Gas-liquid synchronous mixing and puffing device and ice cream machine comprising same

A puffing device, gas-liquid technology, applied in the direction of frozen desserts, food science, application, etc., can solve the problems of low puffing rate, difficult puffing rate, poor mixing effect, etc., and achieve the effect of uniform puffing and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

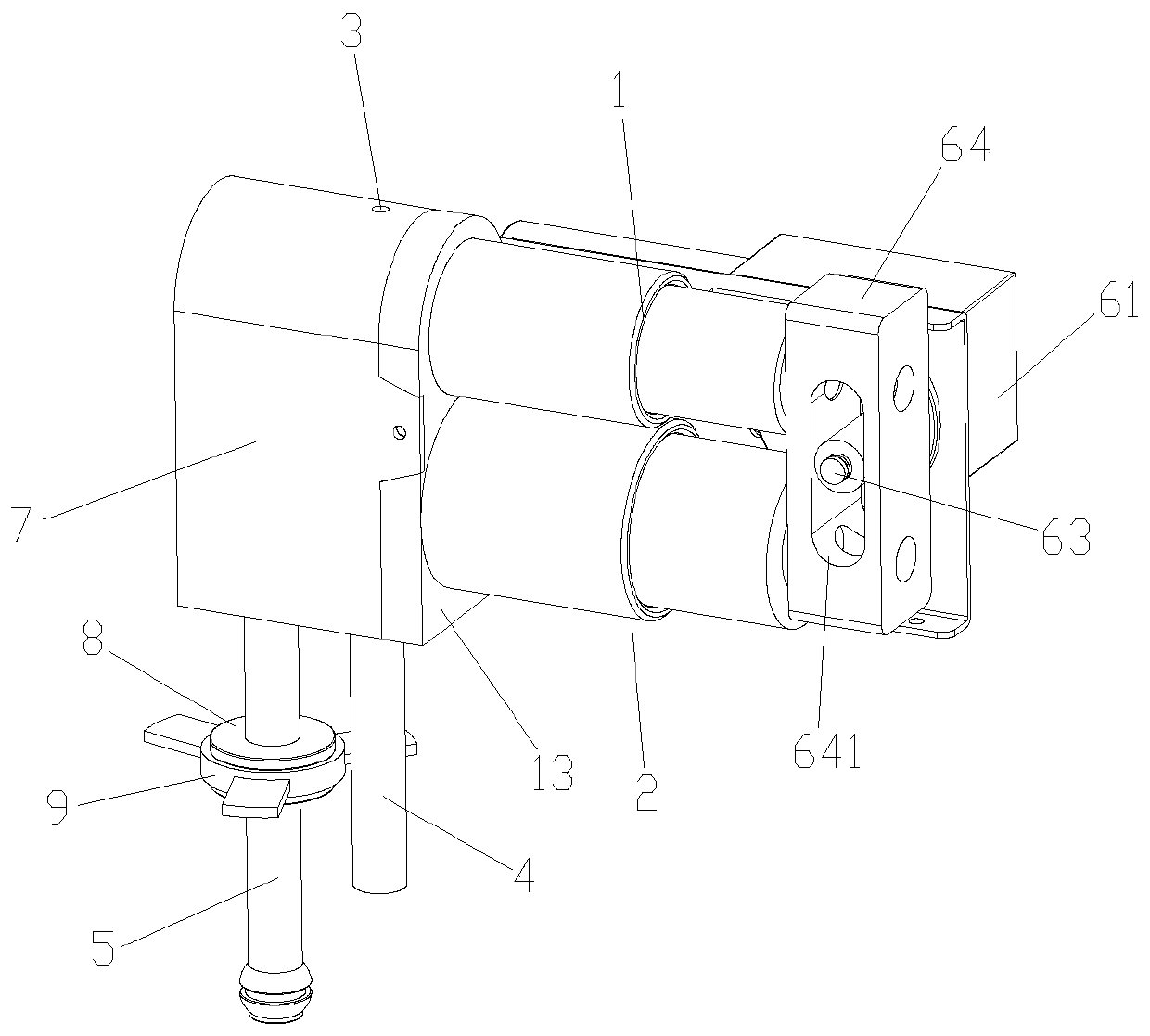

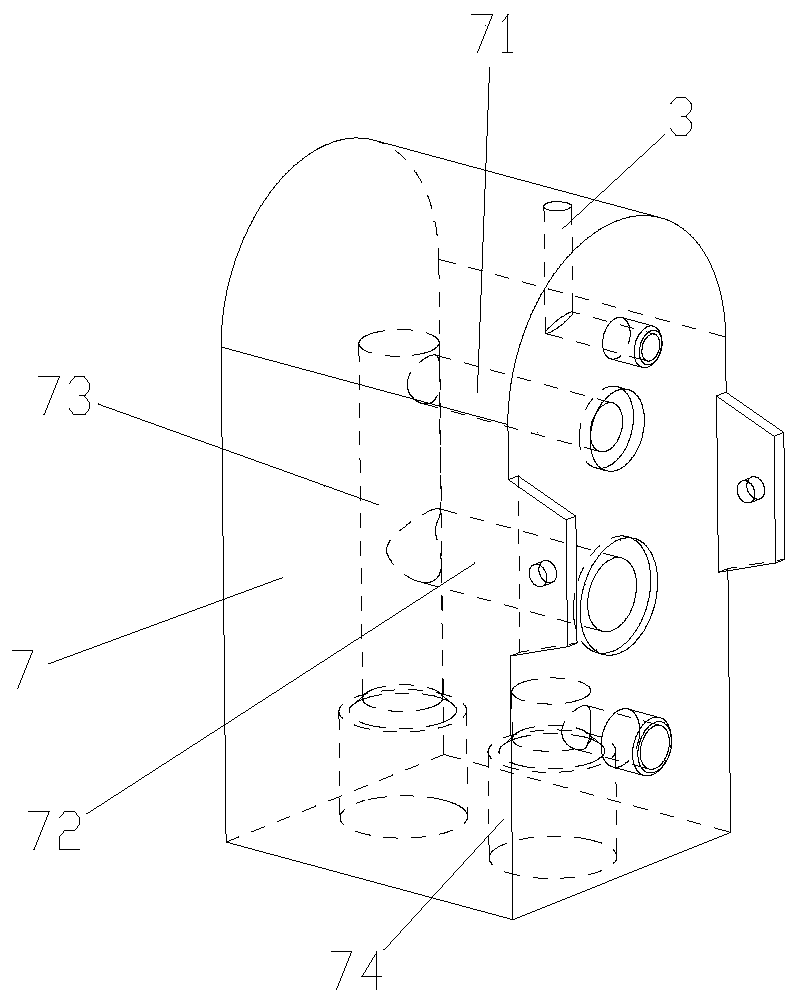

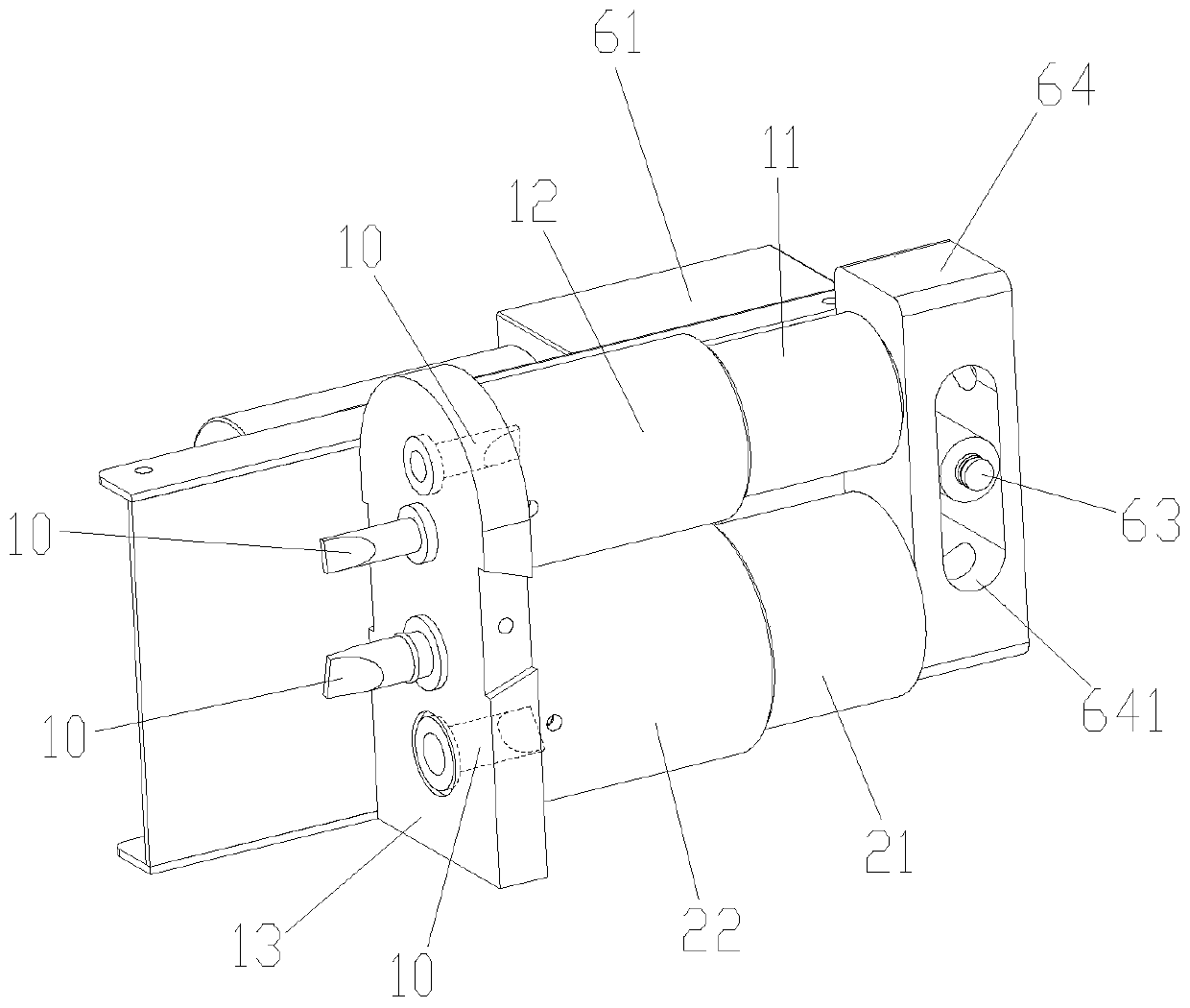

[0027] Figure 1 to Figure 8 It schematically shows the structure of a gas-liquid synchronous mixing and expanding device according to an embodiment of the present invention.

[0028] Such as Figure 1 to Figure 8 As shown, the gas-liquid synchronous mixing and puffing device includes a piston cylinder A1, a piston cylinder B2, an air intake passage 3, a feed pipe 4, a discharge pipe 5, a driving device and a one-way valve 10. In addition, the gas-liquid synchronous mixing and expanding device may further include a connecting block 7 , a pressure relief member 8 , a pressure relief ring 9 and a fixing plate 13 .

[0029] Such as figure 1 and image 3 As shown, the left end of the piston cylinder A1 (i.e. the cylinder body A12) and the left end of the piston cylinder B2 (i.e. the cylinder body B22) are all installed on one side of the fixed plate 13, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com