Folding table top structure of sewing machine

A table structure and sewing machine technology, which is applied in the field of sewing machines, can solve the problems of not being able to fully meet the needs of the tabletop extension and poor adjustability, and achieve the effects of convenient packaging and transportation, reduced area, and minimized size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

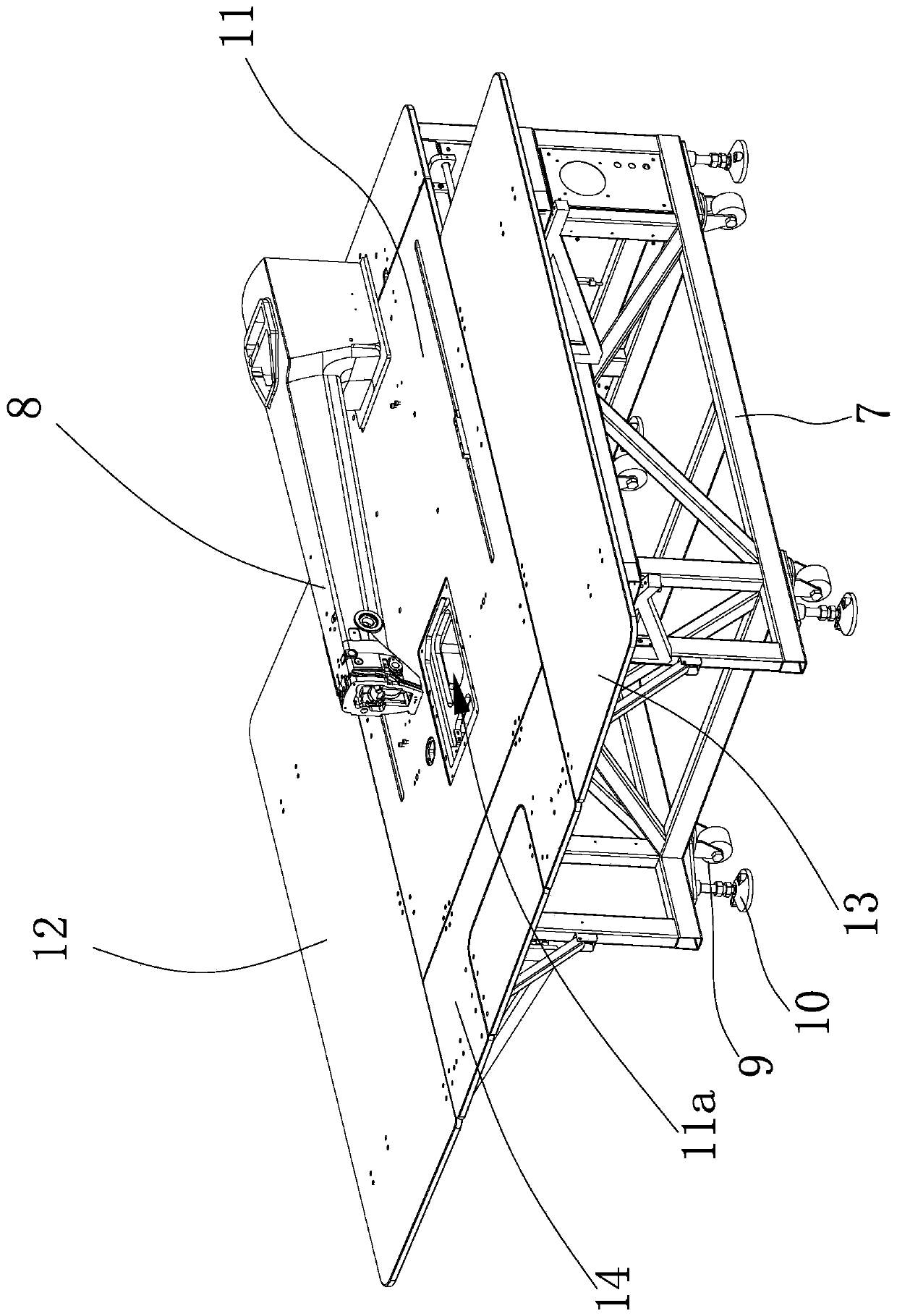

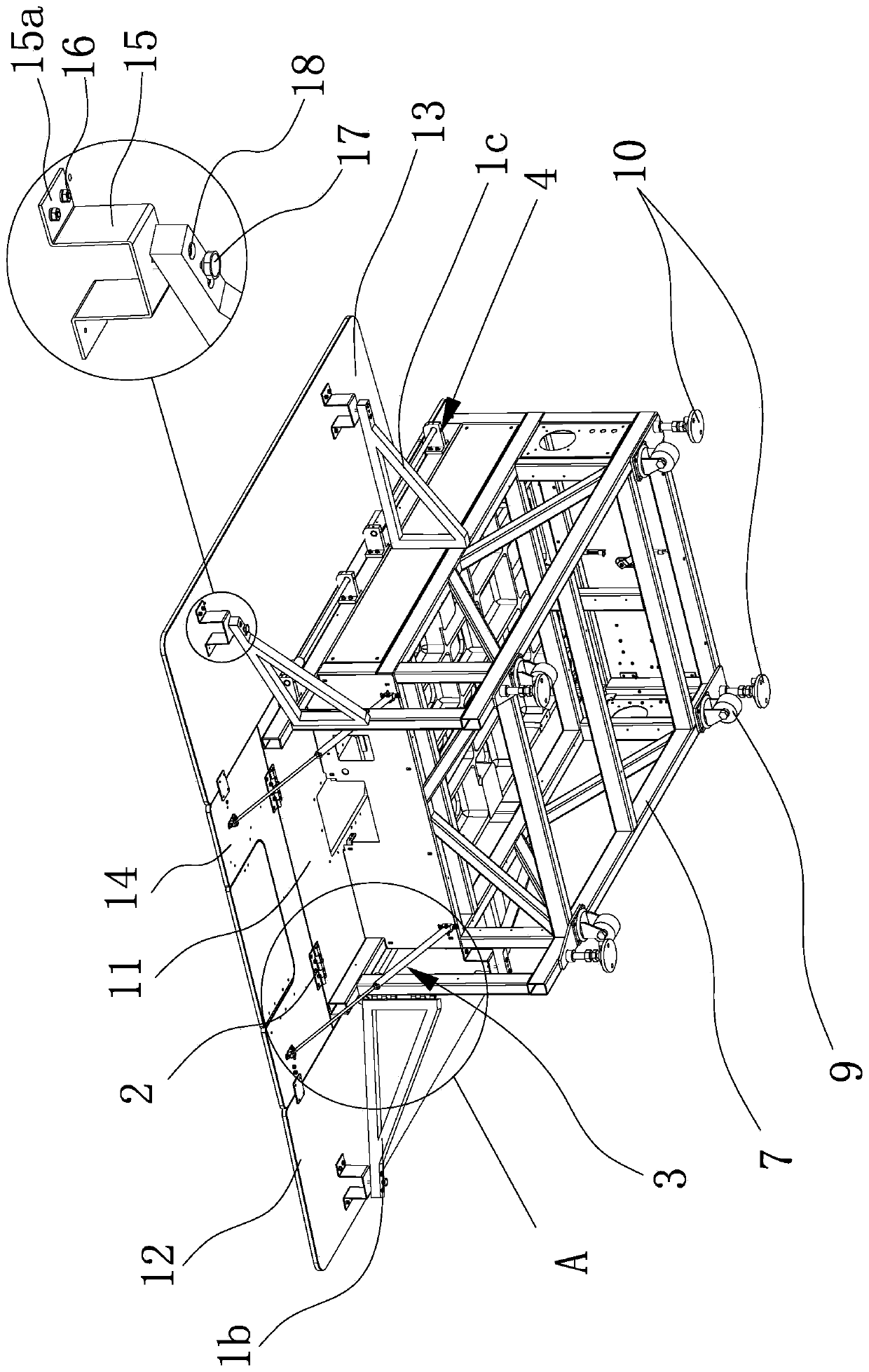

[0040] Such as Figure 1 to Figure 3 As shown, the sewing machine in this embodiment includes a frame 7 on which a machine head 8 is fixed, and the bottom of the frame 7 is provided with rollers 9 and support feet 10 capable of lifting. The folding table structure includes a rectangular main table Plate 11, the main plate 11 is provided with a through hole 11a facing the head of the machine head 8, the main plate 11 is fixed on the upper end of the frame 7, and one end of the main plate 11 is connected with a front auxiliary plate through a hinge 12. Platen 14, left auxiliary platen 12 and right auxiliary platen 13 are respectively provided on both sides of main platen 11, between left auxiliary platen 12 and main platen 11, between right auxiliary platen 13 and main platen 11 Both of them are connected through the connecting assembly 4 that can make the left auxiliary table 12 and the right auxiliary table 13 swing and fold, and the left auxiliary table 12 and the right auxil...

Embodiment 2

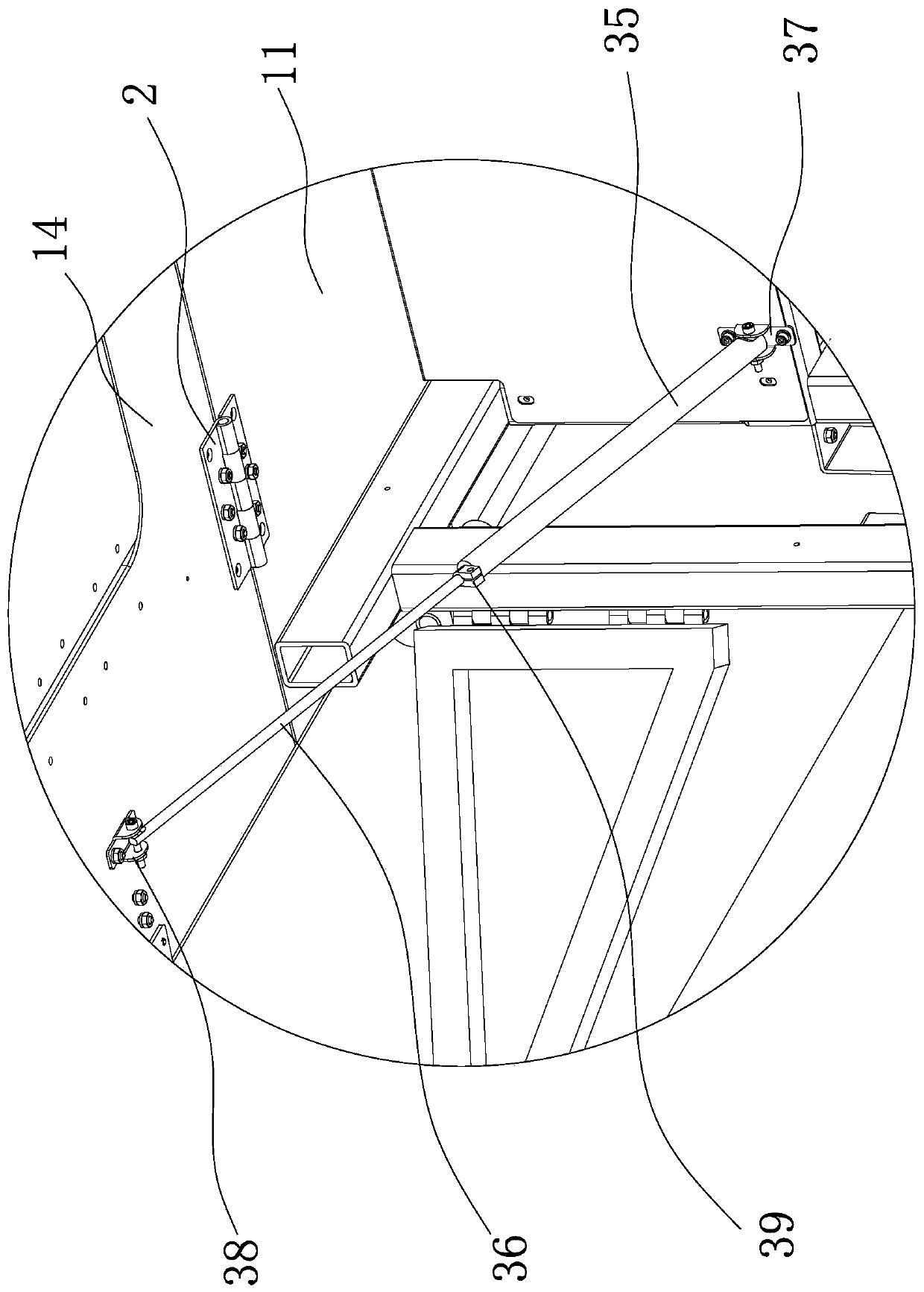

[0047] Such as Figure 4 with Figure 5 As shown, the present embodiment is substantially the same as the first embodiment, the difference is that the support assembly 3 in the present embodiment includes a support rod 31, a support rod 2 32, a fixed seat 33 fixedly connected with the frame 7 and a The fixed seat 2 34 that the bottom of the front auxiliary plate 14 is fixed; one side of the support rod 31 has a groove 31a, and one end of the support rod 31 is hinged with one side of the support rod 2 32 and the support rod 2 32 is embedded Into the groove 31a, the other end of the support rod one 31 is hinged to the second fixing seat 34, and the other end of the support rod two 32 is hinged to the first fixing seat 33.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap