Cutting insert

A cutting tool and cutting edge technology, applied to cutting blades, tools for lathes, milling cutters, etc., can solve the problems of reduced service life of the cutting tool 20, reduced cutting quality, and easy damage of the cutting tool 20, and achieve smooth cutting Process, the effect of effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

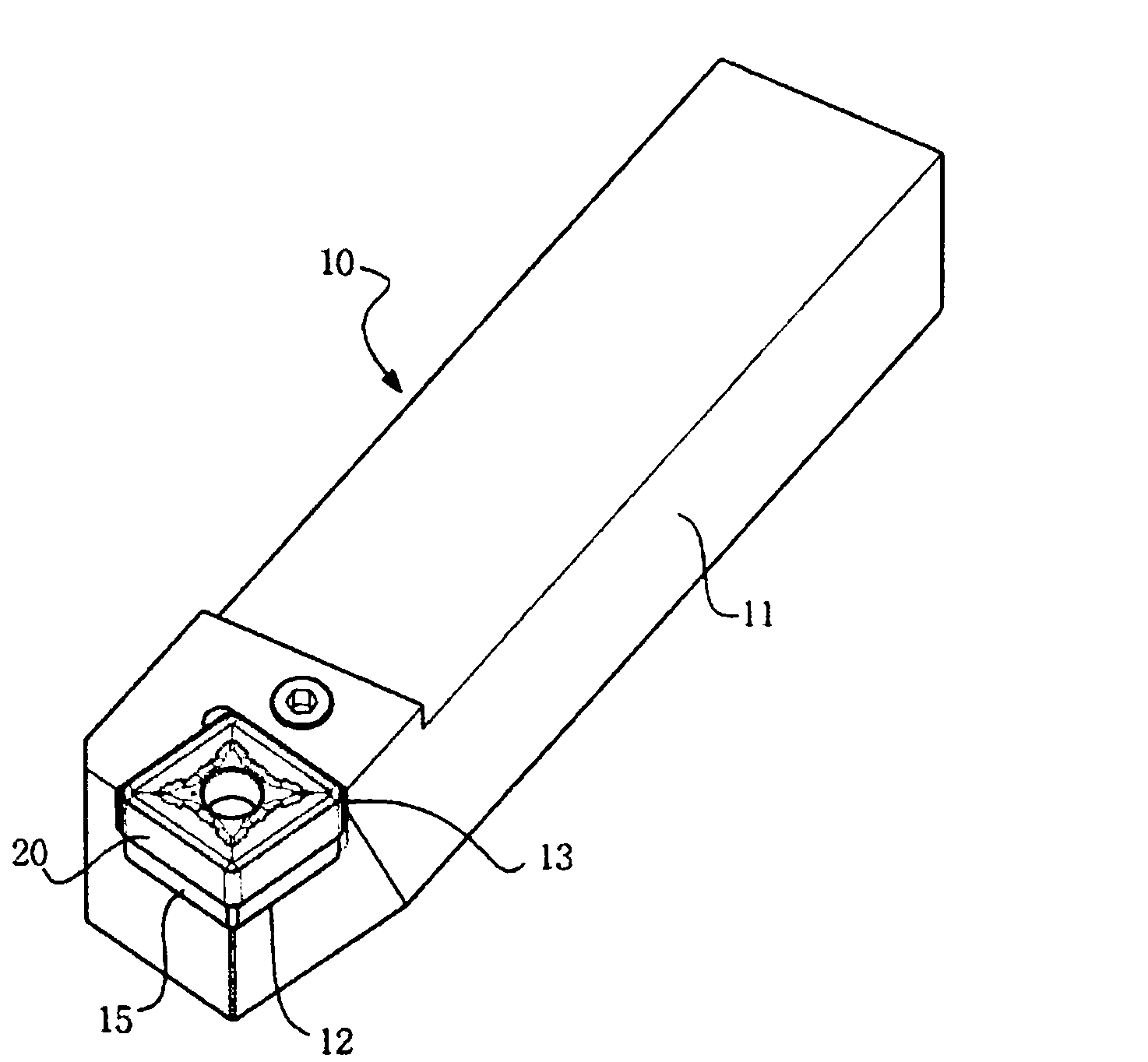

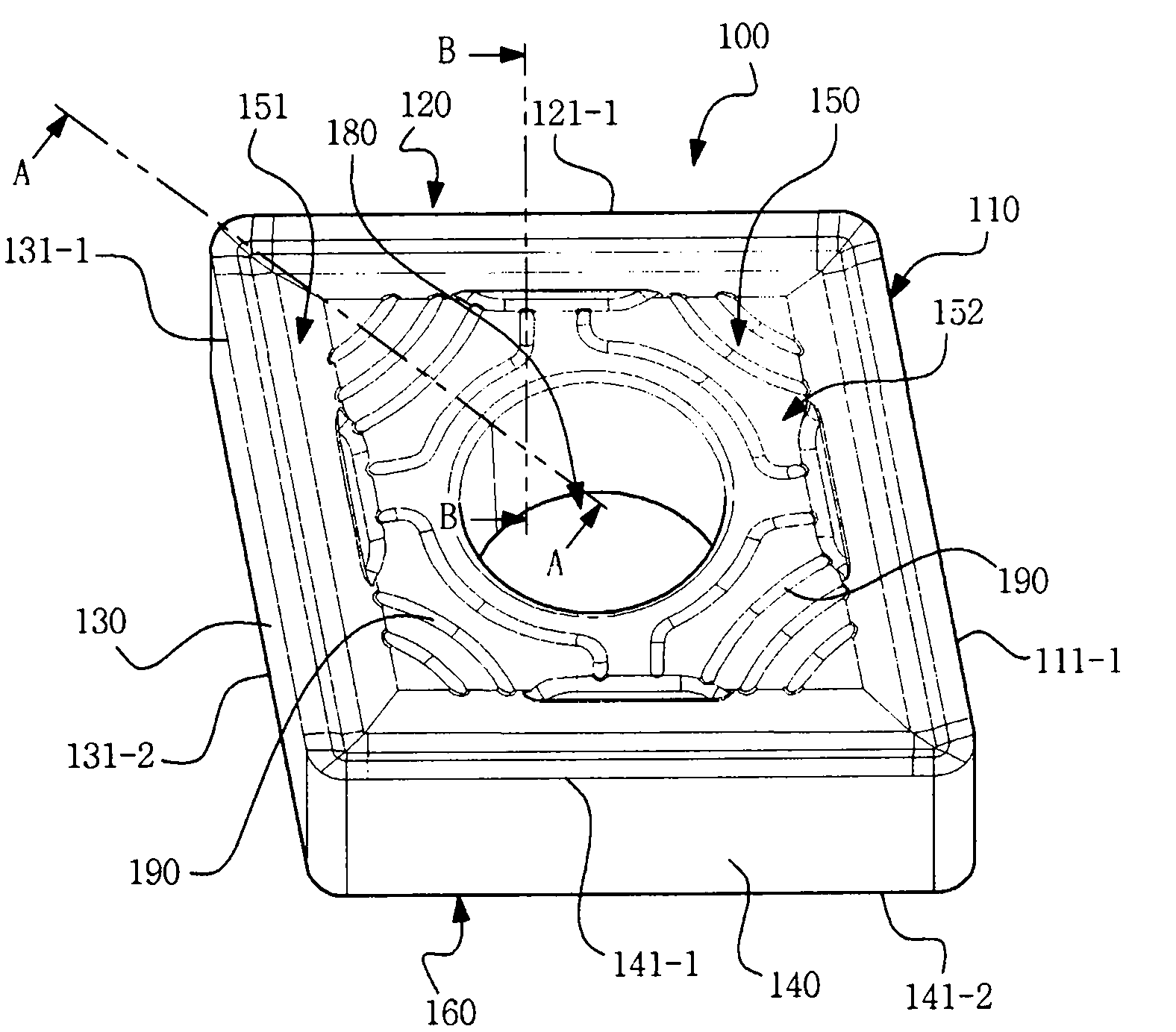

[0027] Hereinafter, a cutting tool according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

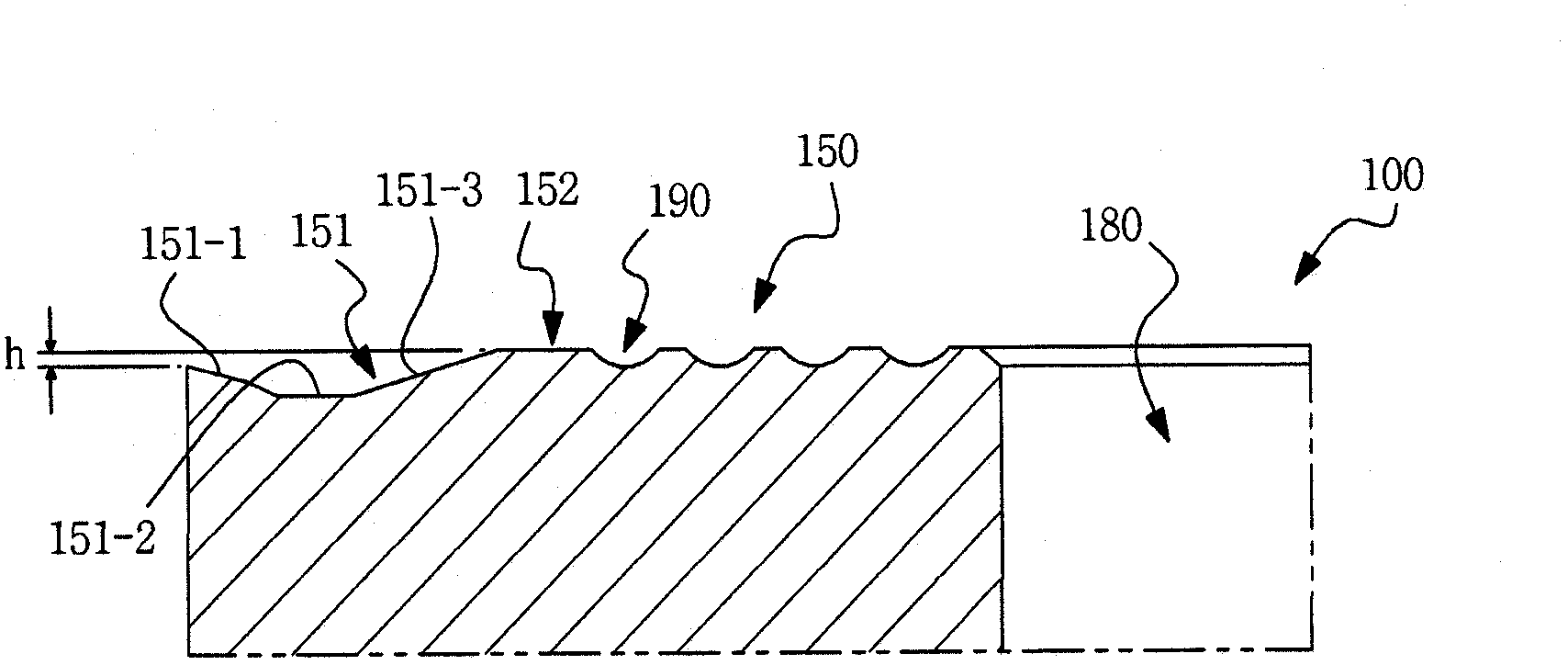

[0028] figure 2 is a perspective view of a cutting tool according to a first embodiment of the present invention, image 3 is along figure 2 The cross-section drawn by the line A-A and Figure 4 is along figure 2 Sectional drawing made by line B-B. To simplify the drawings, in image 3 and Figure 4 Only the top surface of the tool is shown in .

[0029] The cutting tool 100 according to the first embodiment of the present invention has a top surface 150 and a bottom surface 160 facing each other, four (4) side surfaces 110 , 120 , 130 and 140 connecting the top surface 150 and the bottom surface 160 . Here, the through hole 180 passes through the central portion of each of the top surface 150 and the bottom surface 160 and serves as a clamping hole when the cutting tool 100 is mounted to the tool h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com