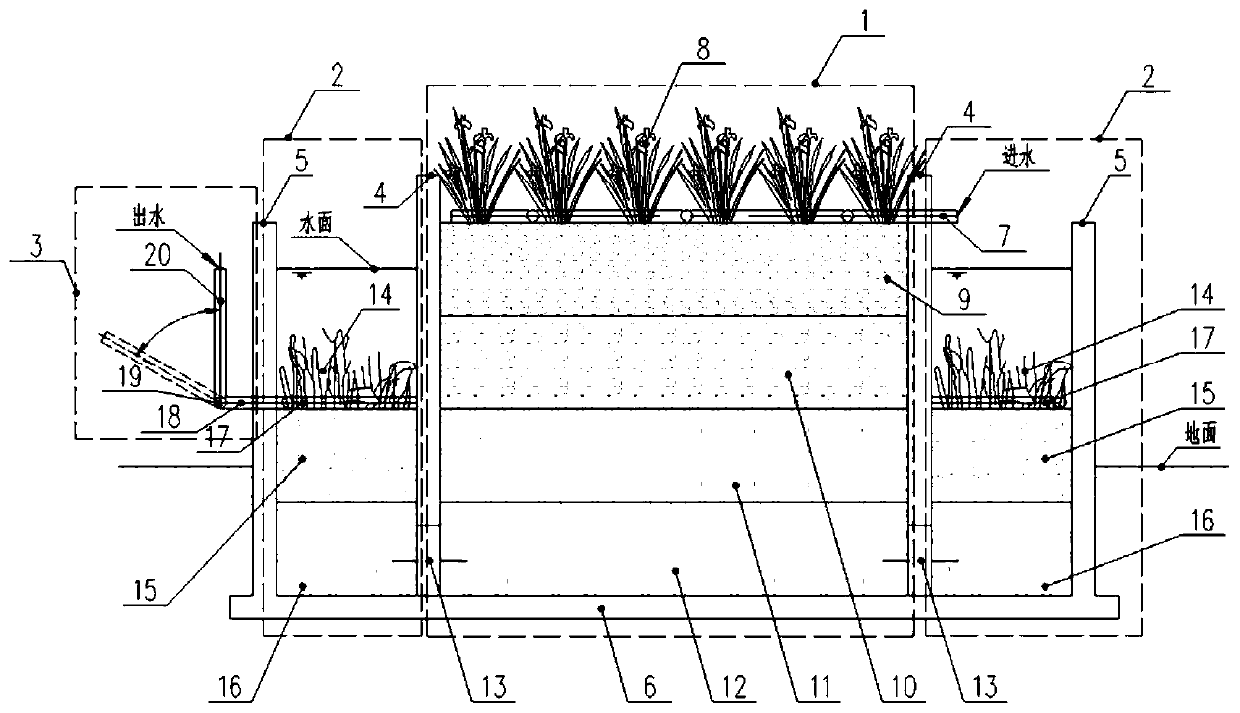

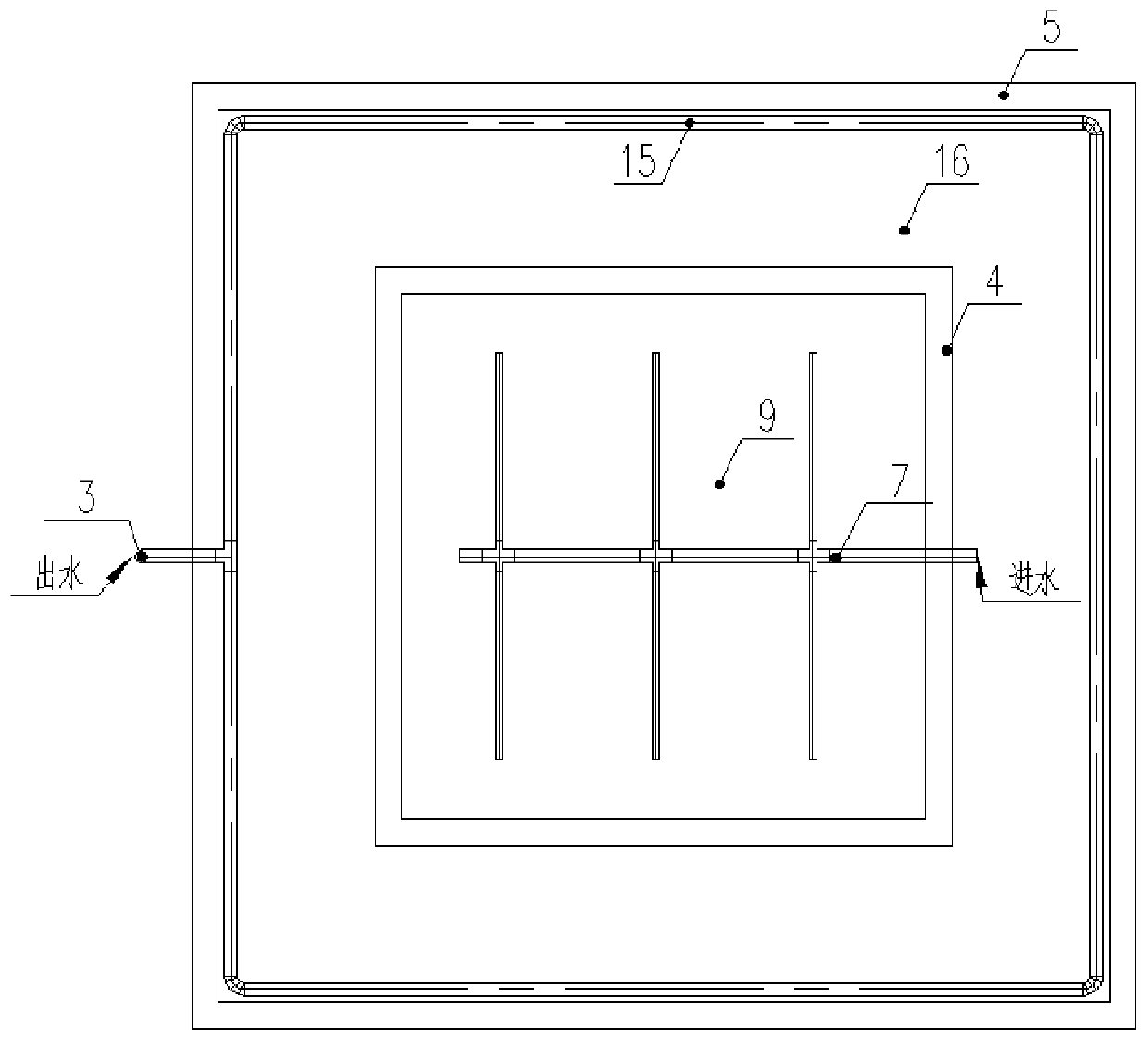

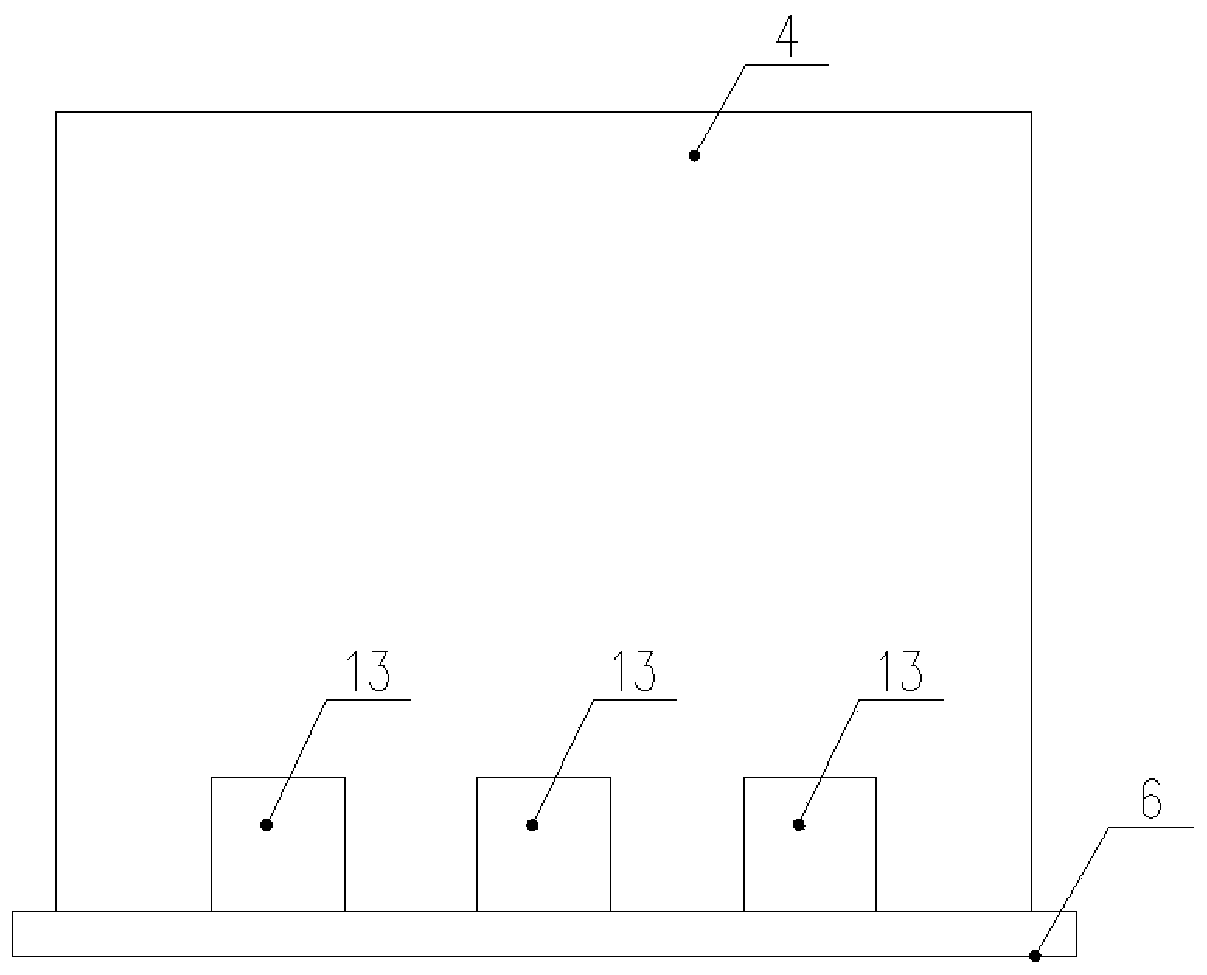

[0032] Such as Figure 1~3 As shown in the figure, a composite subsurface flow artificial wetland with high drop and adjustable discharge water includes a downward wet area 1, and an upward wet area 2 is circularly arranged around the downward wet area 1, and the bottom of the downward wet area 1 is evenly arranged with a 2 A water hole 13 connected at the bottom, a water distribution pipe 7 is installed on the top of the downward wet area 1, and the vegetation layer 14 of the upward pool, the filling layer 15 of the first upward pool and the second upward pool are sequentially arranged in the upward wet area 2 from top to bottom Filling layer 16, the top of the filling layer 15 of the first upward pool is provided with a water collection pipe 17, the water collection pipe 17 is connected to one end of the water outlet horizontal pipe 18, and the other end of the water outlet horizontal pipe 18 passes through the upward wet area 2 and then passes through the swivel elbow 19 and...

Embodiment 2

[0052] The specifications of the descending wet area 1 are: length × width = 5m × 5m.

[0053] The vegetation layer 8 of the descending pond is canna, and the planting density is 9 plants / ㎡.

[0054] The first descending pool filler layer 9 is gravel filler with a particle size of 8-10mm, and the thickness is 350mm.

[0055] The second down tank filler layer 10 is crushed stone filler with a particle size of 12-15 mm, and a thickness of 350 mm.

[0056] The third down tank filler layer 11 is gravel filler with a particle size of 20-30 mm, and a thickness of 350 mm.

[0057] The fourth down tank filler layer 12 is gravel filler with a particle size of 50-70 mm, and a thickness of 350 mm.

[0058] The water distribution pipe 7 is a PE perforated pipe of DN80, the diameter of the water outlet hole is 8mm, and the hole distance between adjacent water outlet holes is 150mm.

[0059] Partition wall 4 is a reinforced concrete partition wall with a height of 1.6m. The width and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com