Motor mechanical parameter identification method and system based on high-order sliding-mode observer

A high-order sliding mode, sliding film observer technology, applied in control systems, control generators, vector control systems, etc., can solve the problems of reducing the accuracy of identification results, attenuation, and delay amplitude of identification results, and achieve the realization of The effect of mechanical parameter identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with examples.

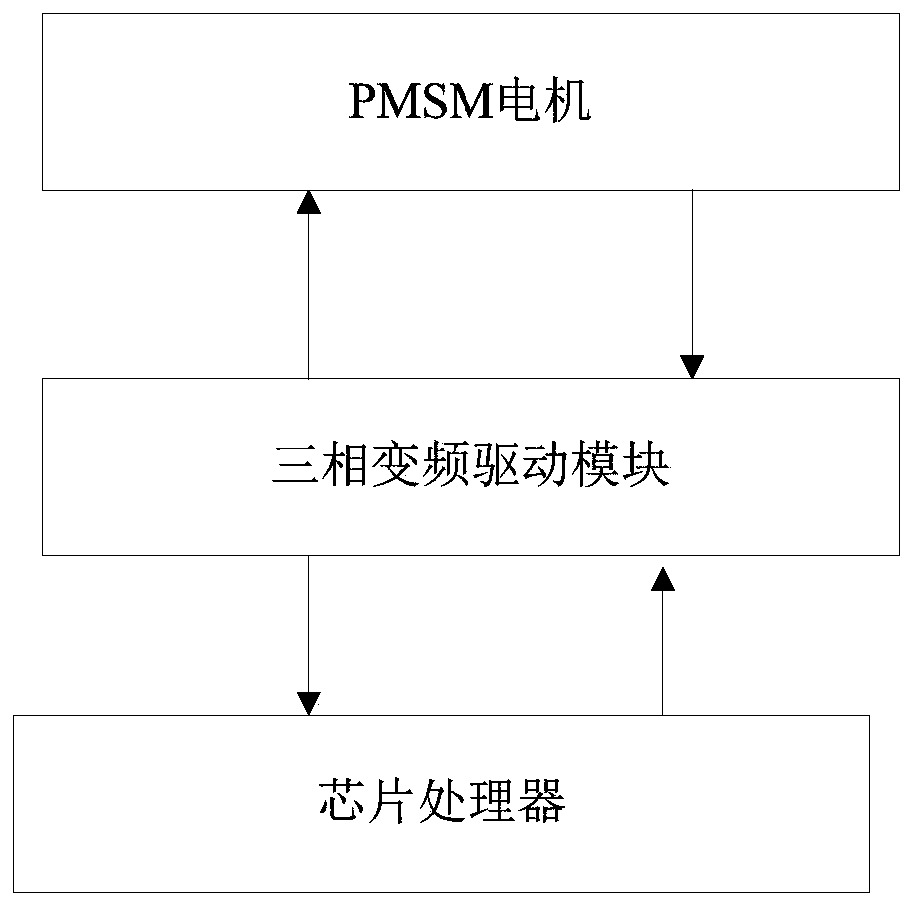

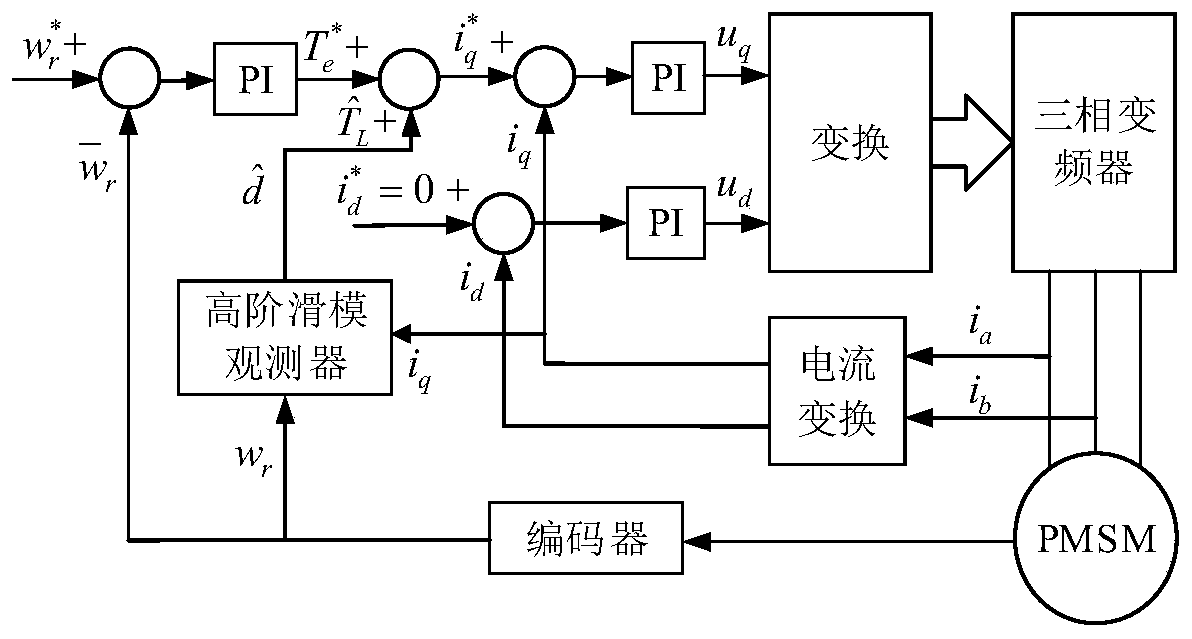

[0069] figure 1 and figure 2 They are respectively a structural module diagram and a structural block diagram of a motor mechanical parameter identification system based on a high-order sliding mode observer in the present invention. Such as figure 1 and figure 2 As shown, the system includes a sequentially connected PMSM motor, a three-phase variable frequency drive module, and a chip processor. In this embodiment, a permanent magnet synchronous motor is taken as an example for illustration.

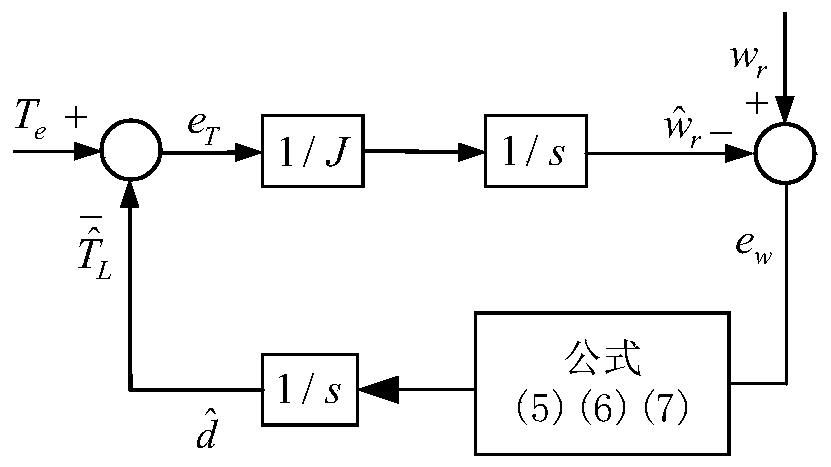

[0070] Among them, the three-phase frequency drive module collects the current signal of the motor and the speed signal w r , and sent to the chip processor, the current signal includes the actual value of the motor q-axis current i q and d-axis current actual value i d . Among them, the information collection can be realized by using the existing current sampling module and the photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com