Method for detecting quality of grouting of sleeve of prefabricated concrete structure

A concrete structure and sleeve grouting technology, which is applied in the direction of structural elements, measuring devices, and preparation of test samples, can solve the problems of easy loss of control of quality, inability to conduct random sampling inspections, use conditions, inspection accuracy, and limitations of convenience and other issues, to achieve the effect of non-destructive testing technology, easy promotion and applicability, and fast and efficient testing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

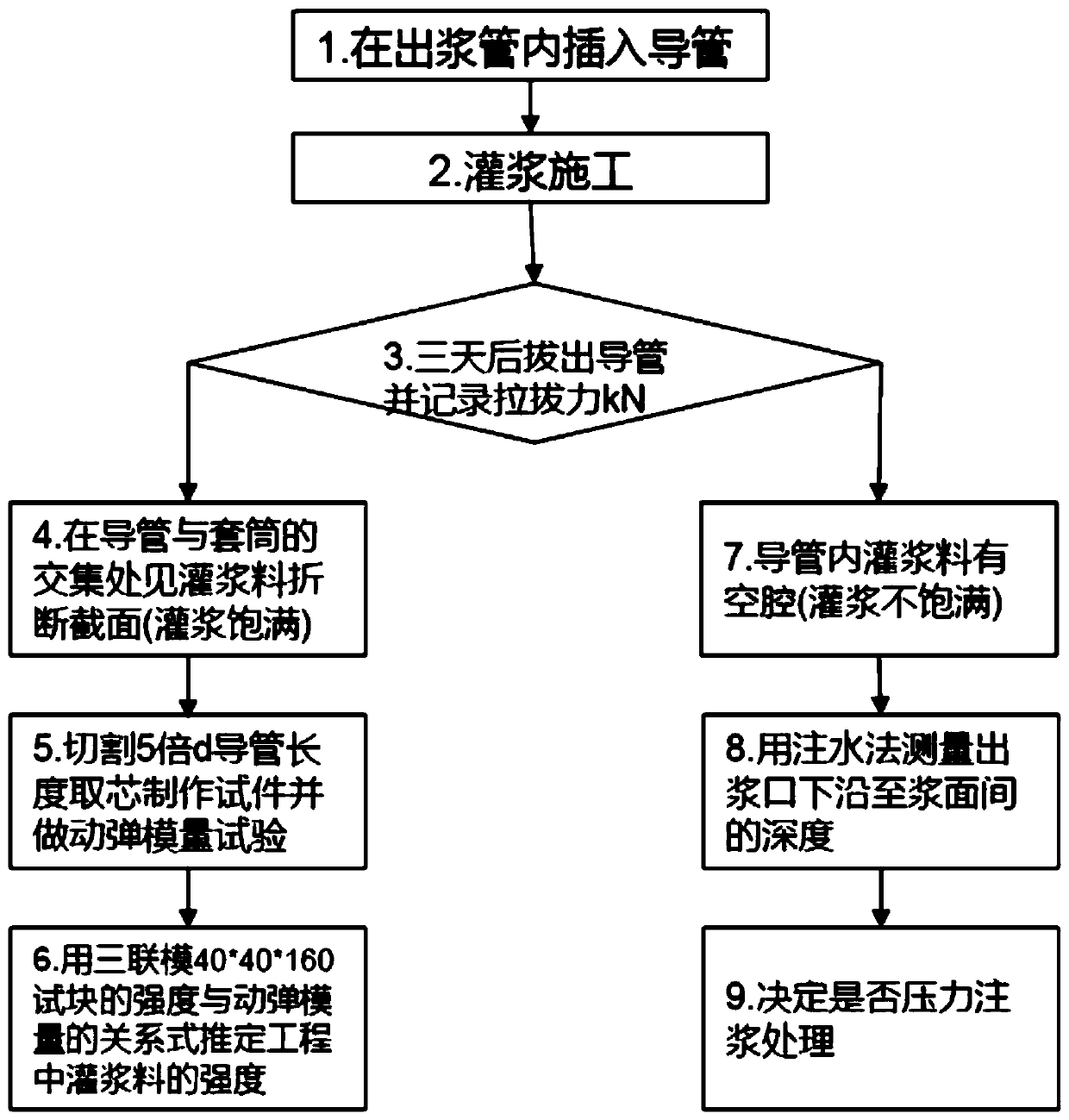

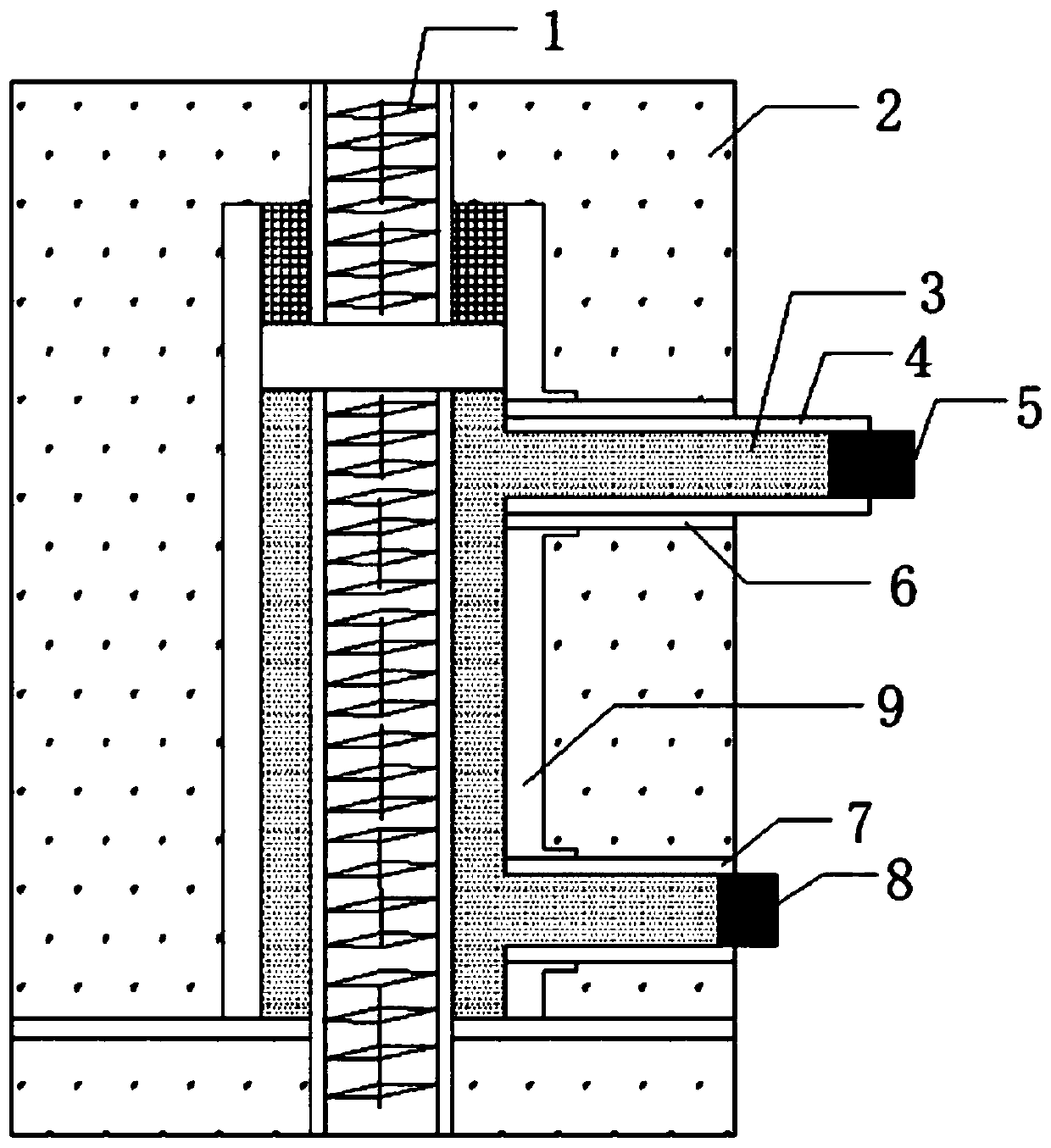

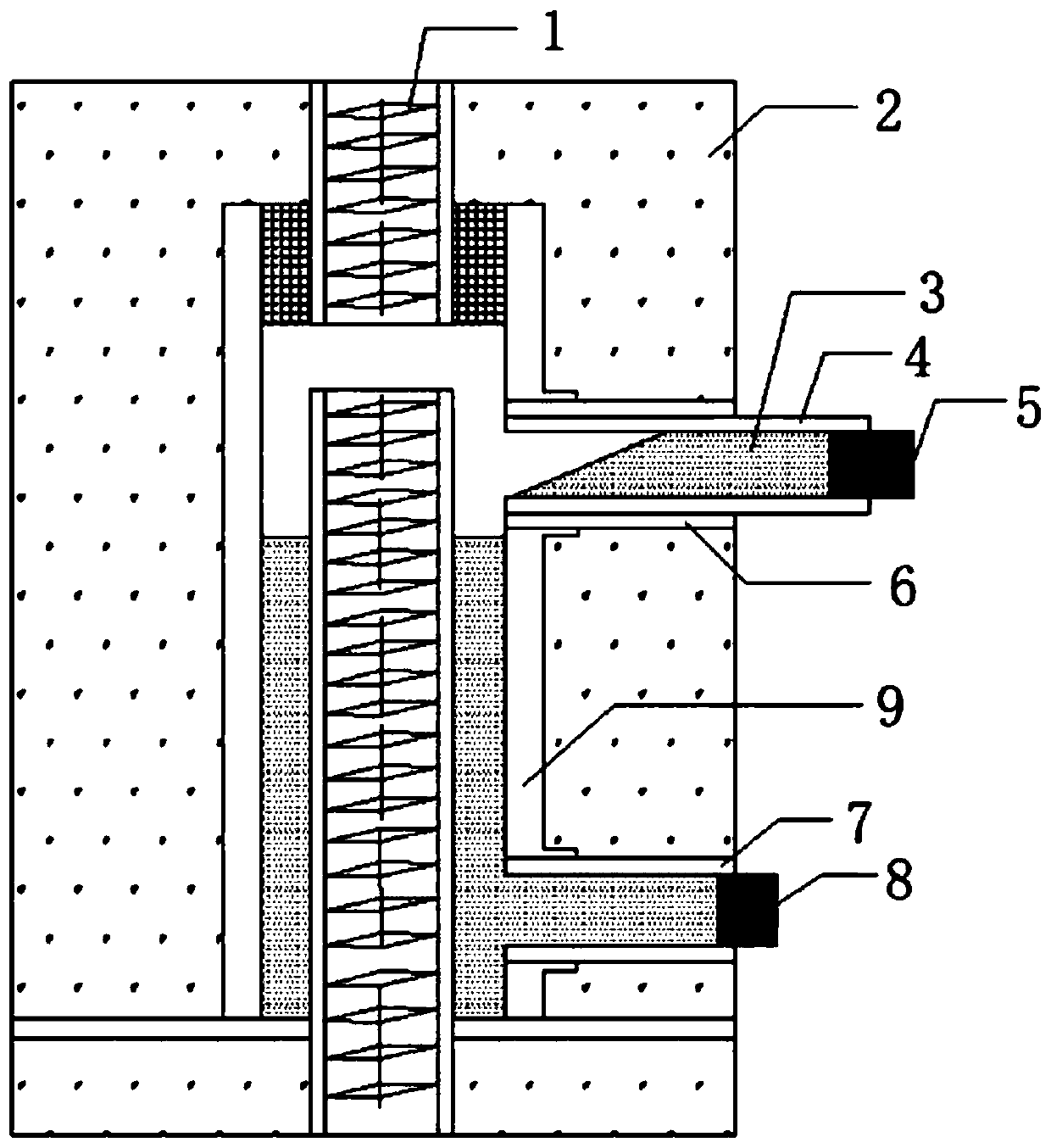

[0032] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0033] The invention provides a method for detecting the pouring compactness and solid strength and material of sleeve grouting material in an assembled concrete structure. The grouting material is the grouting material for the sleeve grouting connection of steel bars in the assembled concrete structure. The method includes the following steps: attached figure 1 The following steps are shown:

[0034] 1) Before the grouting process, insert a conduit as deep as the inner wall of the sleeve into the grout outlet pipe of the original sleeve, and the outer diameter of the conduit is smaller than the inner diameter of the grout outlet pipe of the sleeve;

[0035] 2) The conduit is pulled out after the grouting connection construction is completed and the final setting age of the grouting material is greater than 3 days;

[0036] 3) When the conduit is pulled out, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com