Treatment method for preventing expansion and cracking of boiler

An anti-expansion and boiler technology, which is applied in the field of expansion and cracking of boilers, can solve problems such as boiler tube burst, and achieve the effects of increasing service life, reducing impact and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

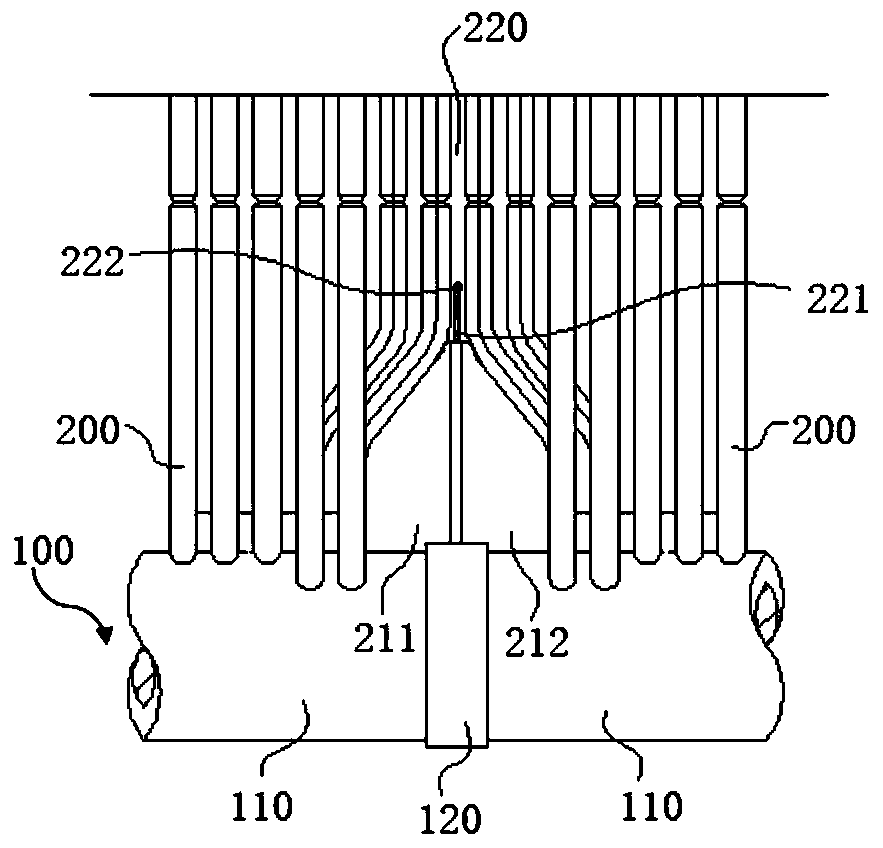

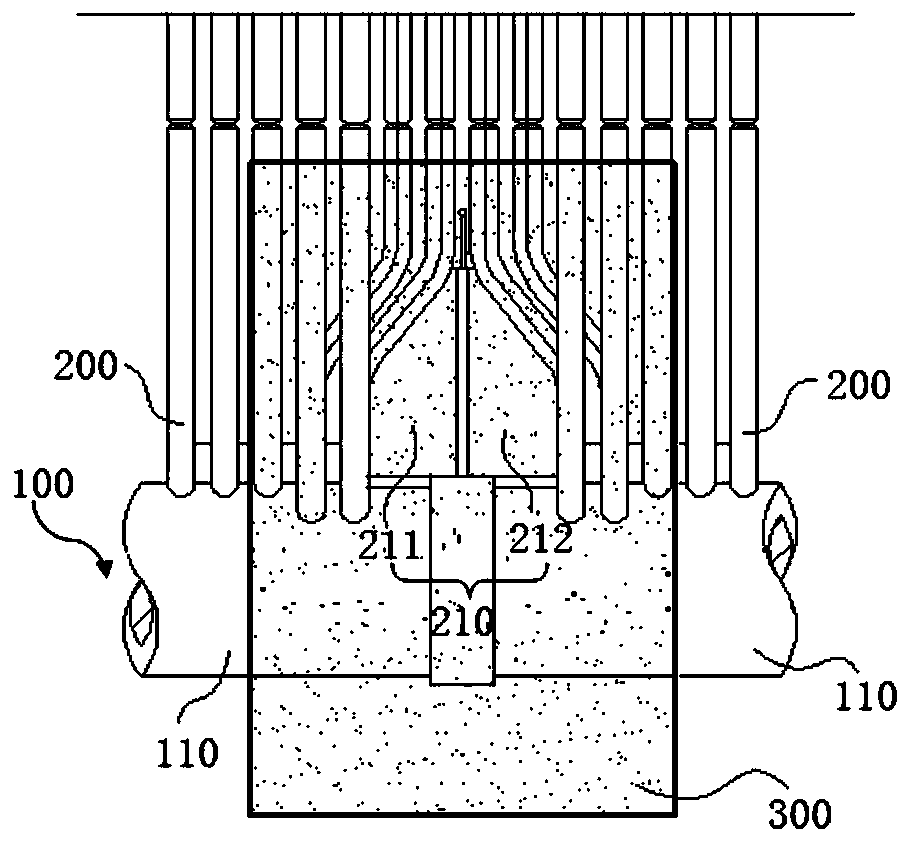

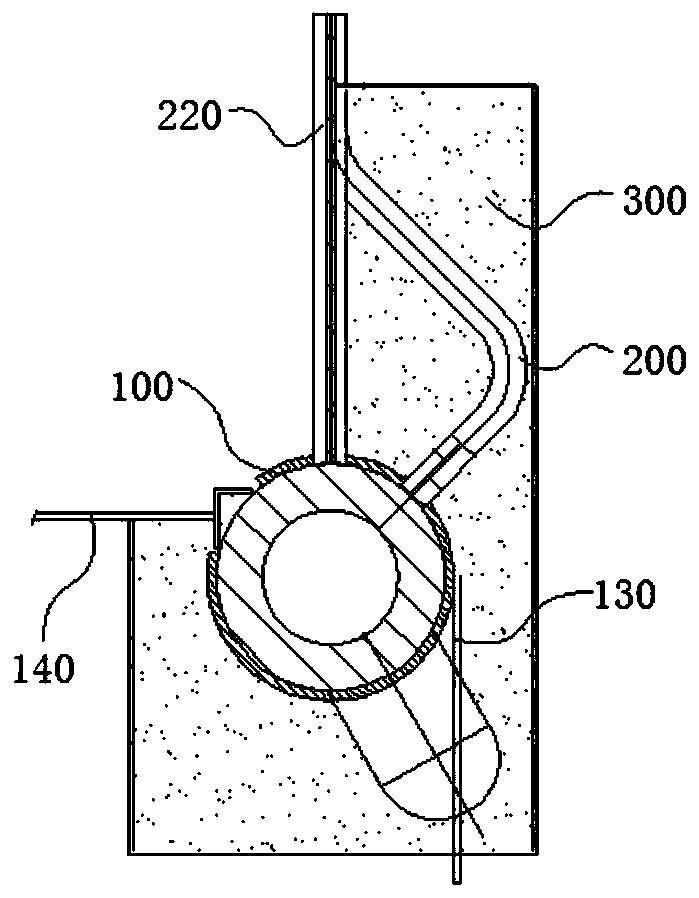

[0058] as combined Figure 1-Figure 9 , a boiler anti-expansion and cracking treatment method in this embodiment is mainly aimed at the method for technical improvement of boilers in the industry that are prone to expansion and cracks, and specifically includes a structural improvement method for the header 100 under the water wall, The structural improvement method of the front water wall at the ceiling floor, the structure improvement method of the ceiling outlet intermediate header 700, the structural improvement method of the connection between the middle partition wall and the side wall in the area of the side wall lower header 830, etc. At present, the water-cooled wall lower header 100 in the supercritical "W" flame boiler in the industry is composed of a plurality of water-cooled wall diversity boxes 110. The two water-cooled wall diversity boxes 110 are welded and fixed together, but due to the low strength of the welds at the joints, it is easy to cause unilateral ...

Embodiment 2

[0064] A kind of boiler anti-expansion pulling crack treatment method of this embodiment, its structure is basically the same as embodiment 1, further, as Figure 4-Figure 5 As shown, this embodiment also includes structural improvements to the front water-cooled wall at the ceiling and bottom plate, and the specific improvement method is as follows: Step B1: Weld the membrane between two adjacent membrane water-cooled wall tubes 500 located in the boiler ceiling and bottom plate area type sealing plate 520, and weld the pre-buried filling plate 510 at the height center position between two adjacent membrane type water-cooled wall tubes 500, wherein the membrane type sealing plate 520 and the pre-buried filling plate 510 are well-known boilers in the industry The conventional structural design in the area of the ceiling and floor will not be repeated here.

[0065] Step B2: Weld the flat steel 400 at the height center position outside the pre-embedded filling plate 510, the ...

Embodiment 3

[0068] A kind of boiler anti-expansion pulling crack treatment method of this embodiment, its structure is basically the same as embodiment 1, further, as Figure 6-Figure 8 As shown, this embodiment also includes structural improvements to the ceiling outlet intermediate header 700, wherein the ceiling outlet intermediate header 700 is composed of a plurality of intermediate diversity boxes, and a fixing device is used between two adjacent intermediate headers. Full welding The two intermediate headers are welded and fixed together in the form of welding, but due to the low strength of the welds at the joints, it is easy to cause unilateral weld de-soldering and other situations, and under the influence of thermal expansion, it is easy to damage the roof outlet intermediate header. The 700 is expanded and cracked, which affects the normal use of the ceiling outlet intermediate header 700. Therefore, for the structural improvement of the middle header 700 at the outlet of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com