A kind of high temperature resistant UV polymerized body foam damping material and preparation method thereof

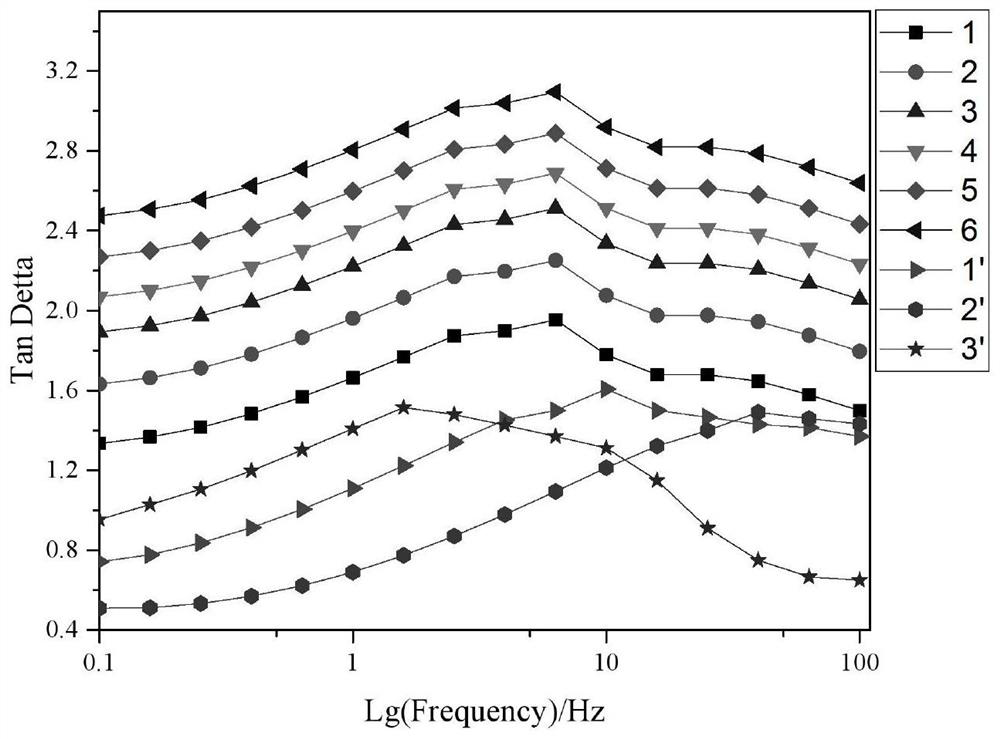

A technology of body foaming and damping materials, applied in the field of damping materials, can solve the problems of comprehensive performance and service life of materials, cumbersome and complicated process technology routes, and low temperature of damping materials, etc., to achieve good energy absorption capacity and good flexibility , the effect of low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

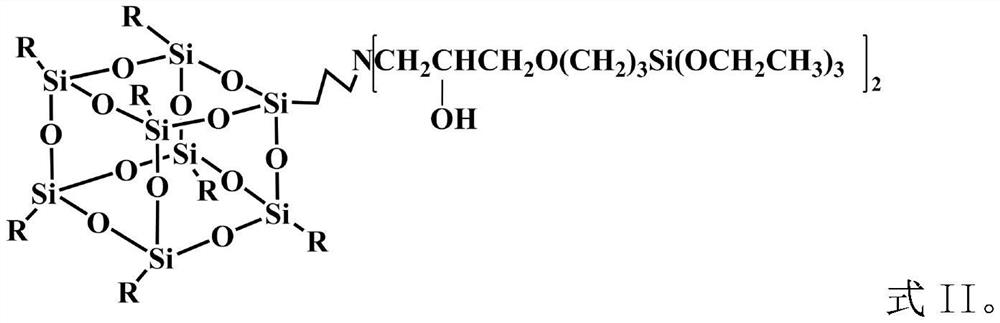

[0038] The present invention also provides a method for preparing a high temperature resistant UV polymerization type body foam damping material, which comprises the following steps:

[0039] 1) Add POSS, acrylate copolymer, reactive diluent and photoinitiator to the reaction kettle, and continuously stir and swell at room temperature to form a uniform UV polymerized bulk foam damping material composition;

[0040] 2) Apply the UV polymerizable body foam damping material composition obtained in step 1) evenly on the release PET film, and irradiate it under ultraviolet light for 3-6 minutes to obtain the UV polymerizable body foam damping material .

Embodiment 1

[0042] A kind of preparation method of UV polymerization type bulk foam damping material, it comprises the following steps:

[0043] 1) Take each component by the following parts by weight:

[0044] Acrylate copolymer: 25 parts;

[0045] Active diluent: 69.5 parts;

[0046] Photoinitiator: 0.5 part;

[0047] POSS: 5 copies;

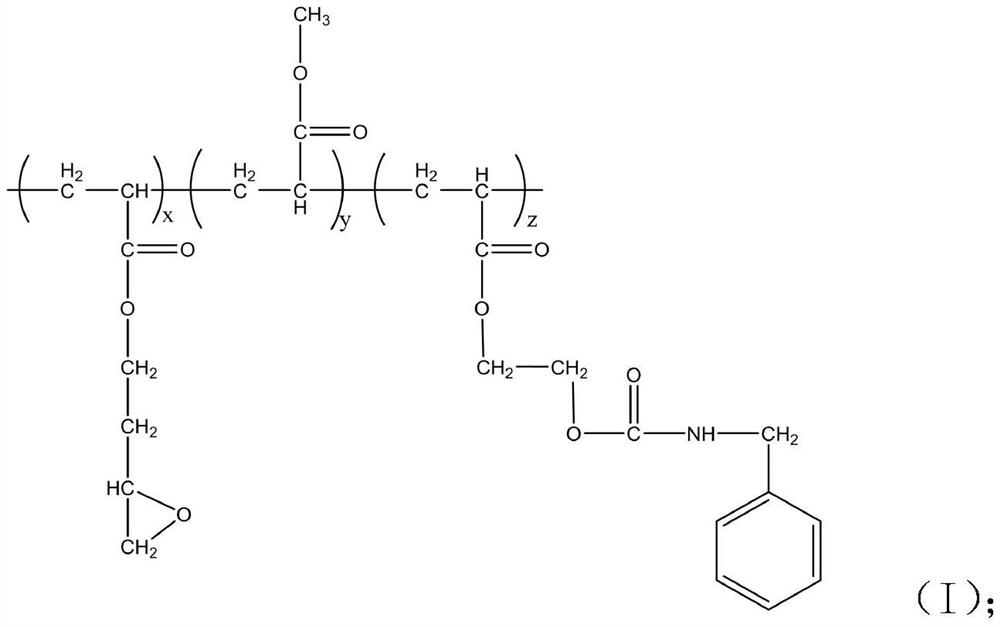

[0048] Described acrylate copolymer is the copolymer of epoxy acrylate and polyurethane acrylate, and its structure is as shown in formula (I):

[0049]

[0050] Wherein, the reactive diluent is a mixture of isooctyl acrylate and vinyl acetate in a mass ratio of 2:1, and the photoinitiator is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide.

[0051] 2) Add POSS, acrylate copolymer, reactive diluent and photoinitiator to the reaction kettle, and continuously stir and swell at room temperature to form a uniform UV polymerized bulk foam damping material composition;

[0052] 3) Uniformly coat the UV polymerization type body foaming damping material co...

Embodiment 2

[0054] A kind of preparation method of UV polymerization type bulk foam damping material, it comprises the following steps:

[0055] 1) Take each component by the following parts by weight:

[0056] Acrylate copolymer: 30 parts;

[0057] Active diluent: 63.4 parts;

[0058] Photoinitiator: 0.6 part;

[0059] POSS: 6 copies;

[0060] Described linear acrylate copolymer is the copolymer of epoxy acrylate and polyurethane acrylate, and its structure is as shown in formula (I):

[0061]

[0062] Wherein, the reactive diluent is a mixture of styrene and vinyl acetate in a mass ratio of 2:1, and the photoinitiator is benzoylformate.

[0063] 2) Add POSS, acrylate copolymer, reactive diluent and photoinitiator to the reaction kettle, and continuously stir and swell at room temperature to form a uniform UV polymerized bulk foam damping material composition;

[0064] 3) Uniformly coat the UV polymerization type body foaming damping material composition obtained in step 2) on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Damping temperature range | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com