Full-automatic coating device

A fully automatic, coating technology, applied in spraying devices, spray booths, etc., can solve problems such as manual operation of coating uniformity, and achieve the effect of small manual labor, high efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

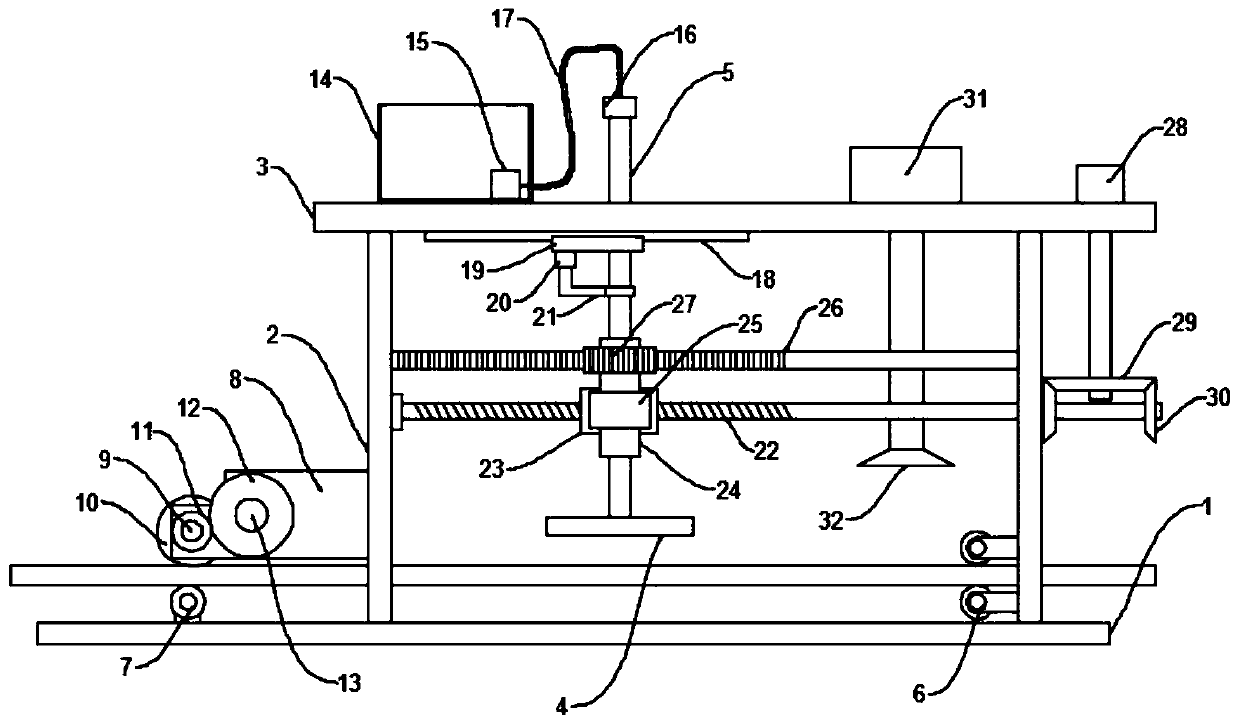

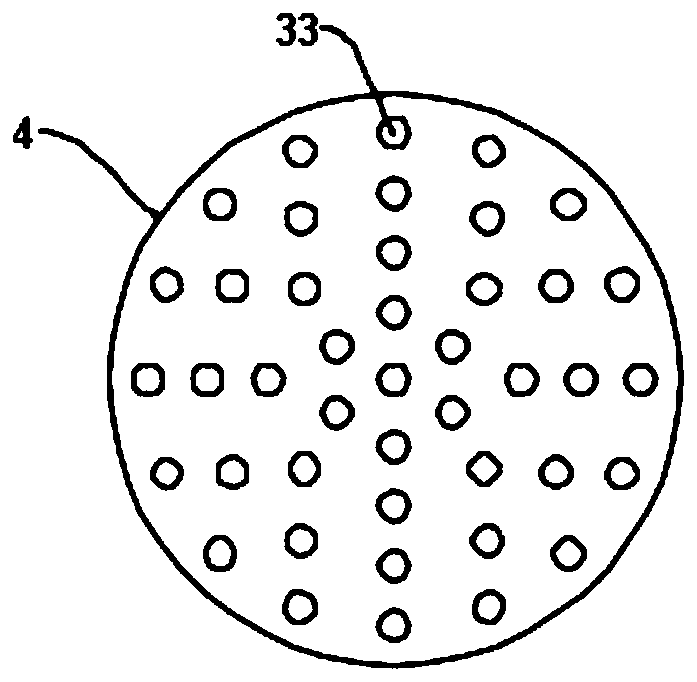

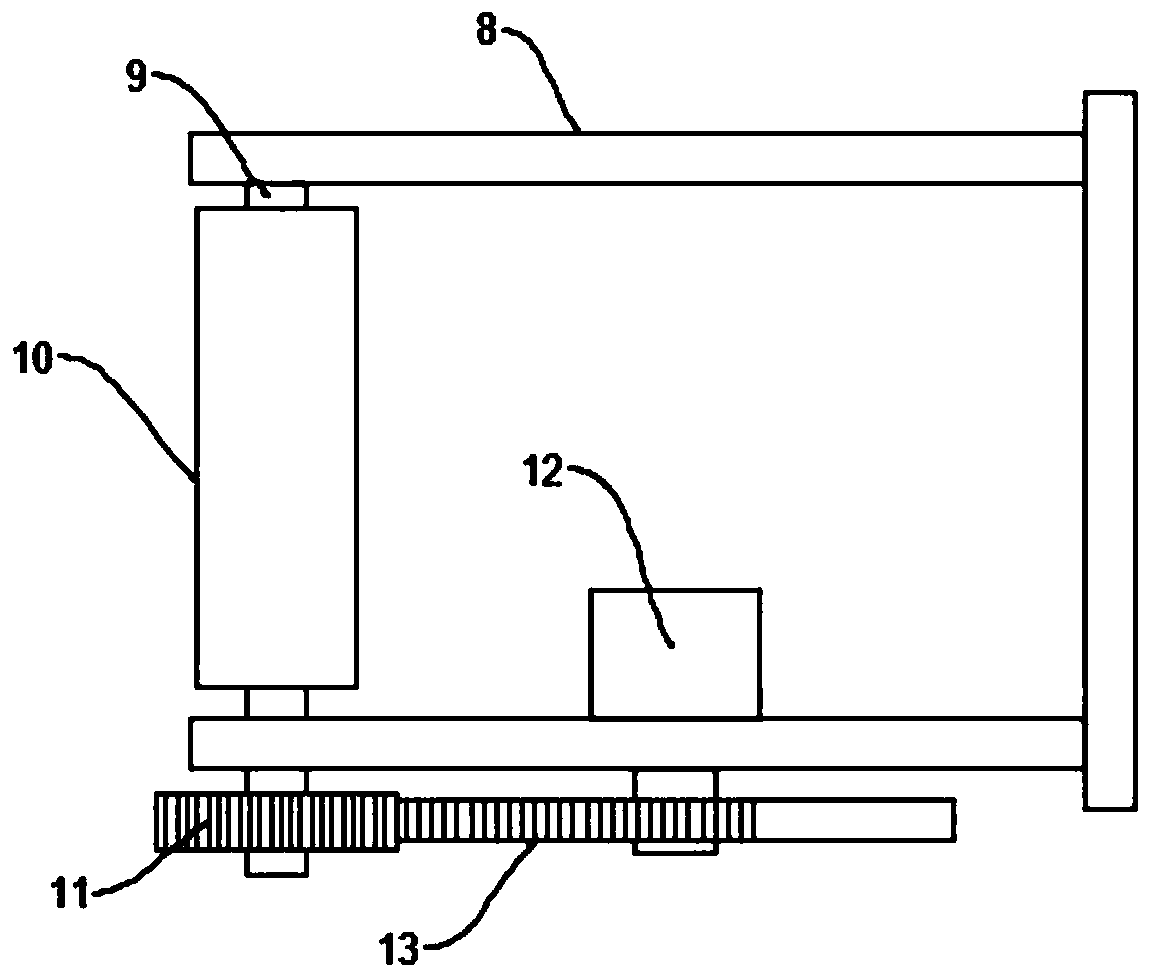

[0026] see Figure 1~3 , in an embodiment of the present invention, a fully automatic coating device, comprising a base substrate 1, a coating mechanism, and a mounting frame for installing the coating mechanism, the mounting frame includes a top plate 3 and supporting side rod frames arranged at both ends of the top plate 3 2. The lower end of the supporting side rod frame 2 is fixed on the upper surface of the base substrate 1, and the coating mechanism includes a hollow coating pan 4, a rotating suspension rod 5 for suspending the hollow coating pan 4, and a coating liquid tank 14. A plurality of evenly distributed paint penetration holes 33 are opened on the lower end surface of the smearing plate 4, and the rotating suspension rod 5 is installed on the mounting frame through a drive traverse assembly, and the drive traverse assembly includes The driving screw 22 between the rod holders 2, the driving screw 22 is provided with a spiral sleeve 23 matched therewith, the side...

Embodiment 2

[0031] see Figure 1~3 , in an embodiment of the present invention, a fully automatic coating device, comprising a base substrate 1, a coating mechanism, and a mounting frame for installing the coating mechanism, the mounting frame includes a top plate 3 and supporting side rod frames arranged at both ends of the top plate 3 2. The lower end of the supporting side rod frame 2 is fixed on the upper surface of the base substrate 1, and the coating mechanism includes a hollow coating pan 4, a rotating suspension rod 5 for suspending the hollow coating pan 4, and a coating liquid tank 14. A plurality of evenly distributed paint penetration holes 33 are opened on the lower end surface of the smearing plate 4, and the rotating suspension rod 5 is installed on the mounting frame through a drive traverse assembly, and the drive traverse assembly includes The driving screw 22 between the rod holders 2, the driving screw 22 is provided with a spiral sleeve 23 matched therewith, the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com