Easy-to-strip flat cable and preparation process thereof

A preparation process, flat technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of difficult maintenance, low construction efficiency, easy crossing and winding of wiring, etc., to improve tensile performance, improve quality, and avoid uneven thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

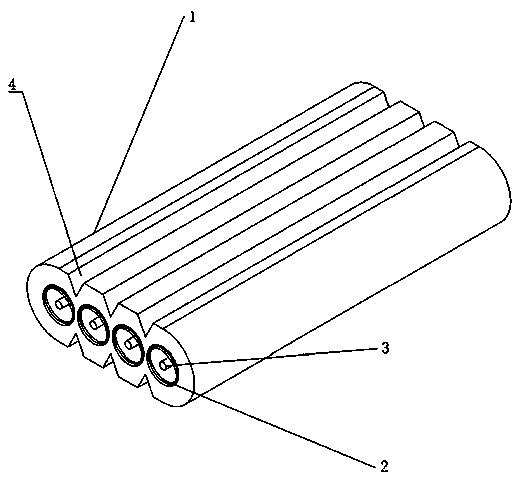

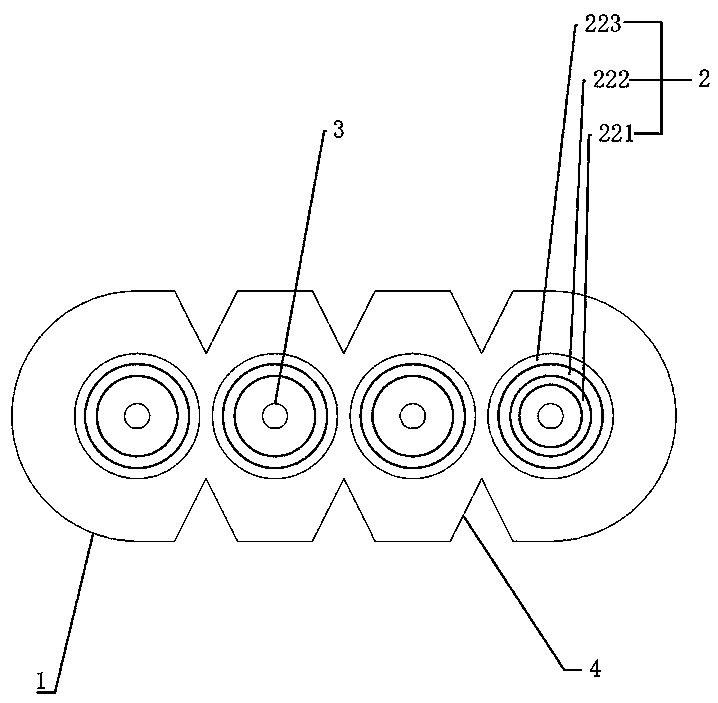

[0042] Embodiment 1, an easy-to-open flat optical cable, such as figure 1 , the optical fiber in the optical cable of the present invention adopts a new type of 200 μm G657A2 optical fiber, the prepared optical cable has a small outer diameter and a small bending radius, and can be laid at any angle in the equipment, including several optical fibers 3, and several optical fibers 3 are equipped with optical fiber protective sleeves 2. Several optical fiber protective sleeves 2 are arranged side by side and parallel to each other. Each optical fiber protective sleeve 2 is installed in the same subunit outer sheath 1. There are several grooves 4 distributed on the upper and lower surfaces of the subunit outer sheath 1. The grooves 4 are interposed Between the adjacent optical fiber protective sleeves 2 and recessed toward the inner optical fiber 3, the outer sheath of the optical cable of the present invention is flat, and at the same time a certain number of grooves are distribut...

Embodiment 2

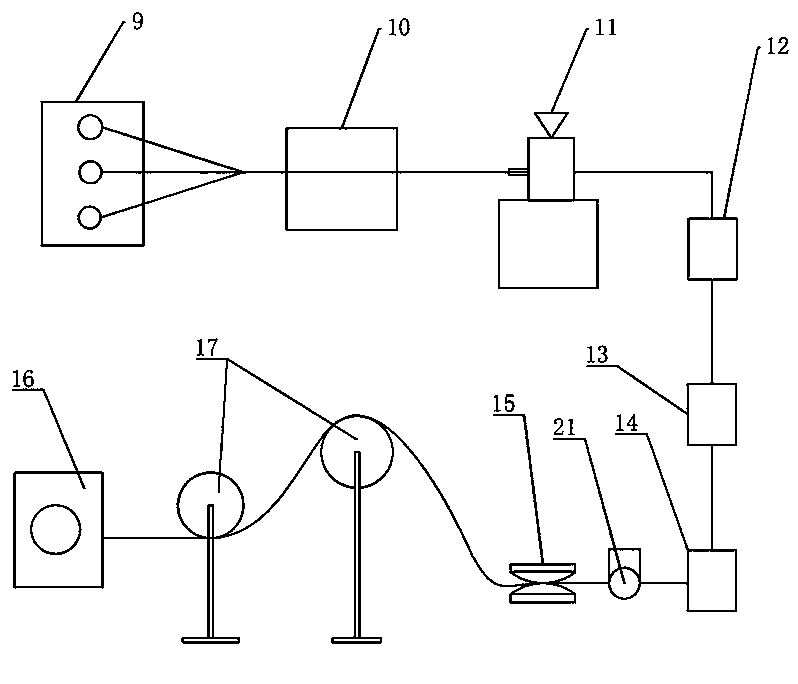

[0045] Embodiment 2, a kind of preparation technology of easy to open and strip flat optical cable, such as image 3 , including the following steps: the first step is to put the optical fiber protective sleeve 2 on the pay-off frame 9, and then the optical cable is connected to the molding table 10; the second step is to connect the extruder mold 5 to the head of the extruder 11, The plastic is plastically molded in the extruder 11; in the third step, the extrusion port of the extruder 11 is connected with a slow cooling device 21, a hot water tank 12, a warm water tank 13, a cold water tank 14, and a blow dryer 15 in sequence; Figure 4 , the fourth step is to place the transmission device 17 and the wire take-up machine 16 at the outlet of the blow dryer 15 in sequence. The flat optical cable extruded by this process can be connected to the equipment access point at one time during construction. When entering the point, the outer sheath can be torn off by hand, and the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com