Pen having an integrally injection-moulded coating sleeve

A covering and injection molding technology, applied in packaging, household utensils, household packaging, etc., can solve the problem that engineering wax will not migrate undesirably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0093] For the first example, 60% by weight of SAN (LURAN 378P TM ) and 40% by weight of TPC-ET (ArnitelEM400 TM ) is adjusted to a temperature of preferably 250°C + / - 10°C and is injection moldable with the addition of 3% pigment (preferably a commercially available type of black pigment - carbon black CI 77266, which is available in different companies) Viscous state and mix evenly at the same time. No other fillers or excipients are added. For this purpose, extruders from the company Leistritz (90459 Nuremberg, Germany) can be used.

[0094] The real injection molding process can be carried out on the E-motion 940 / 160T injection molding machine of Engel Company (90451 Nuremberg, Germany). The prepared material is injected into the cavity of the injection mold with an injection pressure of about 1400 bar. The injection mold is then cooled by a liquid medium which flows through the injection mold in a sealed manner relative to the cavity. In particular, the core pin of t...

no. 2 example

[0106] To make the second example, 60% by weight of AES (ROTEC A702 TM ) and 40% by weight of TPC-ET (Arnitel EM400 TM ) is adjusted to a temperature of preferably 250° C. + / - 10° C. with the addition of 3% pigments (preferably black pigments of the above-mentioned type) and brought into an injection moldable viscous state while being mixed homogeneously. No other fillers or auxiliary materials are added.

[0107]Material processing is also carried out during the pouring process by means of the machine described there, as described above for the first exemplary embodiment.

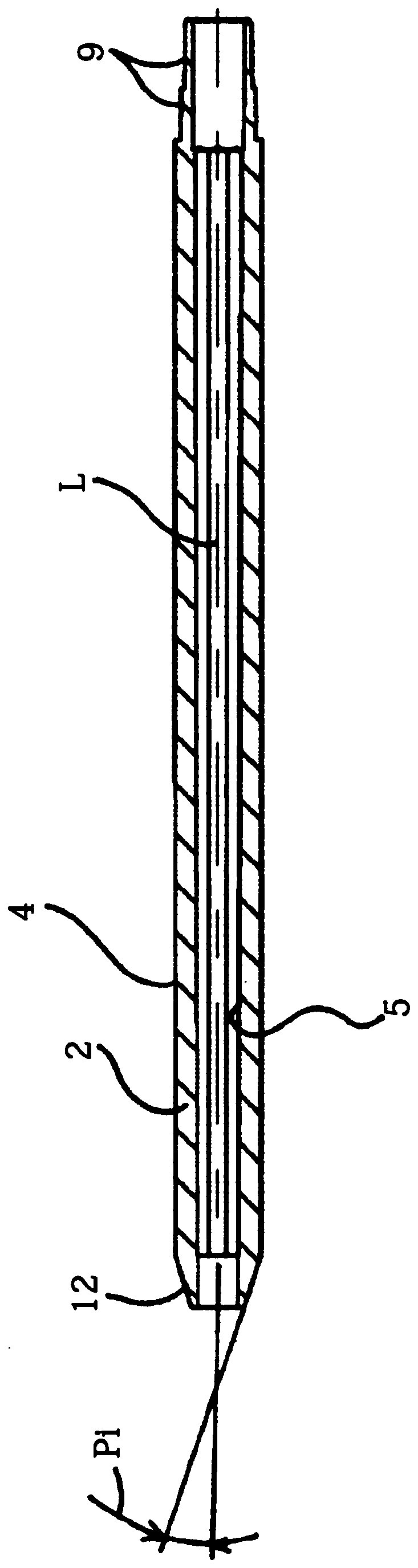

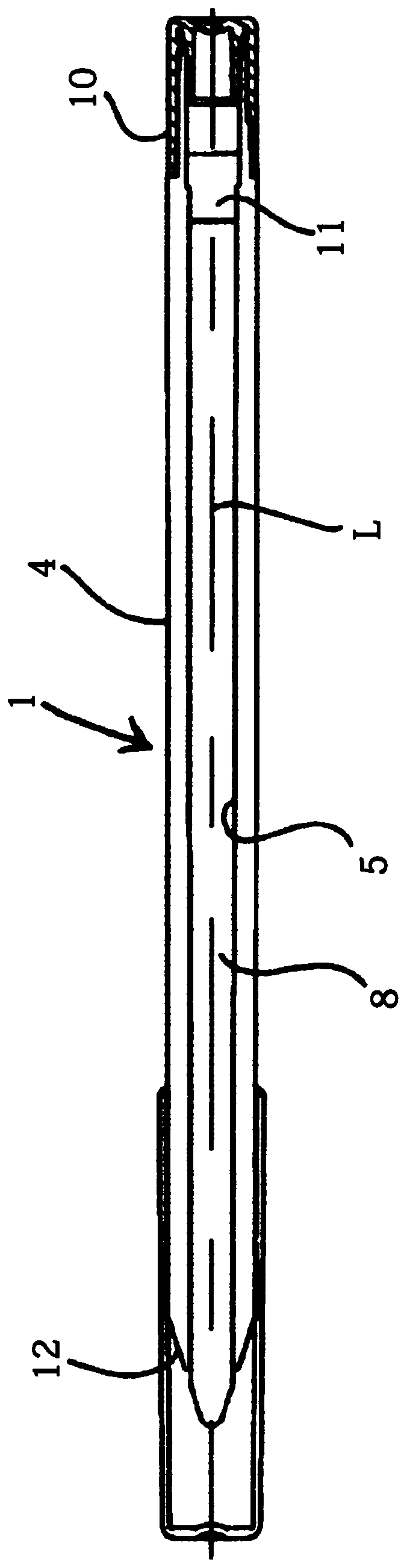

[0108] The casing 2 thus produced is particularly preferred to look as figure 1 as shown.

[0109] The cover produced in this way exhibits a remarkably scratch-resistant, satin-gloss outer peripheral surface. It is resistant to migration of refill components and decorates well.

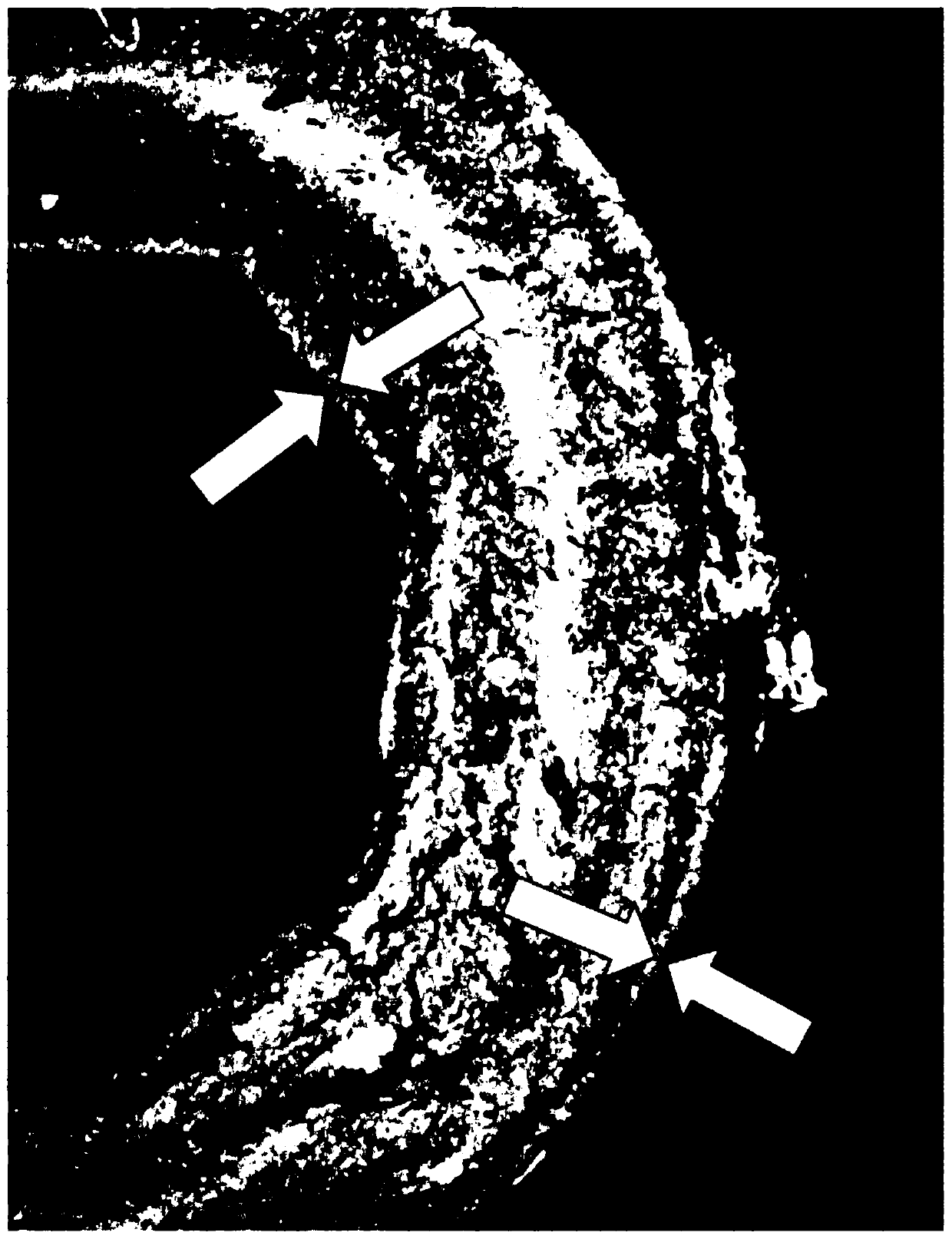

[0110] Examination with the aid of Raman spectroscopy, as described in detail below, showed that, during injection molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com