PCB welding spot defect detection method

A defect detection and solder joint technology, applied in the field of image processing, can solve the problems of single feature, small number of experimental samples, single detection type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in more detail below with reference to the schematic diagram. According to the following description and claims, the advantages and features of the present invention will be clearer. It should be noted that the drawings are in a very simplified form and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

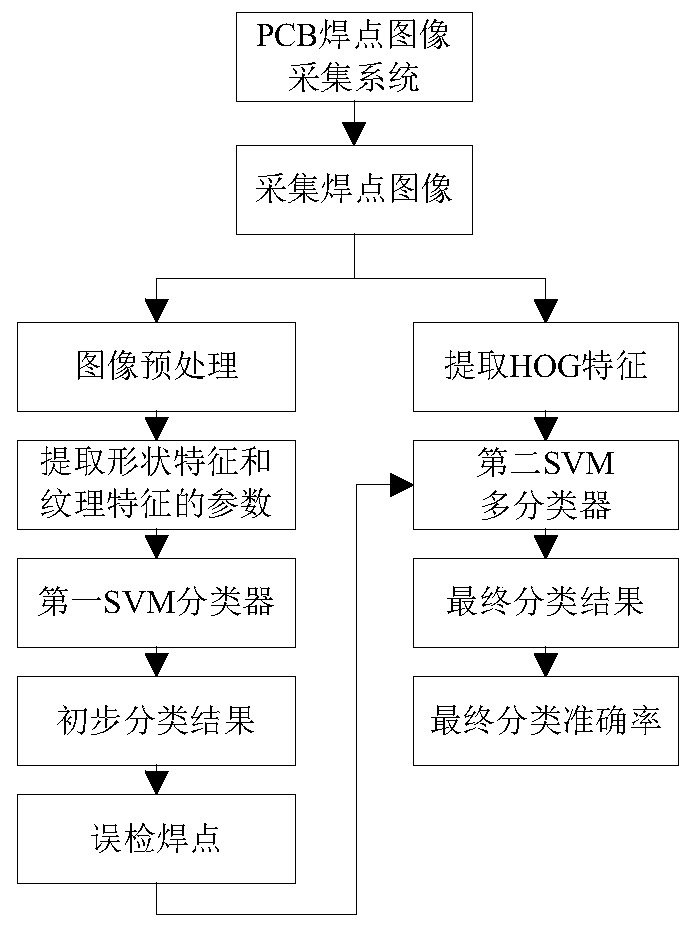

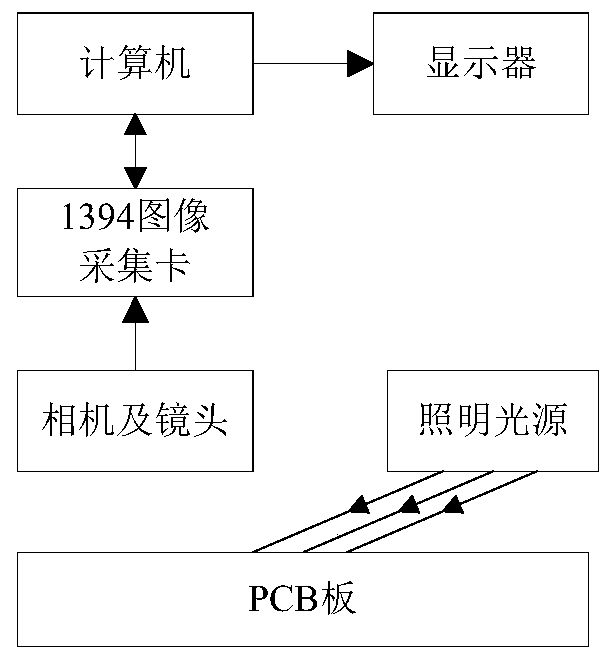

[0033] Such as figure 1 As shown, this embodiment provides a PCB solder joint defect detection method, including:

[0034] S1: Obtain multiple sets of defect feature data corresponding to PCB solder joints, and use SVM algorithm to train to obtain a first SVM classifier based on shape and texture features and a second SVM multi-classifier based on HOG features;

[0035] S2: Obtain a solder joint image of a PCB and preprocess it;

[0036] S3: Extract the shape feature parameters, texture feature parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com