Self-walking polishing equipment

A self-propelled and equipment technology, applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve problems such as difficult to achieve polishing effect and efficiency, unable to automatically control polishing quality, and increase energy consumption. Achieve the effects of saving walking energy, controllable polishing quality, and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The present invention refers to the moving direction of the wallboard production line, defines the direction consistent with the moving direction as the longitudinal direction, and accordingly defines the direction perpendicular to the moving direction in the moving plane as the horizontal direction; and defines the direction perpendicular to the moving plane Defined as height direction.

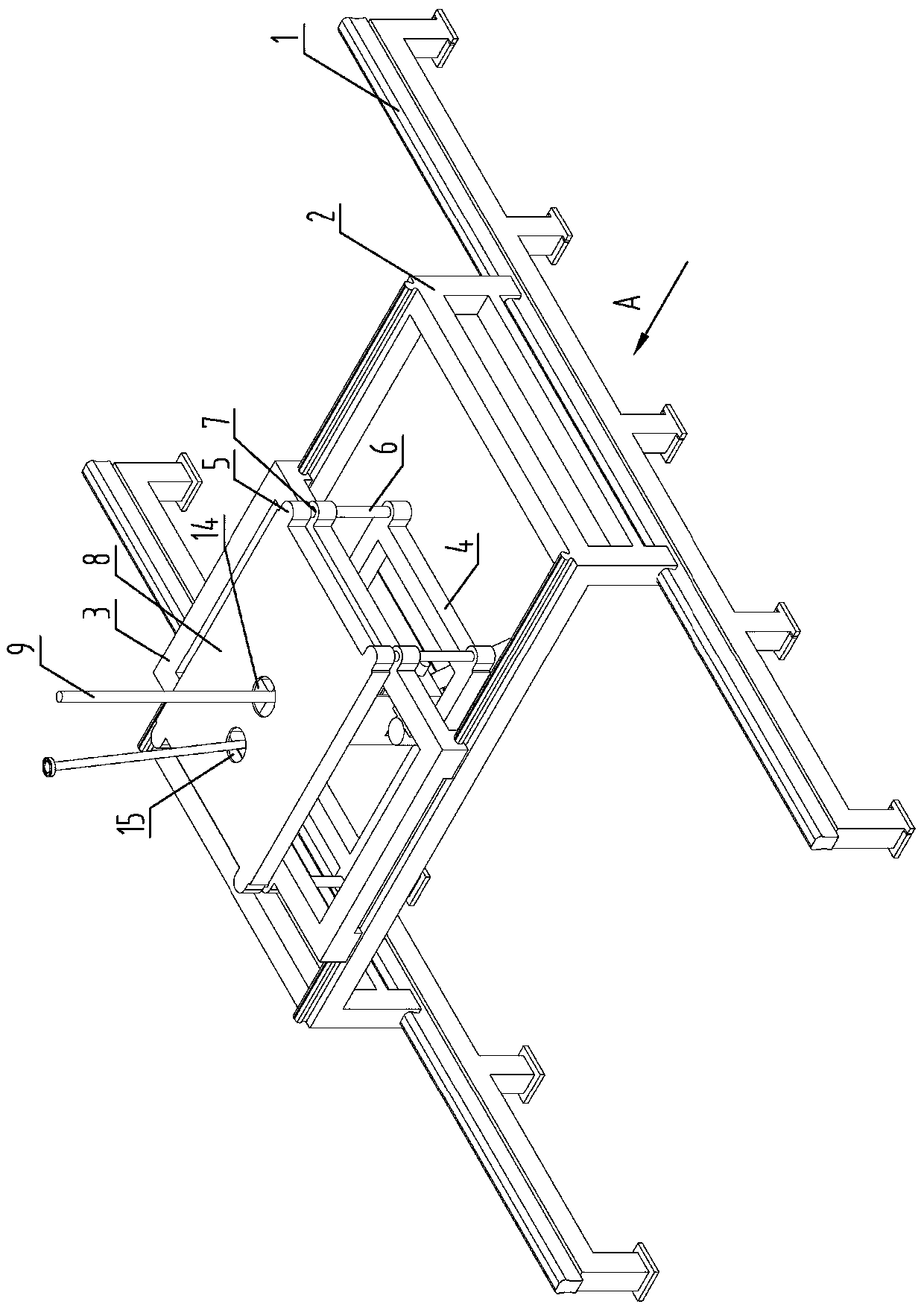

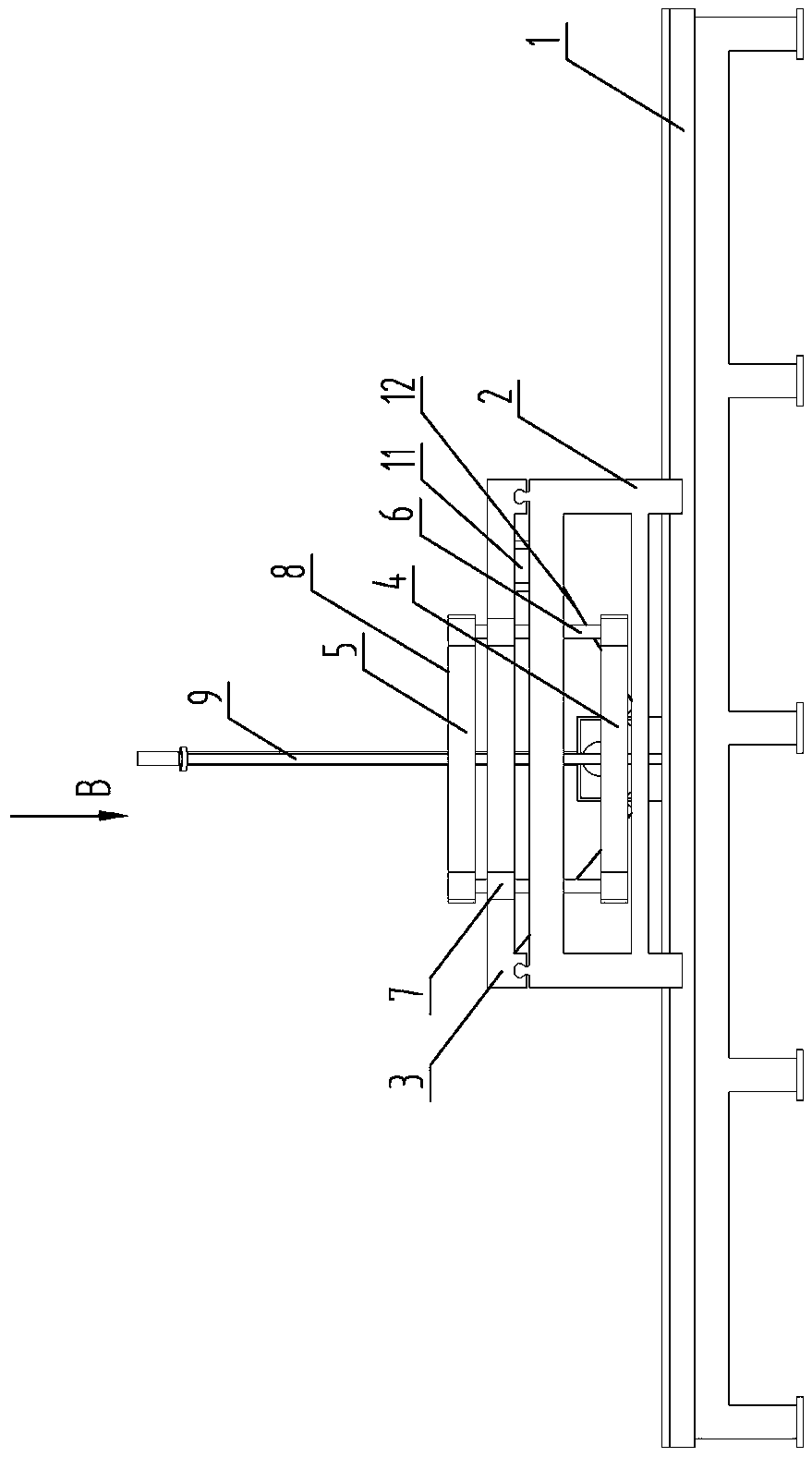

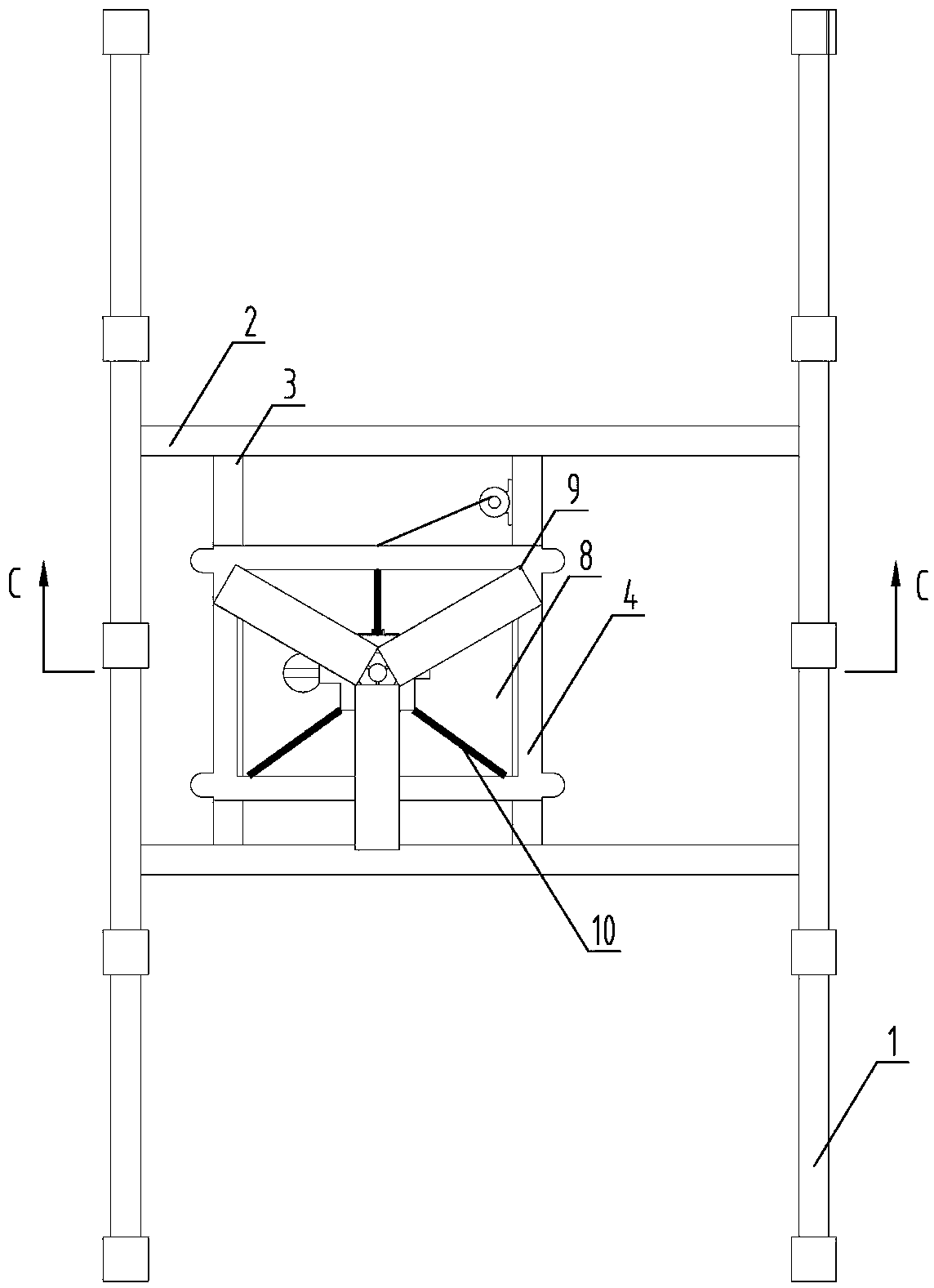

[0041] Such as figure 1 and figure 2 As shown, the present invention equips the first carriage 2 in the base 1, and the first carriage 2 can move longitudinally, and the second carriage 3 is equipped on the first carriage 2, and the second carriage 3 can move laterally, and the second carriage 3 can move laterally. Offer guide hole 7 on the two carriages 3, guide rail 6 is equipped in the guide hole 7, the upper end of guide rail 6 fixes u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com