Wiring area protection method in a touch screen manufacturing process

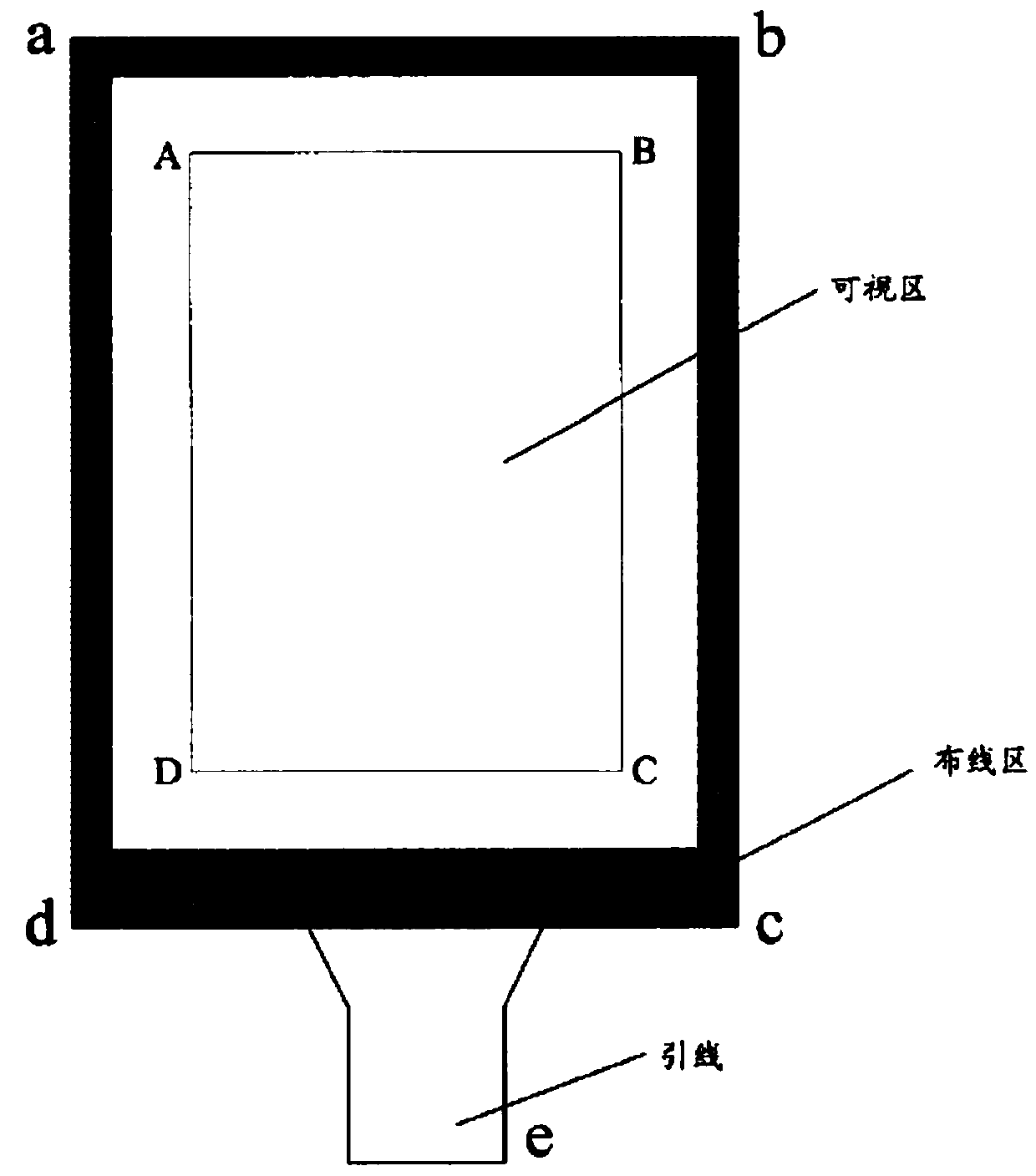

A production process and wiring area technology, applied in the field of wiring area protection, can solve problems such as disconnection, poor silk screen circuit, no wiring area protection, etc., to achieve the effects of improving production efficiency, saving production costs, and reducing defect rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

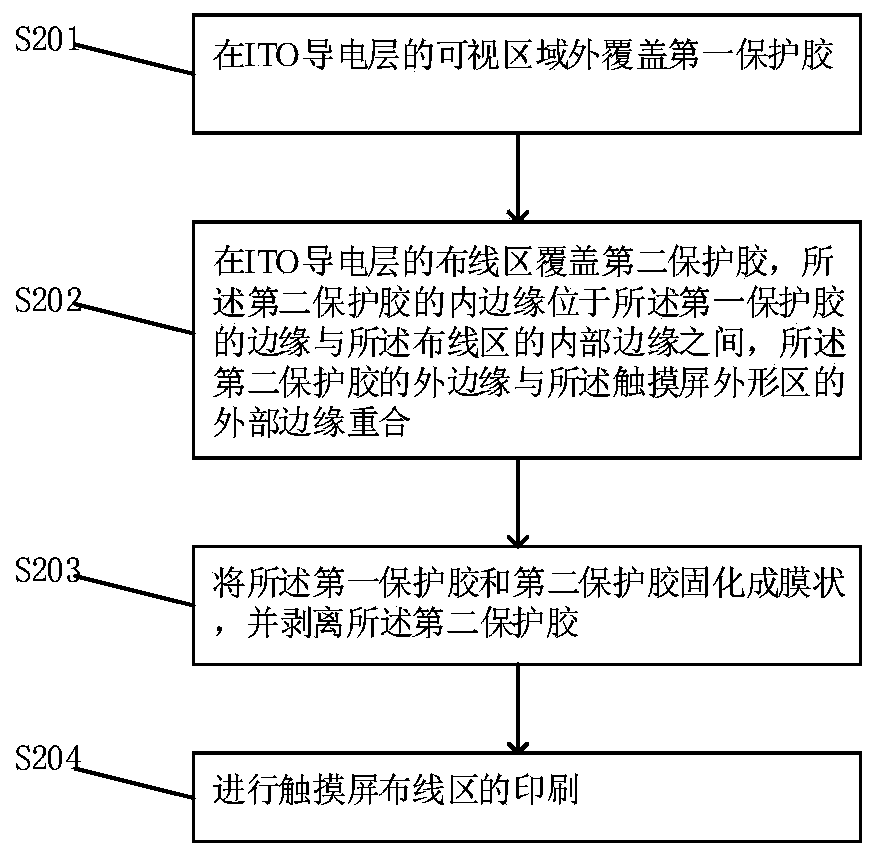

[0022] like figure 2 As described above, in an embodiment of the present invention, a method for protecting a wiring area in a touch screen manufacturing process, the method includes:

[0023] S201, covering the first protective glue outside the visible area of the ITO conductive layer;

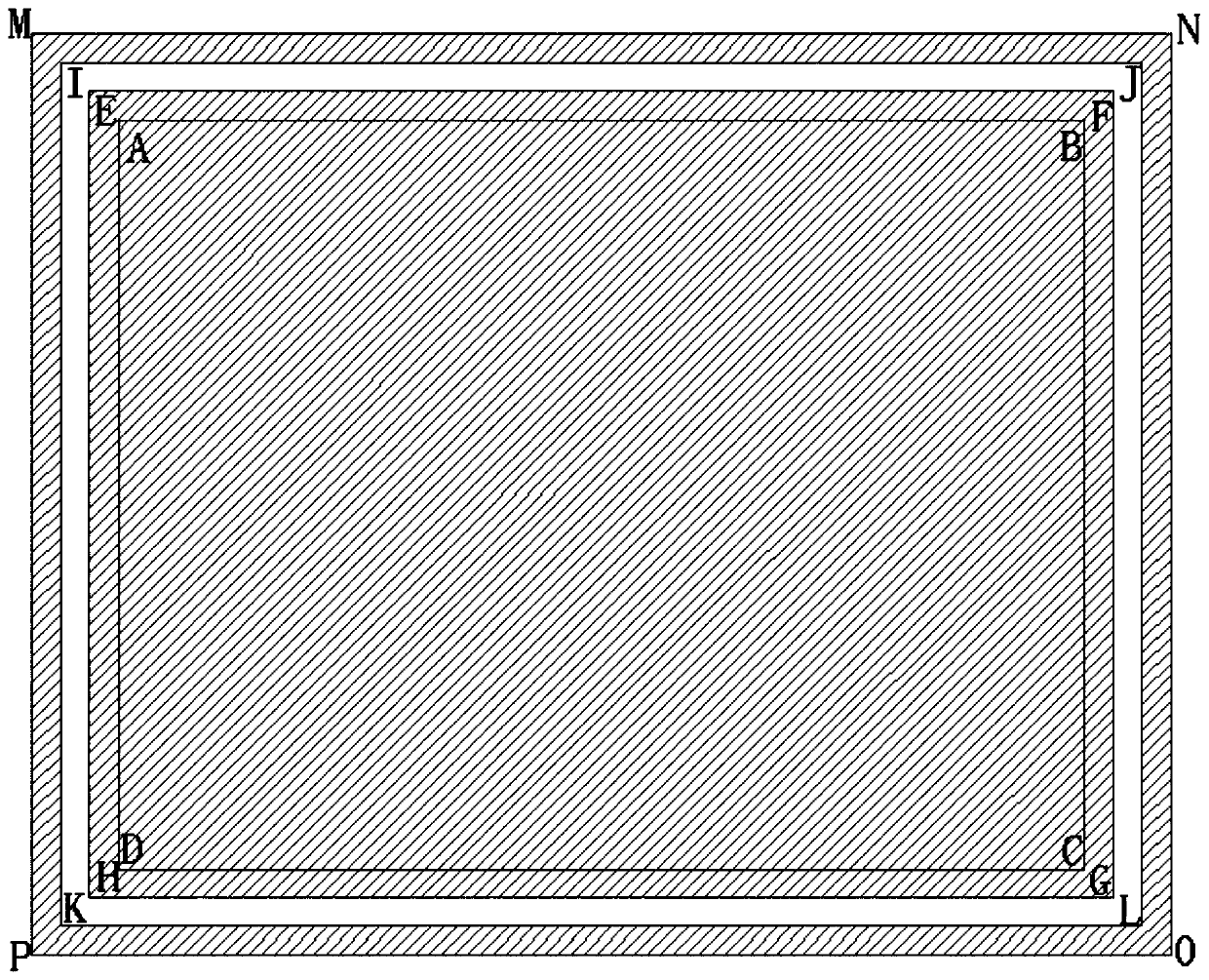

[0024] S202. Cover the wiring area of the ITO conductive layer with a second protective glue, the inner edge of the second protective glue is located between the edge of the first protective glue and the inner edge of the wiring area, and the second protective glue The outer edge of the outer edge coincides with the outer edge of the outline area of the touch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com