Air-blowing and riveting integrated machine with detecting function

An all-in-one machine and air blowing machine technology, which is applied in the fields of riveting and pressing all-in-one machines and air blowing, can solve the problems of lack of sealing rings, cumbersome production process, and low production efficiency, so as to improve installation efficiency, maintain the same specifications and quality, and reduce labor costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

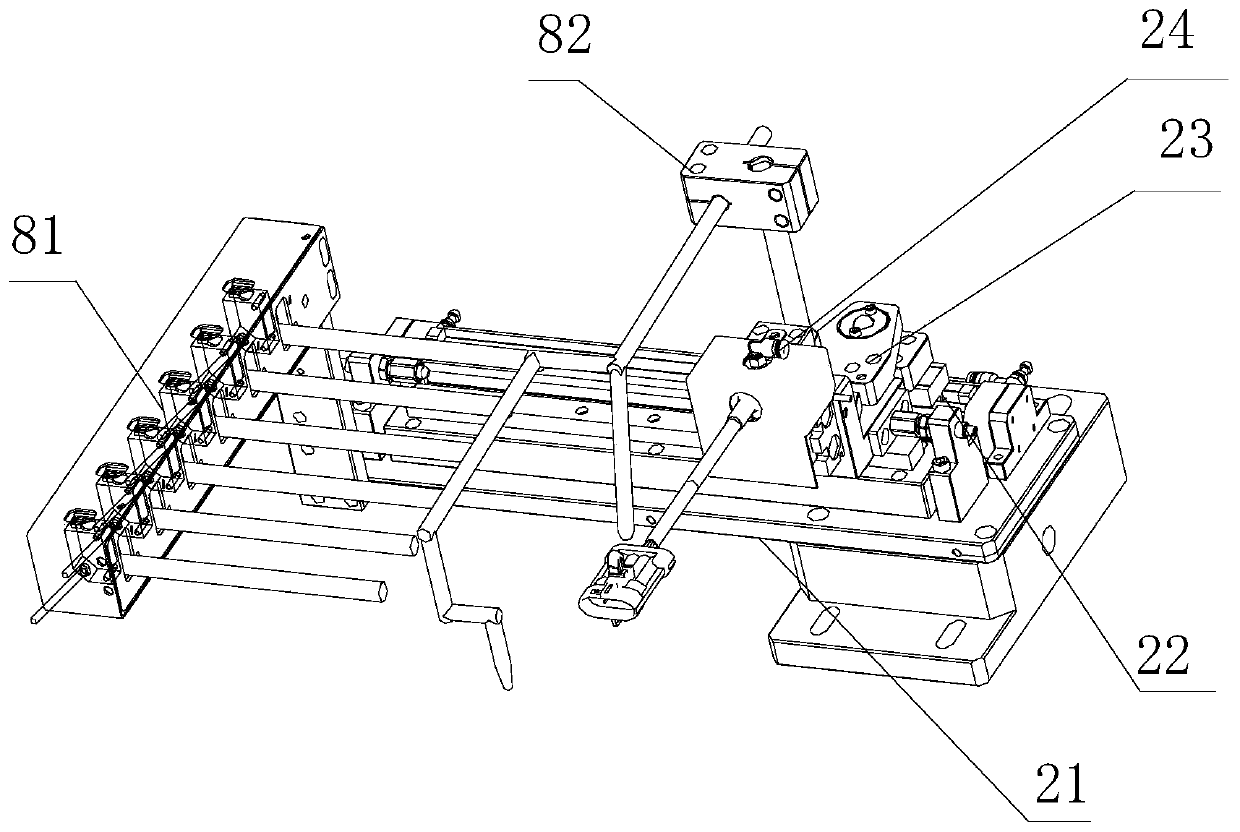

[0028] The wire harness 9 is mainly composed of an insulating sheath, a terminal, a wire and an insulating dressing material, etc., and a metal shell 91 is provided at the junction of the wire terminal and the wire harness. The riveted wire harness joint is used to connect the wire terminal and the wire. When connecting, it is necessary to rivet the metal shell 91 at the joint of the wire harness 9 on the wire harness 9 , and a sealing ring 92 is sleeved at the riveting position between the metal shell 91 and the wire harness 9 , and the wire is inserted into the sealing ring 92 .

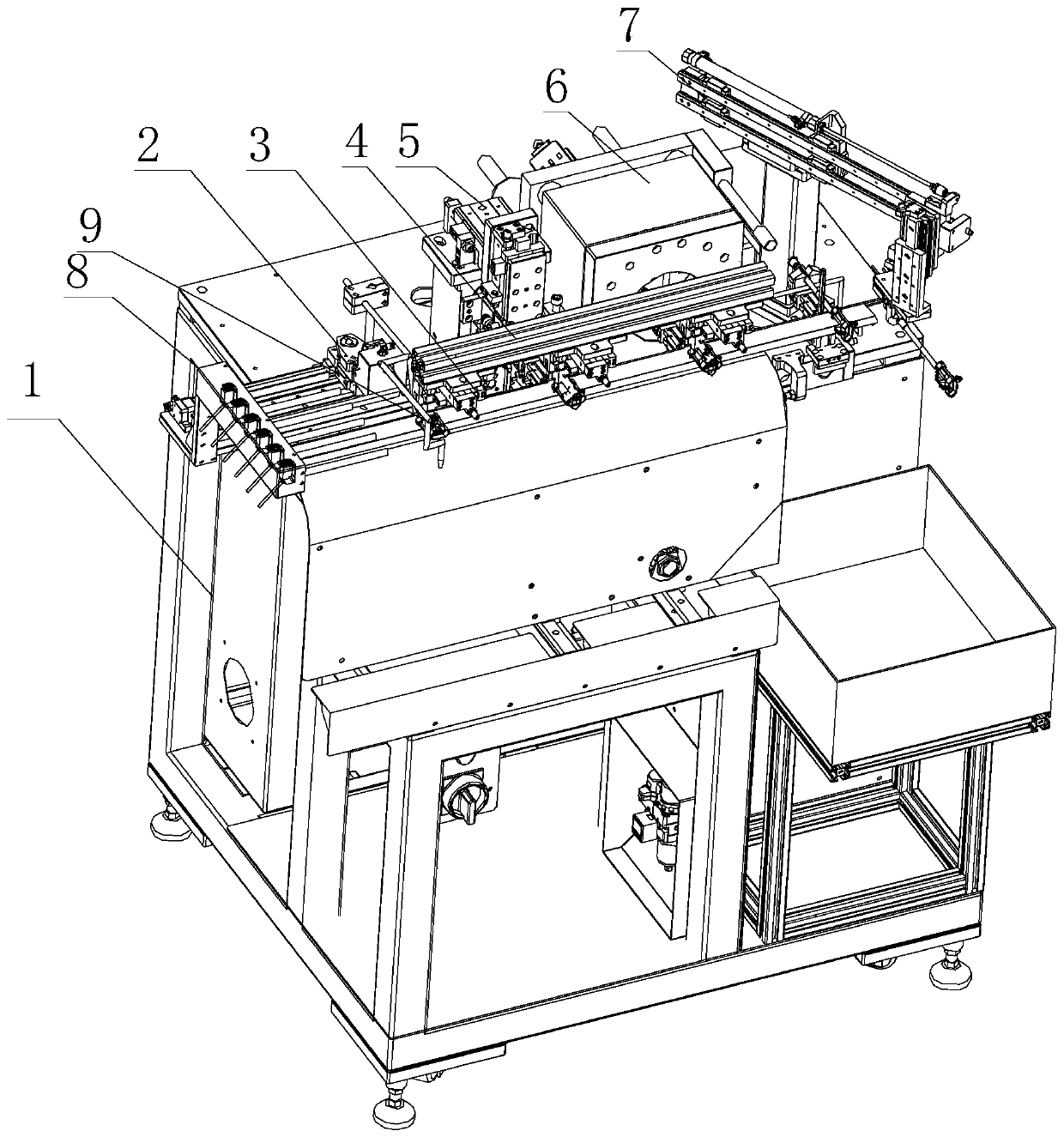

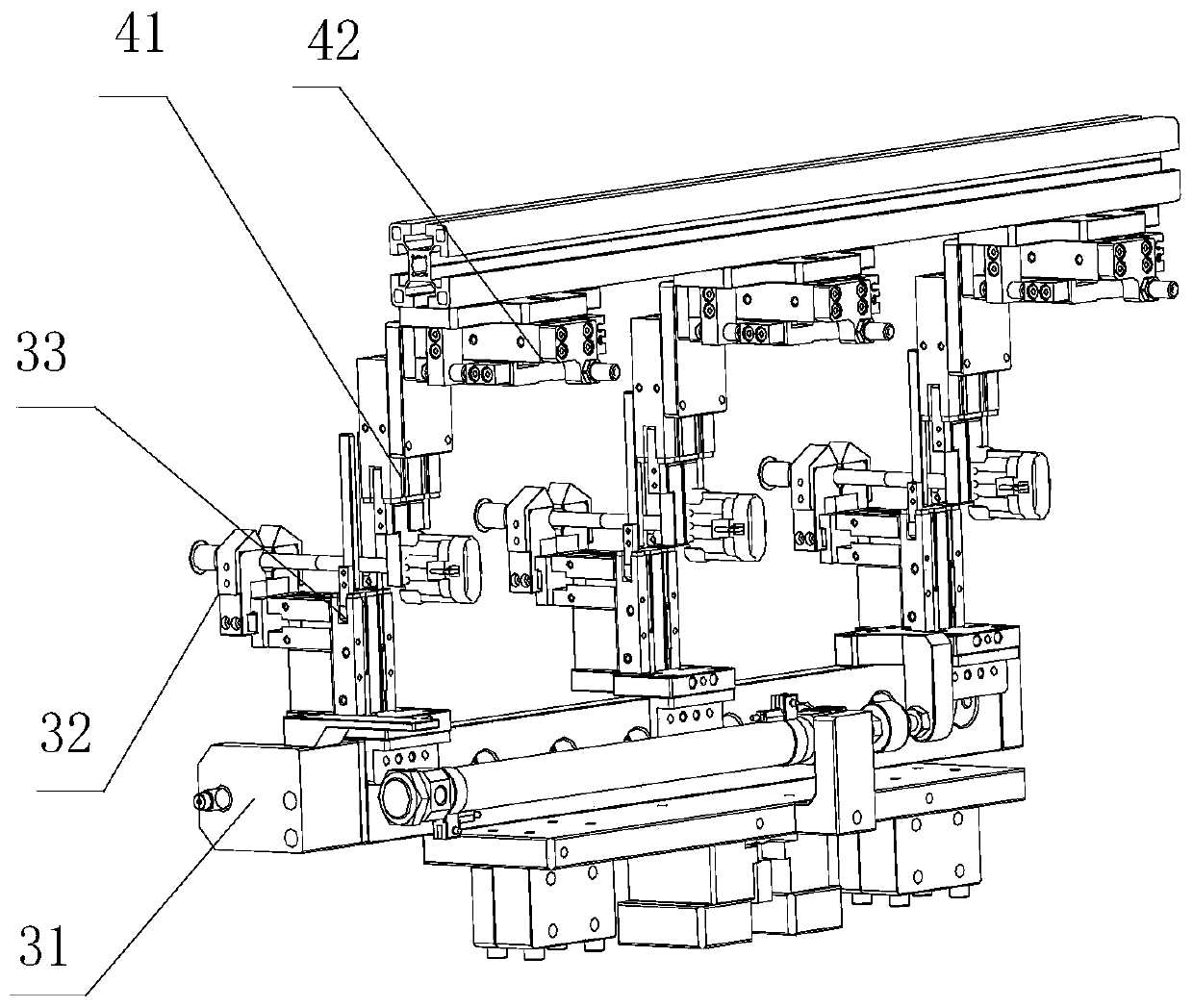

[0029] refer to figure 1 As shown, an embodiment of an air blowing and riveting integrated machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com