Six-arm polyethylene glycol amino hydrogel, its preparation method and application

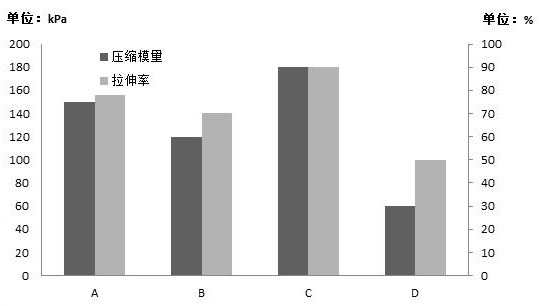

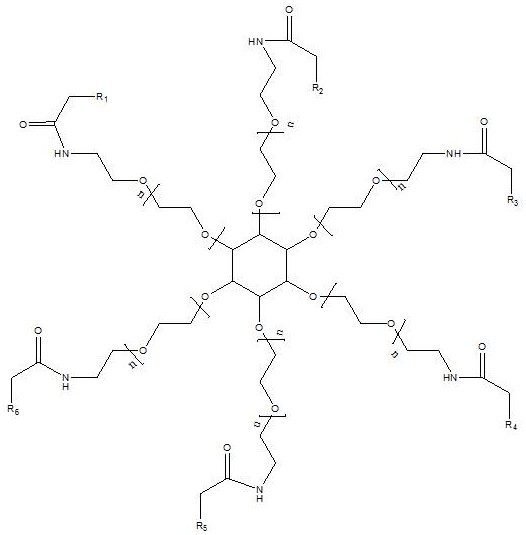

A technology of polyethylene glycol amino and polyethylene glycol, which is applied in the field of preparation of new six-arm polyethylene glycol hydrogel, can solve the problems of slow response rate of hydrogel and limitation of hydrogel, and achieve external response Fast, low cost, strong in vitro mechanical properties and excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

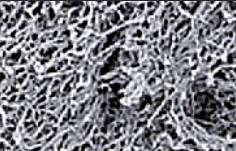

[0054] Preparation of six-arm polyethylene glycol hydrogel

[0055] Using six-arm polyethylene glycol amino (n=30) as the raw material of six-arm polyethylene glycol and diethylenetriaminepentaacetic acid as the raw material of polycarboxy compounds, prepare six-arm polyethylene glycol amino hydrogel: weigh diethylene Triaminepentaacetic acid (3mmol), acetic anhydride (2mmol), uniformly mixed and stirred for 12 hours, added 8g six-arm polyethylene glycol amino (1mmol) to the mixture, and added N-methylmorpholine (0.4mmol) simultaneously and mixed Evenly, after stirring for 2 hours, let it stand at room temperature for 12 hours at 35°C. The obtained gel was soaked in ethanol for 1 hour, then the ethanol was filtered off with suction, and the ethanol was filtered off three times. After soaking in water for 1 hour, the suction filtration was repeated three times, and a colorless transparent hydrogel material was obtained.

Embodiment 2

[0057] Preparation of six-arm polyethylene glycol hydrogel

[0058] Using six-arm polyethylene glycol amino (n=10) as the raw material of six-arm polyethylene glycol and diethylenetriaminepentaacetic acid as the raw material of polycarboxy compound, prepare six-arm polyethylene glycol amino hydrogel: weigh diethylene Triaminepentaacetic acid (3mmol), acetic anhydride (3mmol), uniformly mixed and stirred for 12 hours, added 8g six-arm polyethylene glycol amino (1mmol) to the mixture, and simultaneously added pyridine (0.5mmol) and mixed uniformly, stirred for 2 hours Then stand at 45°C for 12h. The obtained gel was soaked in ethanol for 1 hour, then the ethanol was filtered off with suction, and the ethanol was filtered off three times. After soaking in water for 1 hour, the suction filtration was repeated three times, and a colorless transparent hydrogel material was obtained.

Embodiment 3

[0060] Preparation of six-arm polyethylene glycol hydrogel

[0061] Using six-arm polyethylene glycol amino (n=20) as the raw material of new six-arm polyethylene glycol and diethylenetriaminepentaacetic acid as the raw material of polycarboxy compound, prepare six-arm polyethylene glycol amino hydrogel: weigh two Ethylenetriaminepentaacetic acid (3mmol), acetic anhydride (2mmol), uniformly mixed and stirred for 12 hours, added 8g six-arm polyethylene glycol amino (1mmol) to the mixture, and simultaneously added triethylamine (0.1mmol) and mixed uniformly, After stirring for 2 hours, stand at 50°C for 12h. The obtained gel was soaked in ethanol for 1 hour, then the ethanol was filtered off with suction, and the ethanol was filtered off three times. After soaking in water for 1 hour, the suction filtration was repeated three times, and a colorless transparent hydrogel material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com