Fan blades, fan assembly, air duct part and air conditioner

A technology of air duct components and air duct parts, which is applied in the fields of fan components, fan blades, air duct components and air conditioners, can solve the problems of reverse flow, large volume and poor air exhaust effect, and avoid being exposed to the inside of the air duct. , Reduce the overall volume, reduce the effect of wind noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

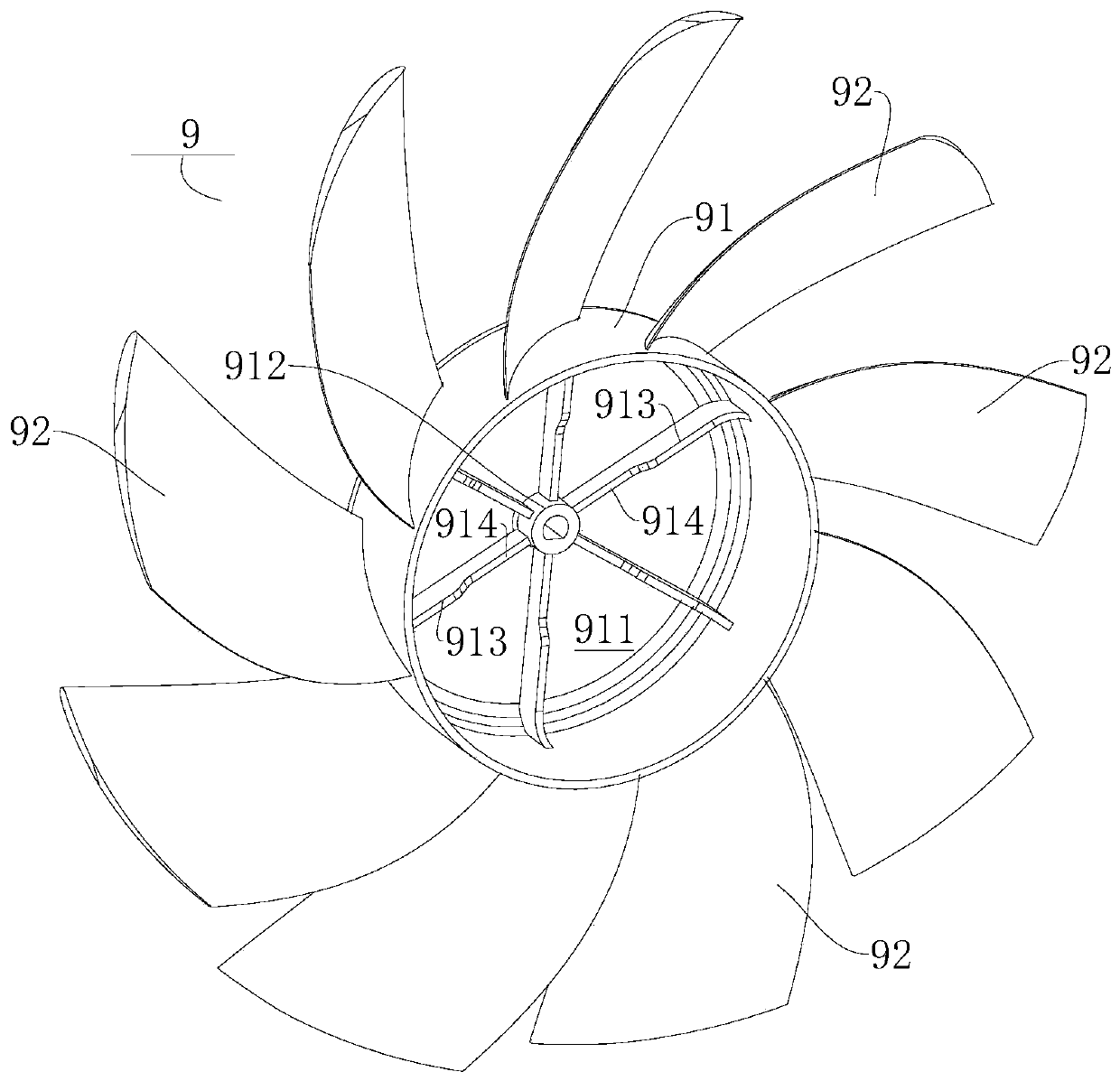

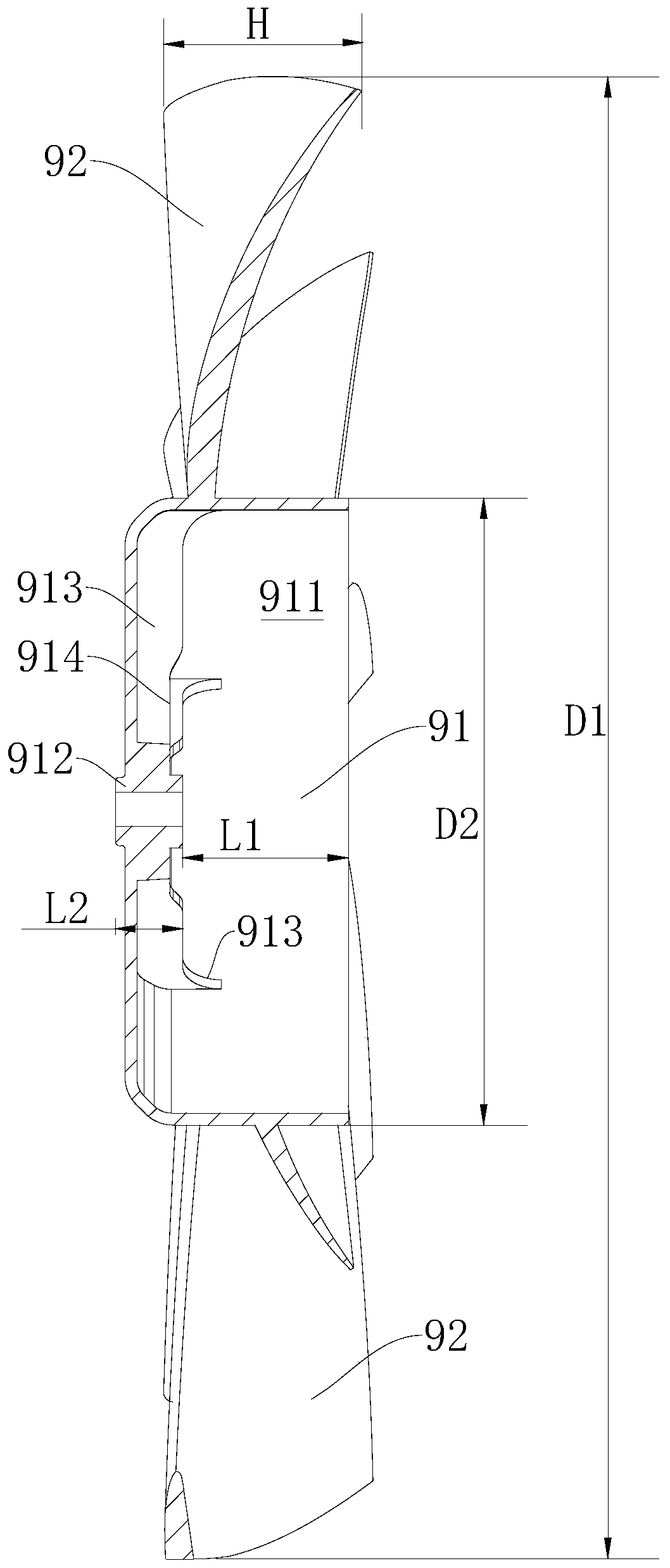

[0097] In this embodiment, in the direction of the axis of rotation of the hub 91, the height of the blade 92 is H, and the point on the blade 92 farthest from the axis of rotation of the hub 91 is located on a reference circle whose diameter is D1. In order to test the influence of H and D1 on the air volume and noise of the air conditioner 9100, take D1=360mm, 800 square air volume as an example to test, the experiment is as follows:

[0098] Table 1

[0099]

[0100]

[0101] It can be seen from the above table that when 0.05≤H / D1≤0.5, the air outlet noise of the air conditioner 9100 is small and the energy consumption is low. When 0.05≦H / D1≦0.5, the volume of the fan blade 9 can also be reduced.

Embodiment 2

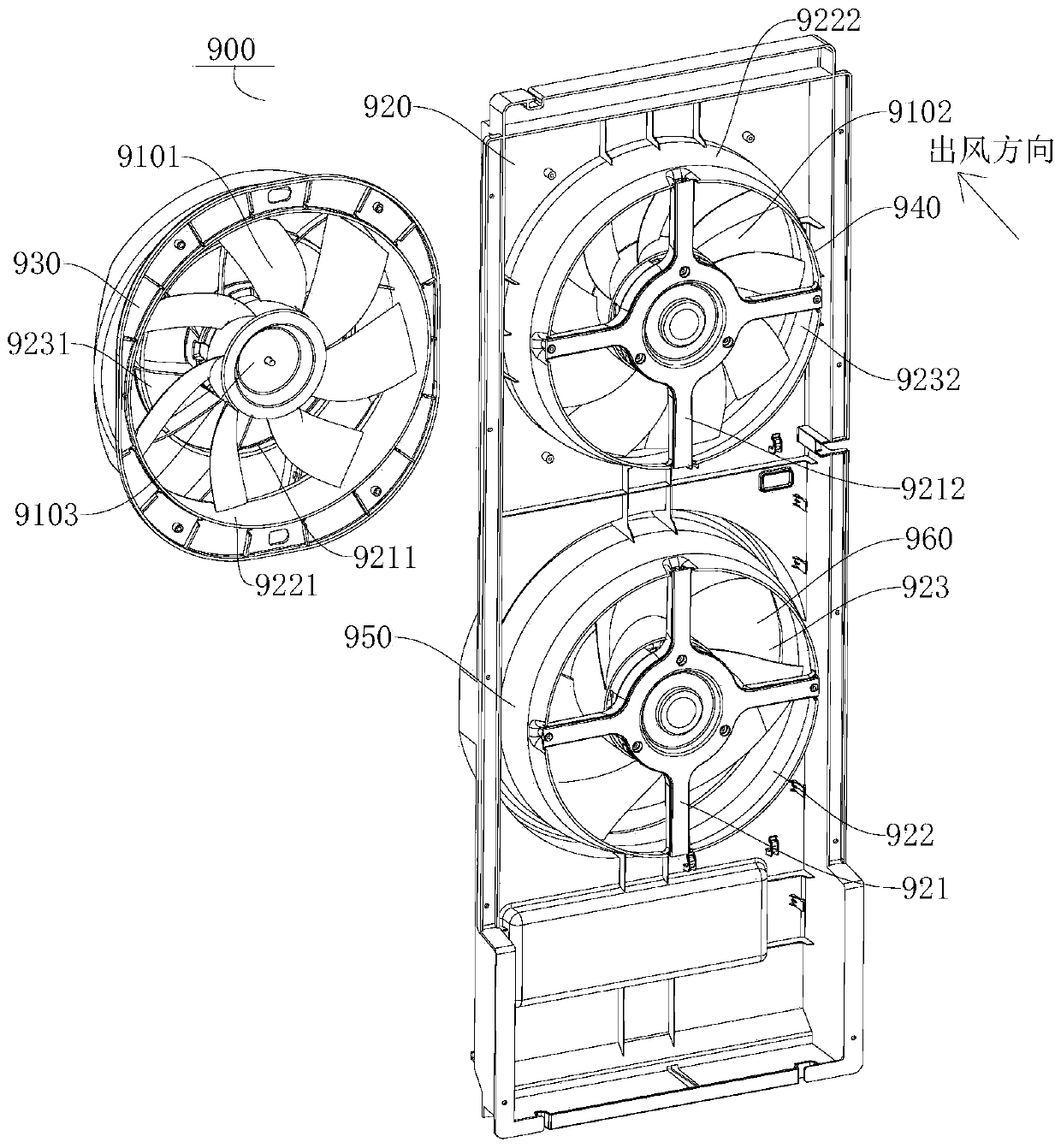

[0103] In this embodiment, in the direction of the axis of rotation of the hub 91, the height of the blade 92 is H, and the point on the blade 92 that is farthest from the axis of rotation of the hub 91 is located on the reference circle, and the diameter of the reference circle is D1. The vertical distance between the first fan assembly 9101 and the second fan assembly 9102 is L4. In order to test the influence of L4 on the noise of the air conditioner 9100, take D1=360mm, H=44mm, 1200 square air volume as an example to test, the experiment is as follows:

[0104] Table 2

[0105]

[0106] It can be seen from the above table that when 0.025≤L4 / D1≤0.16, the air outlet noise of the air conditioner 9100 is small and the energy consumption is low.

Embodiment 3

[0108] In this embodiment, in the direction of the axis of rotation of the hub 91, the height of the blade 92 is H, and the point on the blade 92 that is farthest from the axis of rotation of the hub 91 is located on the reference circle, and the diameter of the reference circle is D1. The minimum distance between 92 and the motor support 921 is L3.

[0109] In order to test the influence of L3 on the noise of the air conditioner 9100, take D1=360mm, H=44mm, 1200 square air volume as an example to test, the experiment is as follows:

[0110] table 3

[0111]

[0112] For L3, it has been verified by theory and test that the smaller L3 is, the greater the air volume of the fan assembly at the same speed, and the lower the fan noise is at the same air volume. However, considering the possible errors or deformations in assembly, transportation and fan operation, in order to To avoid interference between the blades and the inner wall of the air duct, L3 should not be too large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com