Design method of a volute

A design method, volute technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of deviation of calculation results from design intent, increase of flow loss, acceleration of volute gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Embodiment: the specific process of the volute design of a certain industrial subsonic centrifugal compressor is as follows:

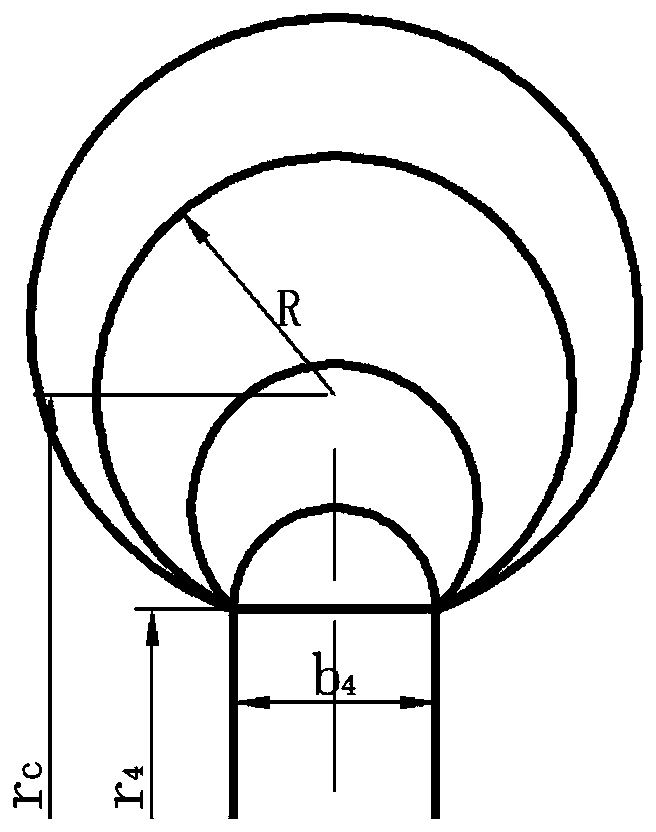

[0089] 1) The flow parameters at the inlet section of the volute are given, including: volumetric flow q at the inlet of the volute v4 =2.5177m 3 / s, the tangential component of the absolute velocity at the inlet of the volute c u4 =109.45m / s; Given the design geometric parameters of the volute, including: the radius r of the volute inlet 4 =0.32m, volute inlet width b 4 = 0.024m.

[0090] 2) Use formula (1) to calculate the initial section azimuth of the volute

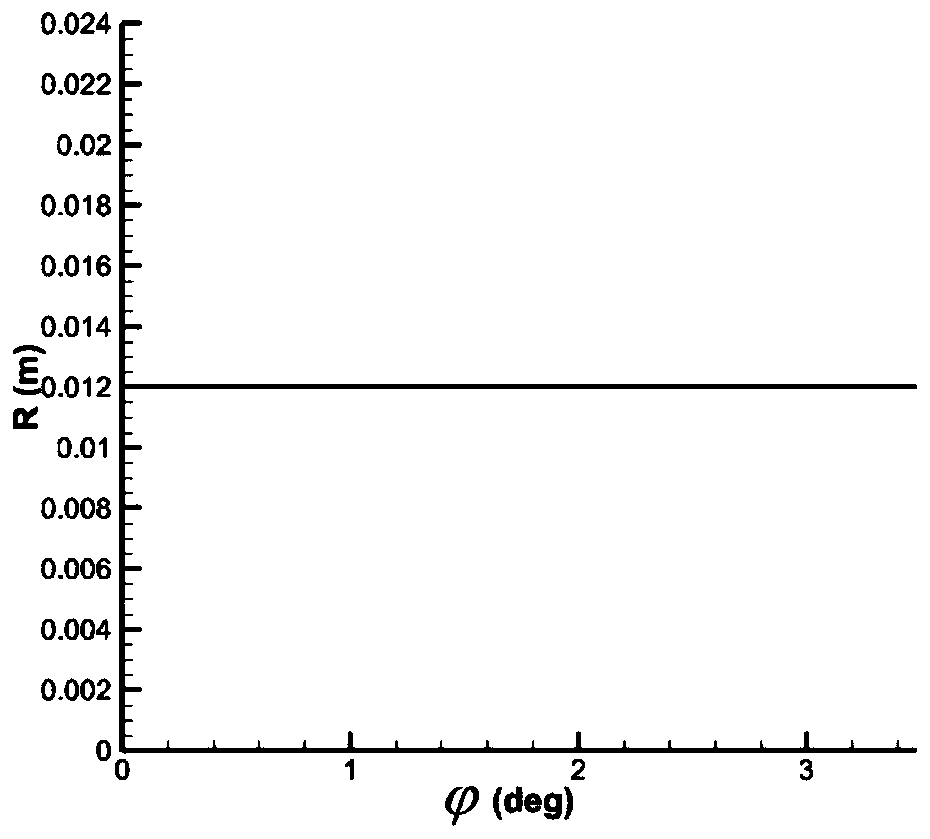

[0091] 3) The azimuth angle of the volute section in the range of Corresponding volute section circle radius R 1 are given as R 1 =0.012m, azimuth angle of volute section and volute section circle radius R1 exist The functional relationship in the range is as image 3 shown.

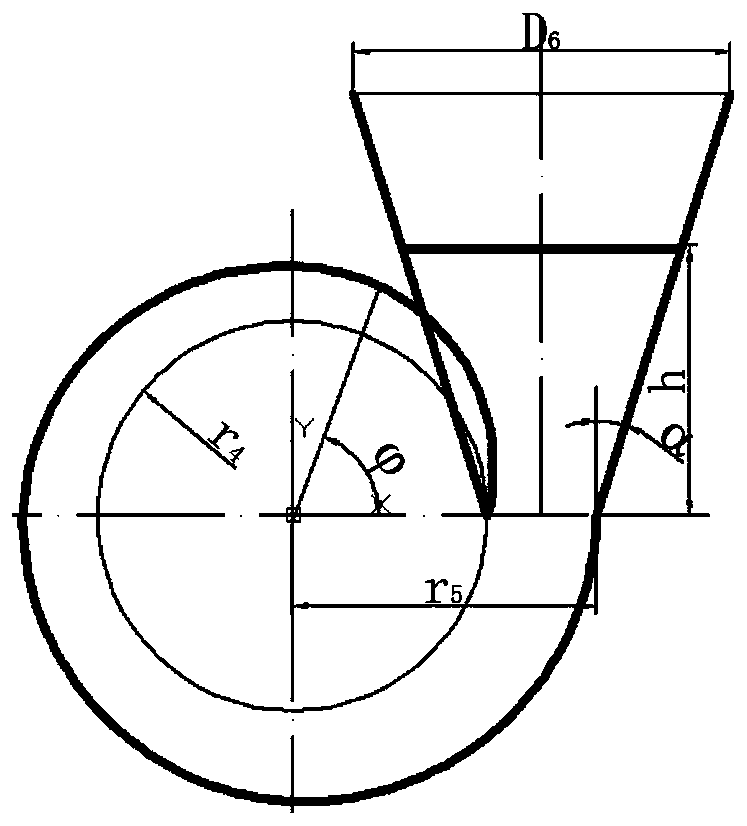

[0092] 4) Set the azimuth angle of the volute section in the range of In this range,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com