Umbrella-shaped distributed ornithopter

A flapping aircraft and a technology for an aircraft, applied in the field of aircraft, can solve problems such as small load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

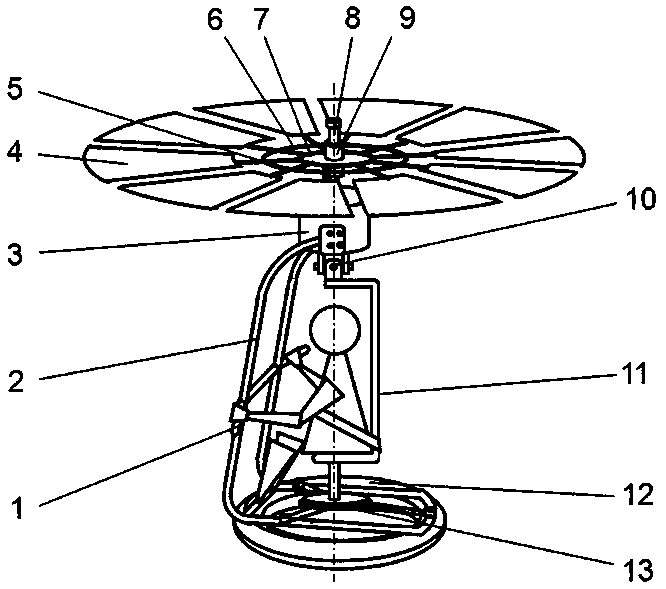

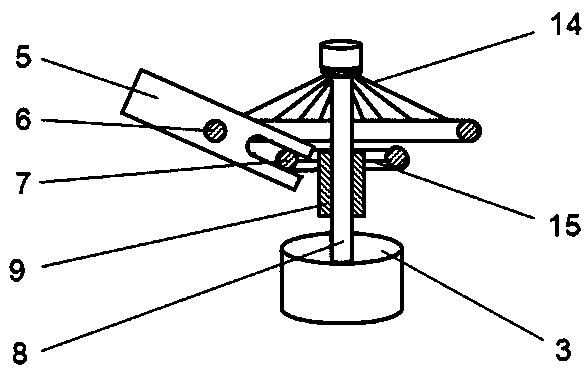

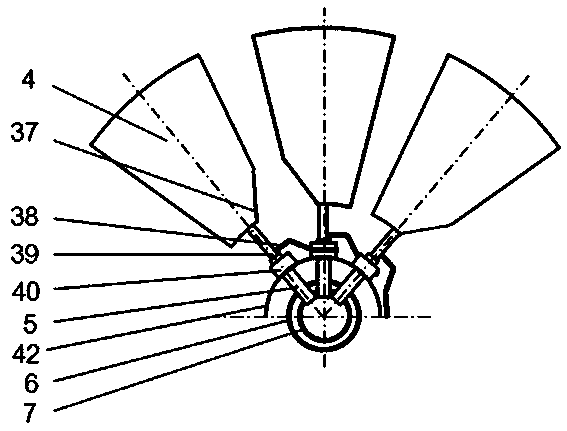

[0019] figure 1 , figure 2 Shown is the embodiment that the wing swings up and down, the frame 2 is fixedly connected with the mechanical cabin 3, the central axis 8 is fixedly connected with the mechanical cabin 3, the static ring 6 is fixedly connected with the central axis 8 through the spokes 14, and the moving ring 7 is fixedly connected with the central axis 8 through the spokes. 15 is fixedly connected with the slip ring 9 that can slide axially along the central axis 8, the wing 4 is connected with the swing rod 5 and is radially distributed with the central axis 8 as the center, the swing rod 5 is connected with the static ring 6 in rotation and connected with the dynamic The ring 7 is rotatably connected and can slide longitudinally. When the slip ring 9 slides up and down along the central axis 8, it can drive the wing 4 to swing up and down to generate thrust; the types of the wing 4 include but are not limited to thin shell type, one-way air hole type , inverted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com