Dual clutch having a load transfer plate immersing in sections and assembly formed by the dual clutch and a flywheel

A dual clutch, clutch technology, applied in clutches, friction clutches, fluid-driven clutches, etc., to achieve the effect of increasing radial structural space requirements, uniform stress distribution, and preventing breakage or other damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

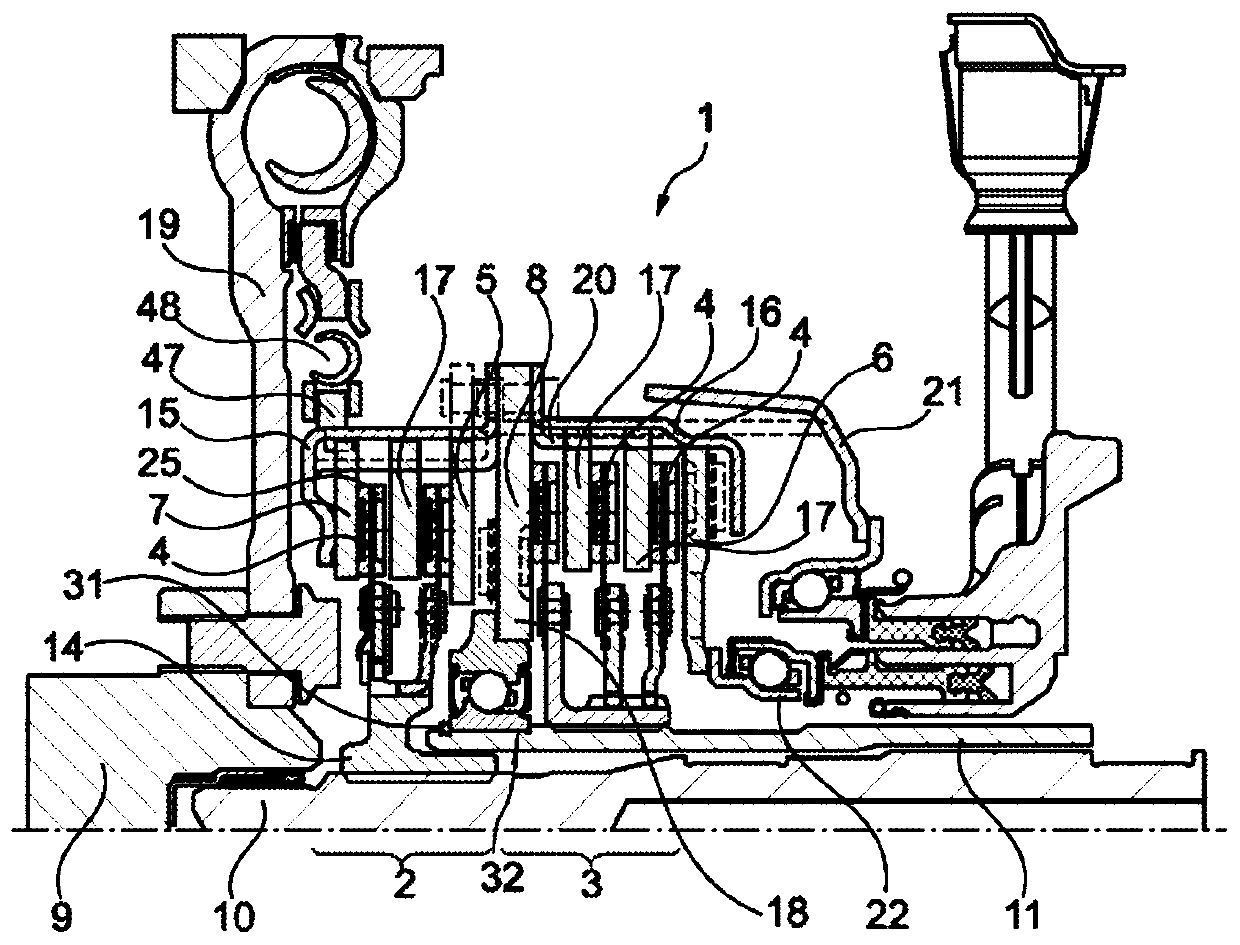

[0040] figure 1 A part of a drive train with a dual clutch 1 of a motor vehicle is shown. The dual clutch consists of a first sub-clutch 2 and a second sub-clutch 3 for selectively transmitting torque. On each individual sub-clutch 2 , 3 there is a plurality of clutch discs 4 arranged and configured to be clamped between a respective one of the pressure plates 5 , 6 and the counter pressure plates 7 , 8 for receiving the drive shaft 9 The torque is transmitted to the transmission input shafts 10, 11.

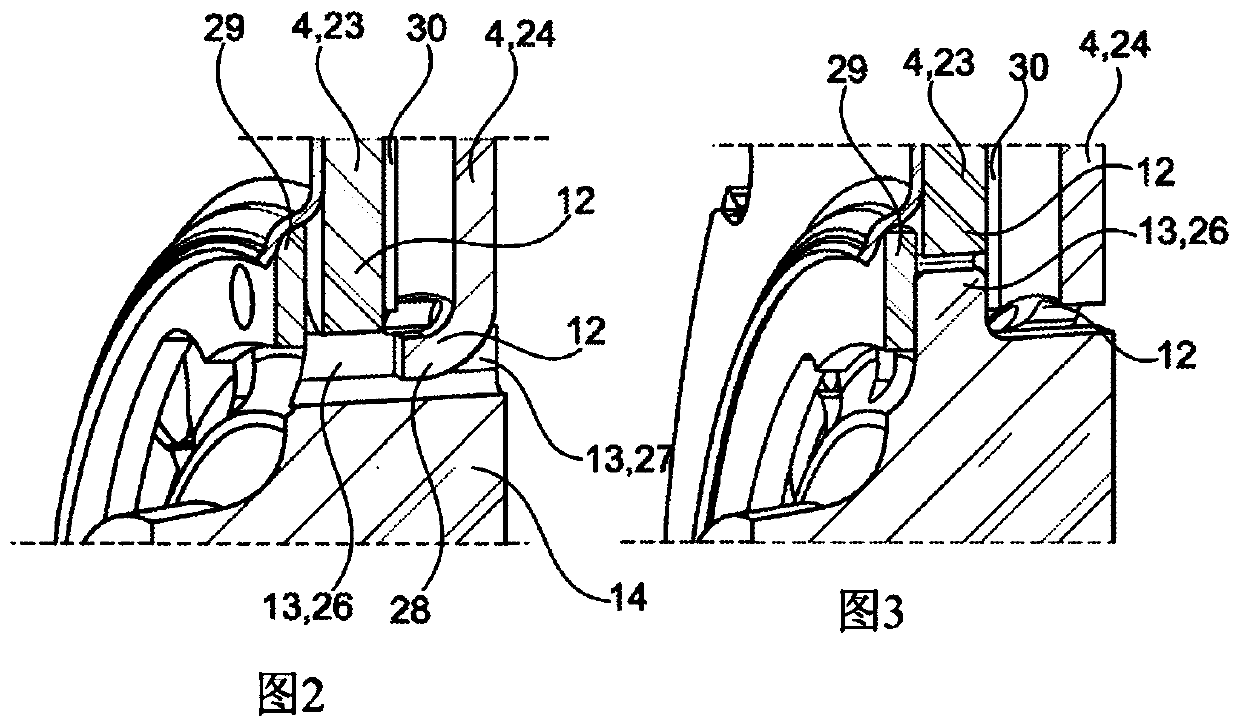

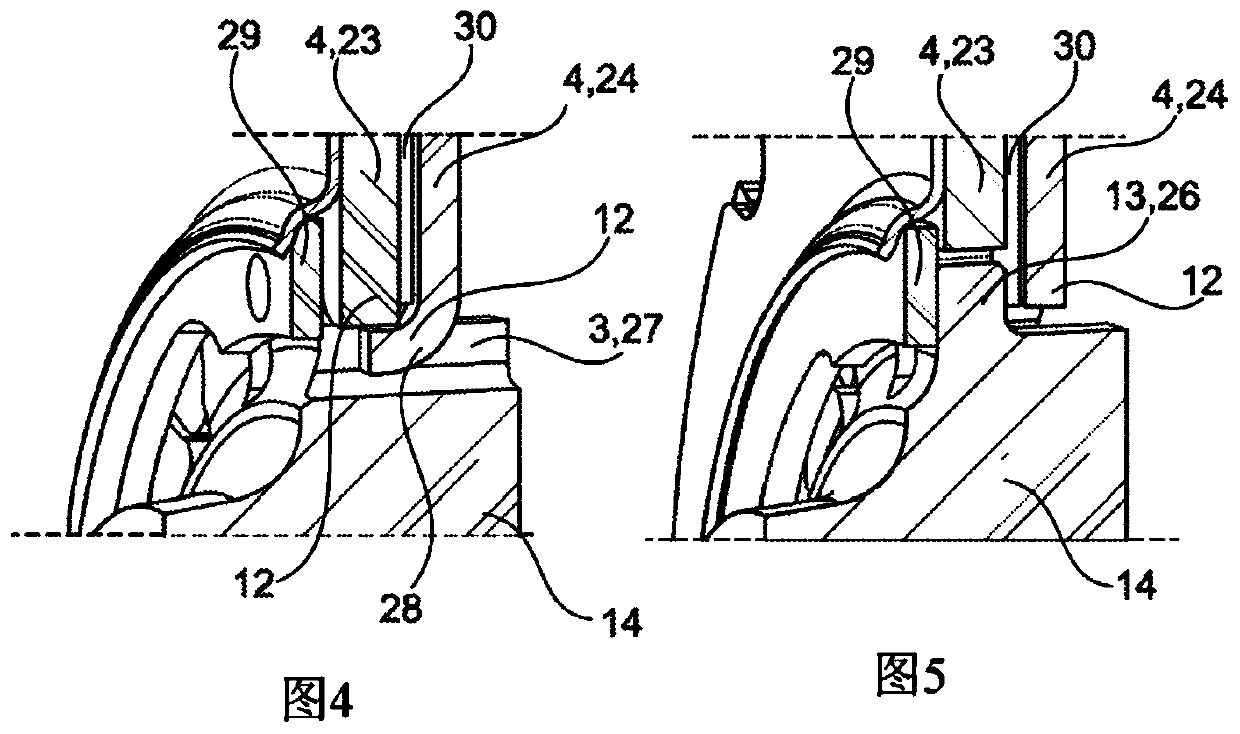

[0041] In this case, each clutch disk 4 has an inner toothing 12 , via which the clutch disk 4 cooperates with the outer toothing 13 of the clutch hub 14 . The first sub-clutch 2 and the second sub-clutch 3 each have friction lining carriers 15 , 16 which are designed to receive pressure plates 5 , 6 and counter pressure plates 7 , 8 in a rotationally locked and axially displaceable manner. and the intermediate plate 17 . The two friction plate carriers 15 , 16 of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com