Fast-insertion wear alarm mechanism and assembly method thereof

An alarm line and wear block technology, applied in mechanical equipment, brake types, etc., can solve the problems of limited installation space of alarm mechanisms, increased cost of alarm mechanisms, and increased alarm mechanisms, and achieves compact structure, simple structure, and reduced replacement and maintenance. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The assembly method using the quick-insert wear alarm mechanism of Embodiment 1 includes the following steps:

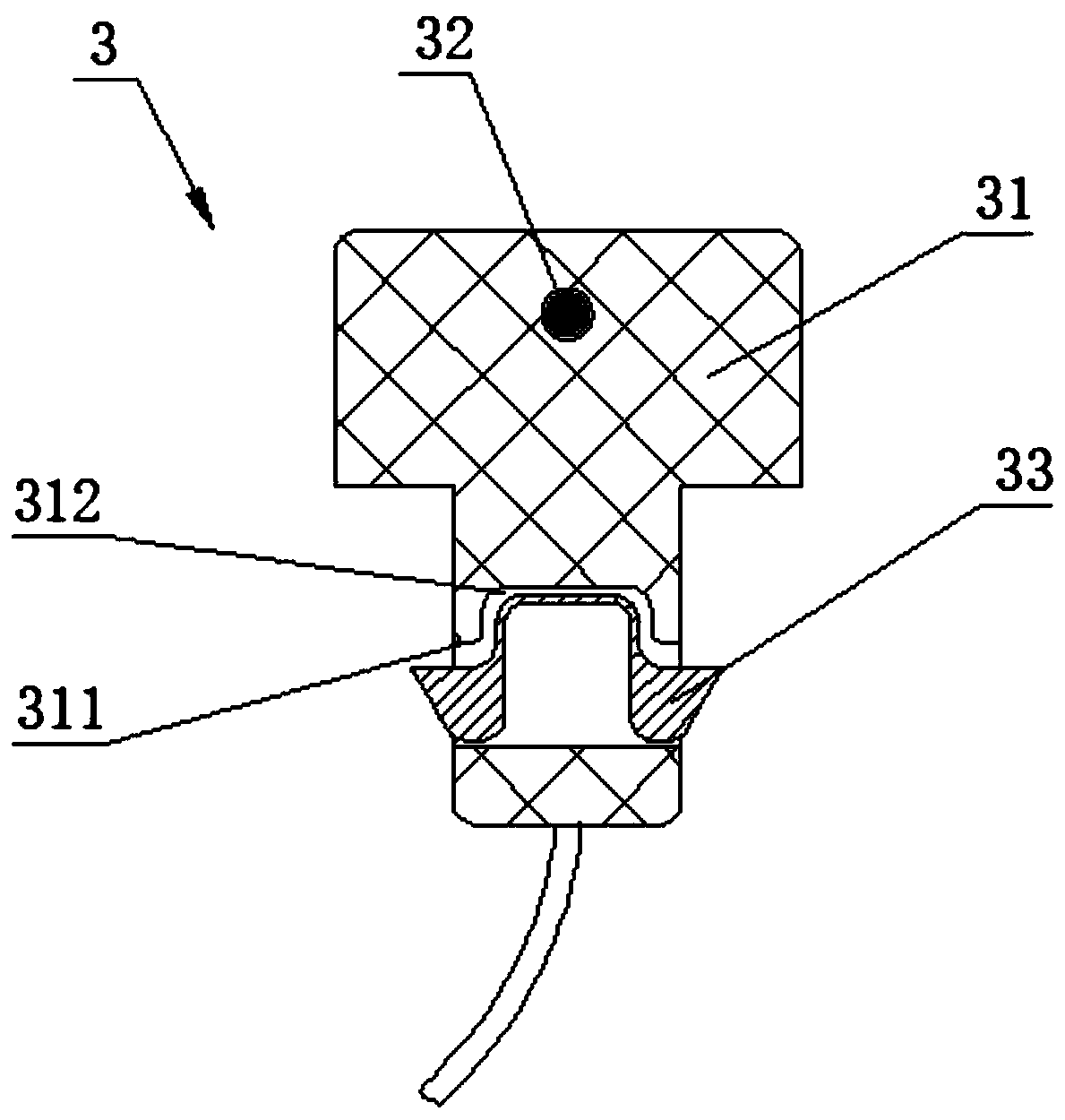

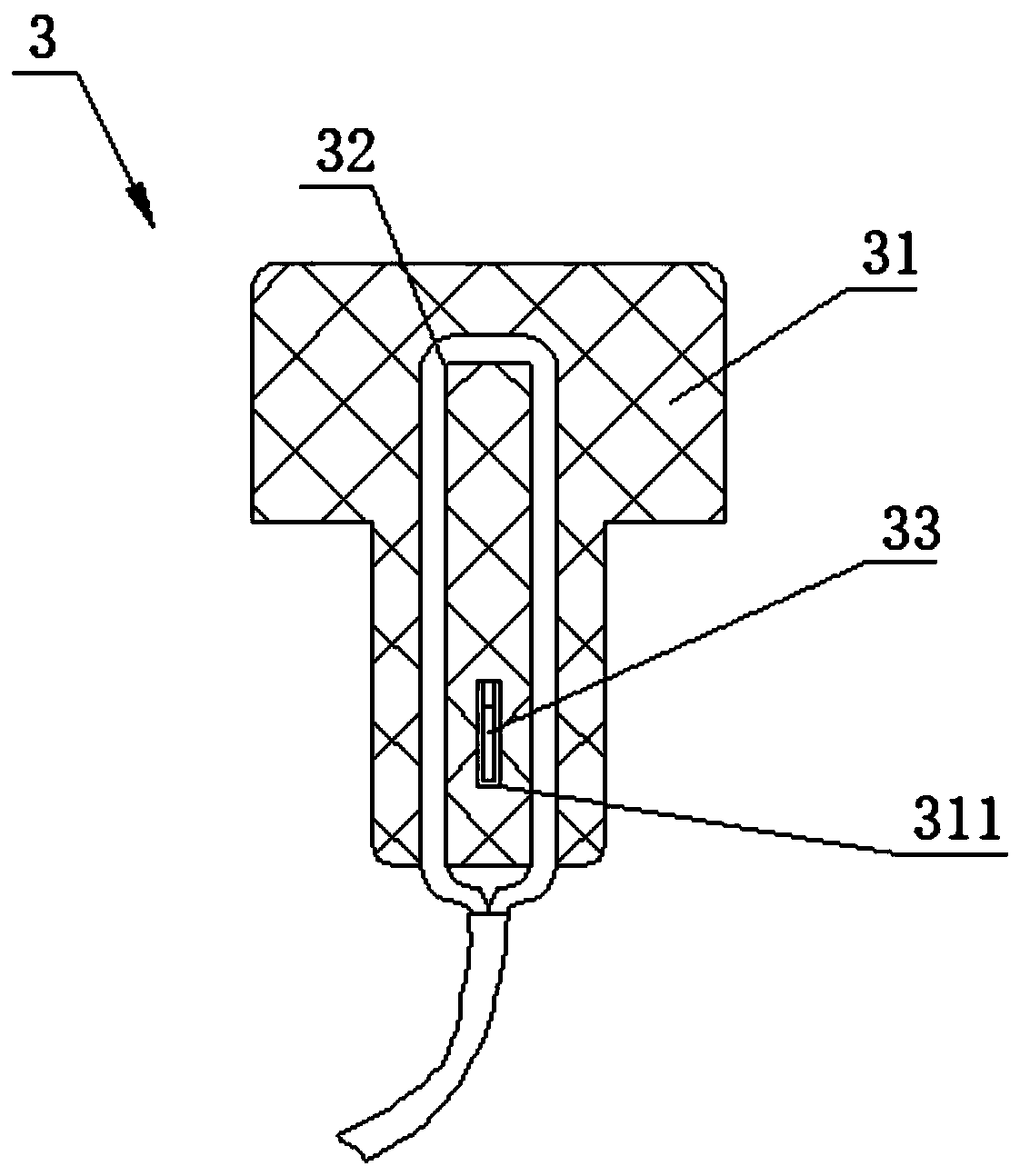

[0042] The first step: prepare materials, prepare the total cost body 31, the wiring harness 32, and the elastic card 33;

[0043] Step 2: Assemble the alarm wire assembly 3, run the wiring harness 32 through the main body 31, and make both ends pass through the bottom of the main body 31; flatten the U-shaped body 332 of the elastic card 33 and quickly put one end The hook 331 extends into the through hole 311 and passes through the assembly body 31. The flattened U-shaped body 332 is released inside the assembly body 31 and restored to its original shape to be contained in the groove 312, so that the elastic clip 33 is clamped on the assembly On the body 31; the assembly of the alarm line assembly 3 is completed;

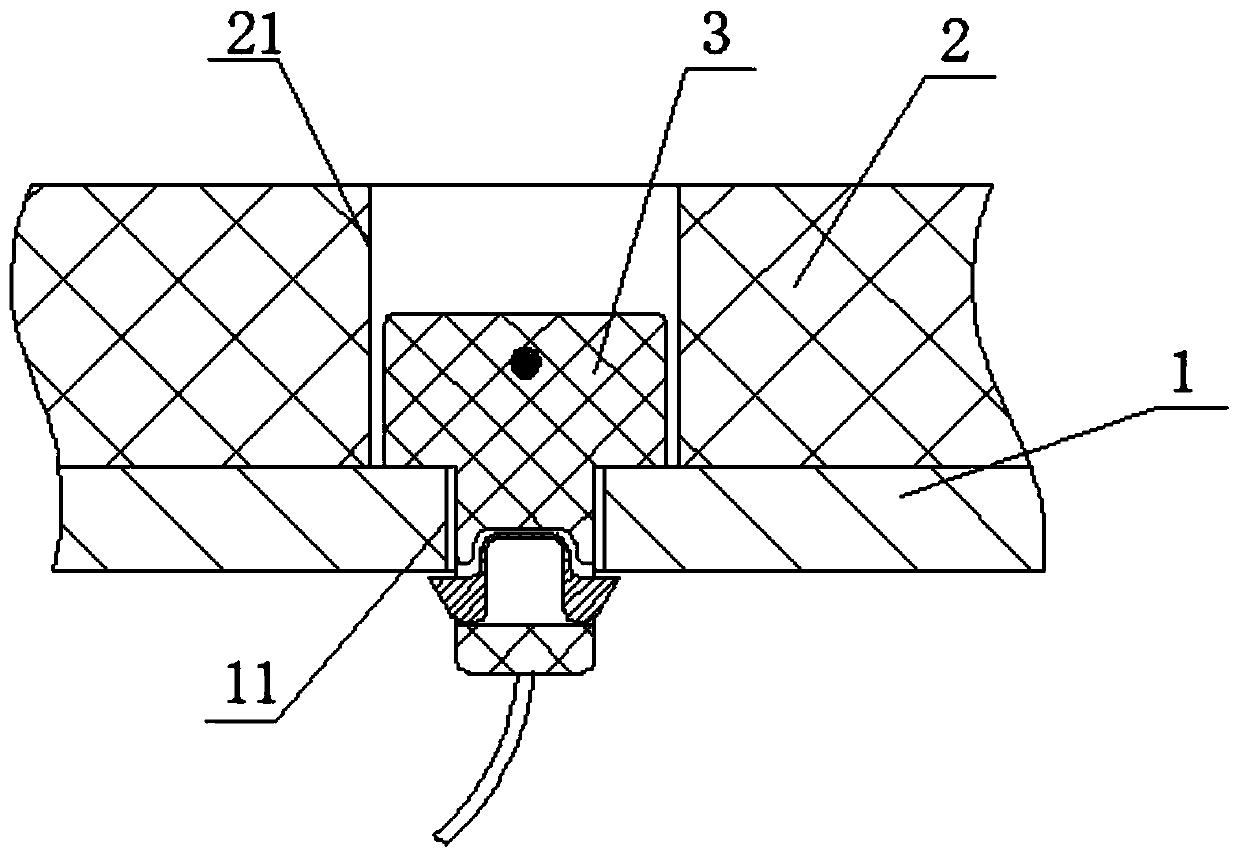

[0044]The third step: install the alarm wire assembly 3, put the alarm wire assembly 3 into the through hole 1 from the end of the brake lining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com