No-tillage anti-blocking ditcher

A trench opener and anti-blocking technology, applied in the direction of excavation/covering of trenches, planting methods, shovels, etc., can solve the problems of affecting the forward resistance, large traction, etc., to prevent blockage, good ability to enter the soil, and flexible trenching effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

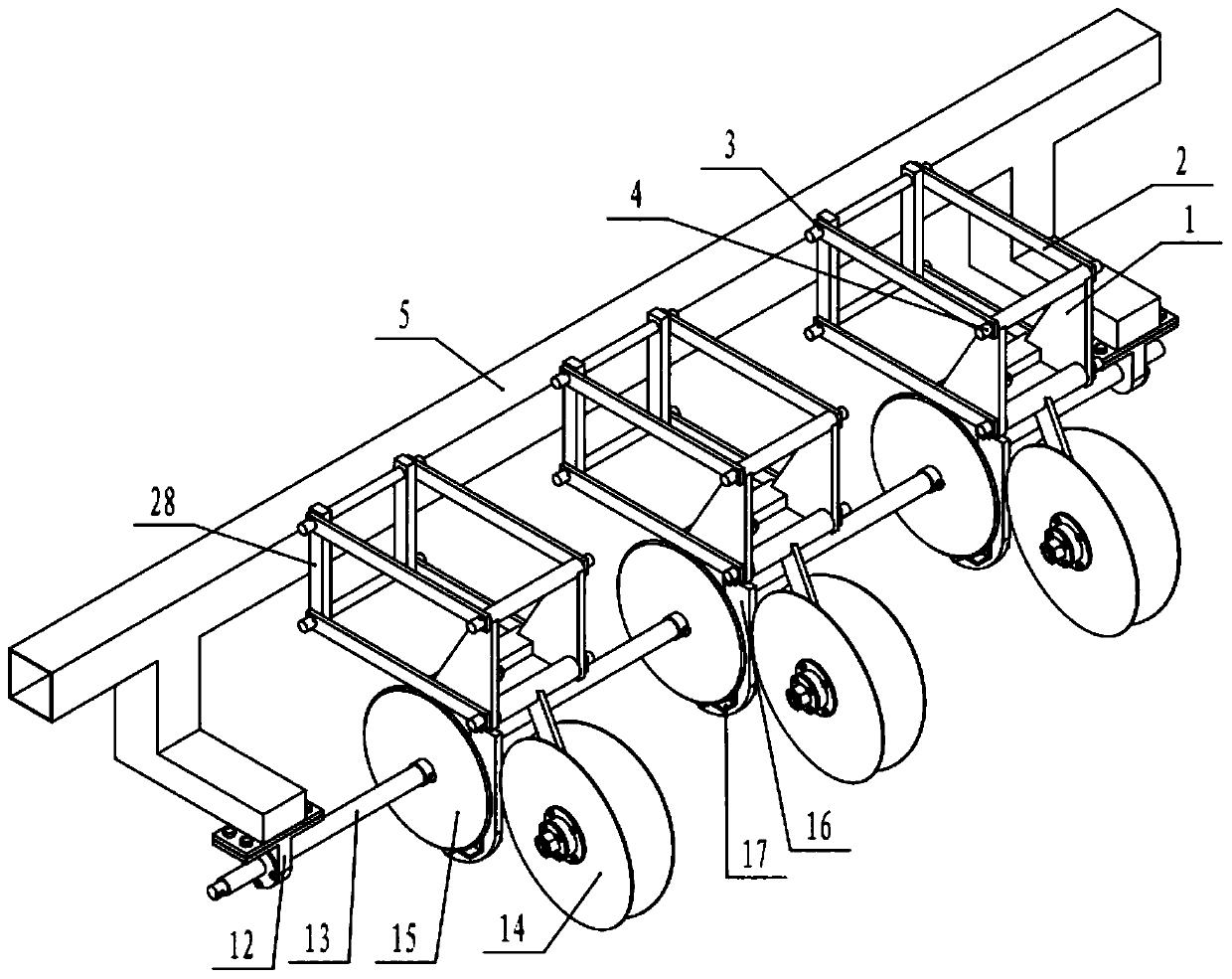

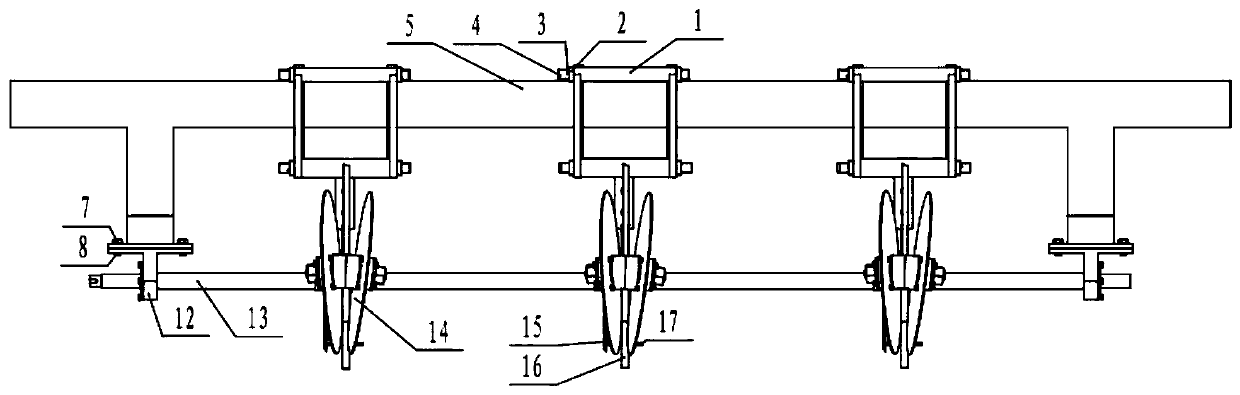

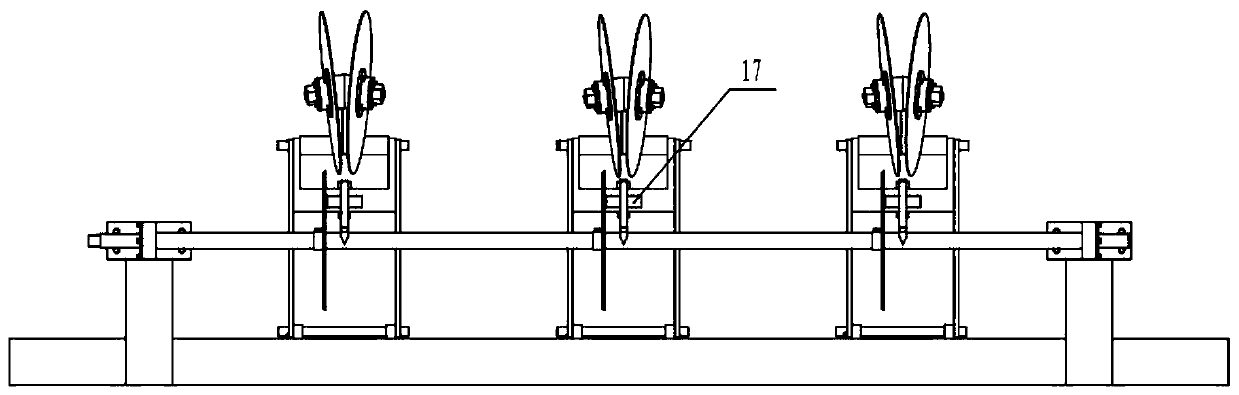

[0032] Embodiment 1: as Figure 1-Figure 9 As shown, a no-tillage anti-blocking ditch opener includes a stubble breaking mechanism, an anti-blocking device and a ditching device. The profiling mechanism is connected on the frame 5 and the stubble breaking mechanism is positioned at the ditching device and is positioned at the stubble breaking mechanism rear side, and the anti-blocking device is installed beside the stubble breaking mechanism.

[0033] Preferably, the above-mentioned stubble breaking mechanism includes a main cutter body 16, and the main cutter body 16 includes a straight line section of an integral structure and an arc section with a blade bent forward, and the two sides of the arc section are symmetrically fixed and connected to the knife wings 17 by countersunk rivets. The main purpose of the blade is to slide and cut stubble and weeds and divert them to both sides, so as not to accumulate and block. The shape of the blade is an isosceles right triangle, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com