High temperature shut-off valve

A cut-off valve and high-temperature technology, which is used in the field of high-temperature non-oxidizing gas control and high-temperature cut-off valves, can solve problems such as insufficient reliability, and achieve the effects of ensuring sealing, increasing reliability, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

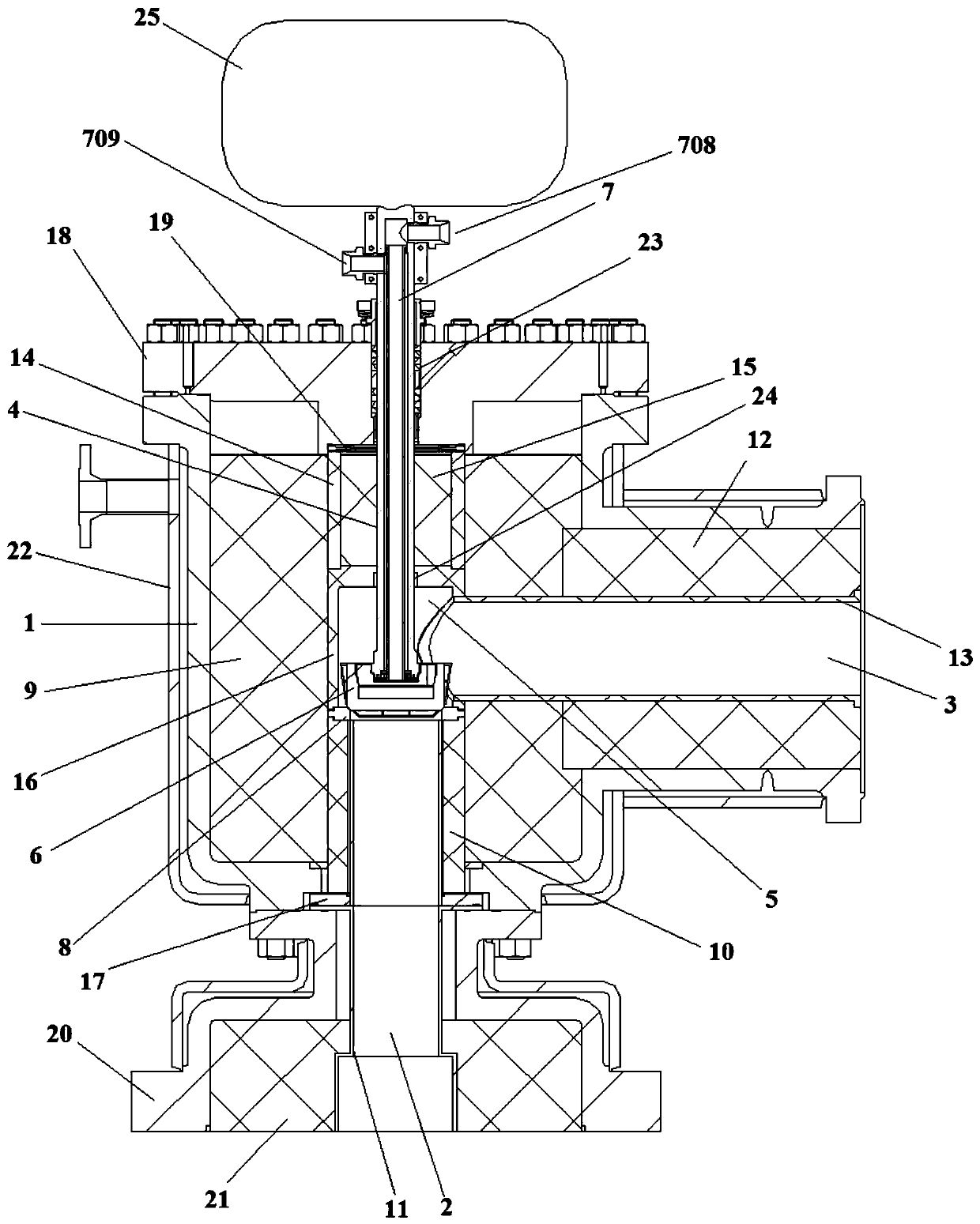

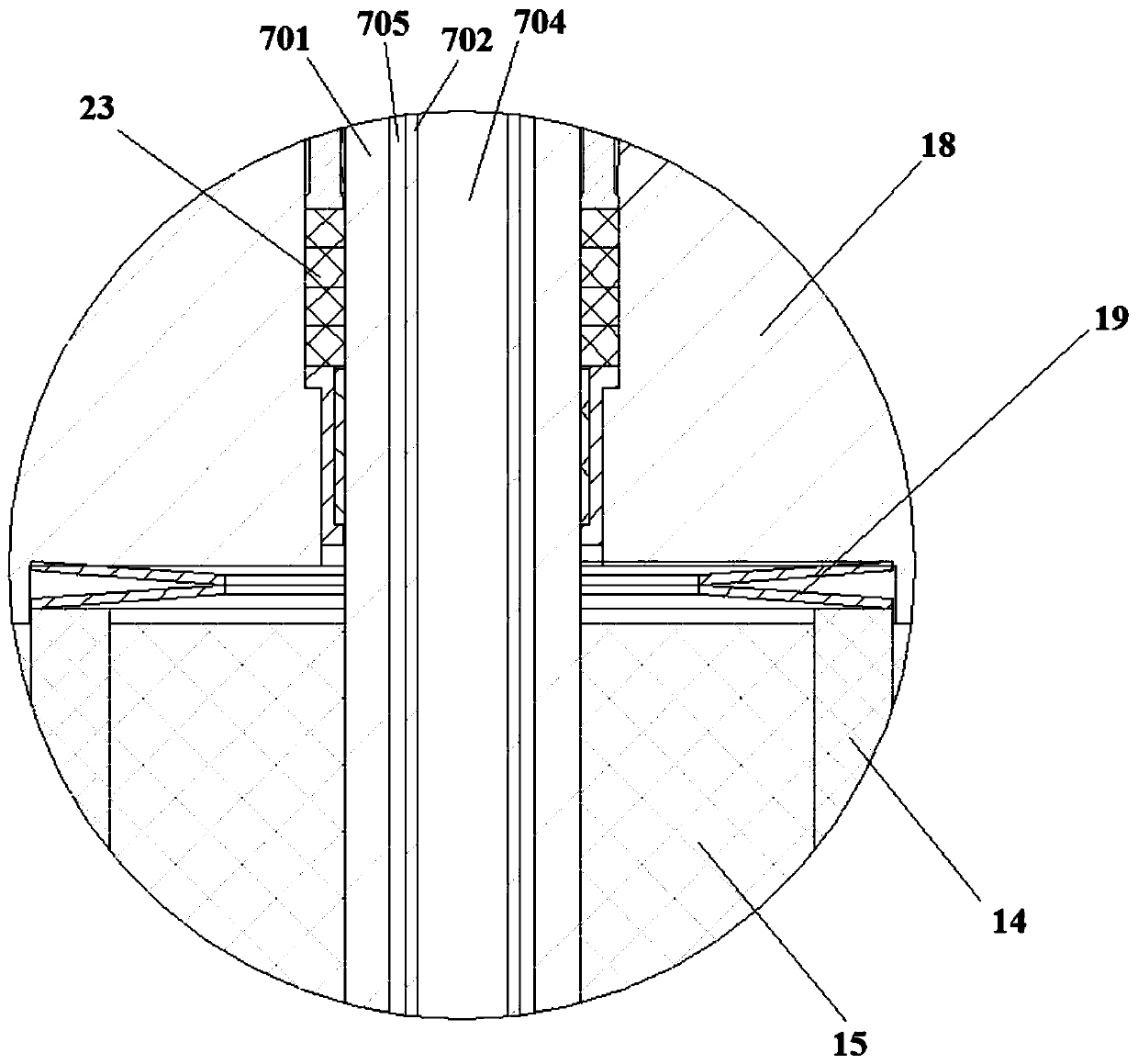

[0039] This embodiment provides a high temperature cut-off valve, such as Figure 1 to Figure 4 As shown, including the valve housing 1, the lower part of the valve housing 1 is vertically provided with a high-temperature medium inlet channel 2, the valve housing 1 is horizontally provided with a high-temperature medium outlet channel 3, and the upper part of the valve housing 1 is vertically arranged A valve stem cavity 4 coaxially arranged with the high-temperature medium inlet channel 2 is provided. The high-temperature medium inlet channel 2, the high-temperature medium outlet channel 3 and the valve stem cavity 4 are connected through the valve core cavity 5, and the valve core cavity 5 A valve core assembly 6 is arranged inside, and the valve core assembly 6 is connected to one end of the valve stem 7, and the other end of the valve stem 7 extends vertically from the valve stem chamber 4 to the top of the valve housing 1;

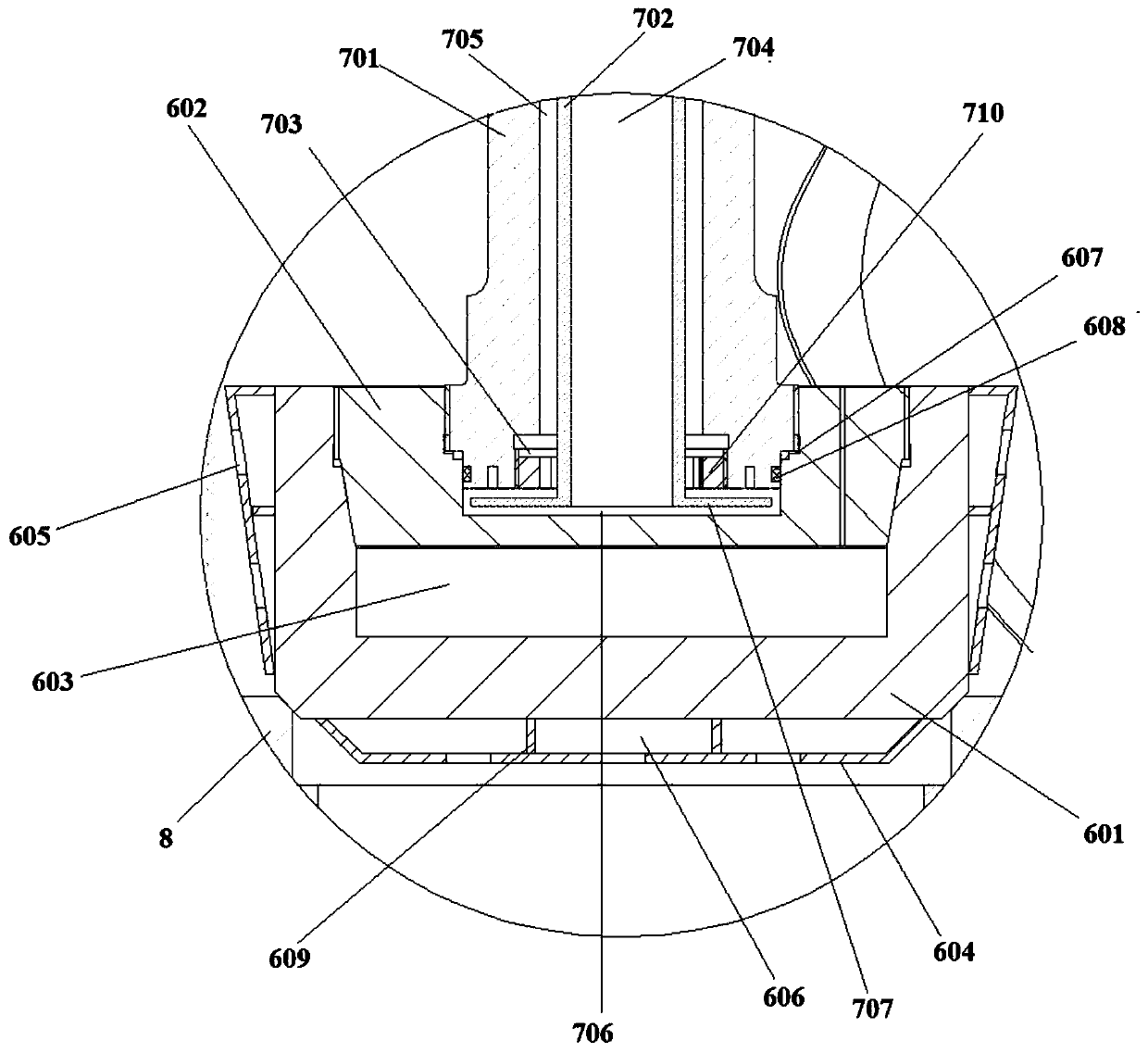

[0040] The spool assembly 6 includes a spool 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com