Device and method for oxidizing organic substances in wastewater through ultraviolet catalysis of ozone

A technology of ozone oxidation and ultraviolet light, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problem that the uniform irradiation of ultraviolet light is not well considered, and the wavelength of ultraviolet light is not considered more. The effect is not obvious, etc., to achieve the effect of increasing the contact ratio, improving the utilization rate, and lowering the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

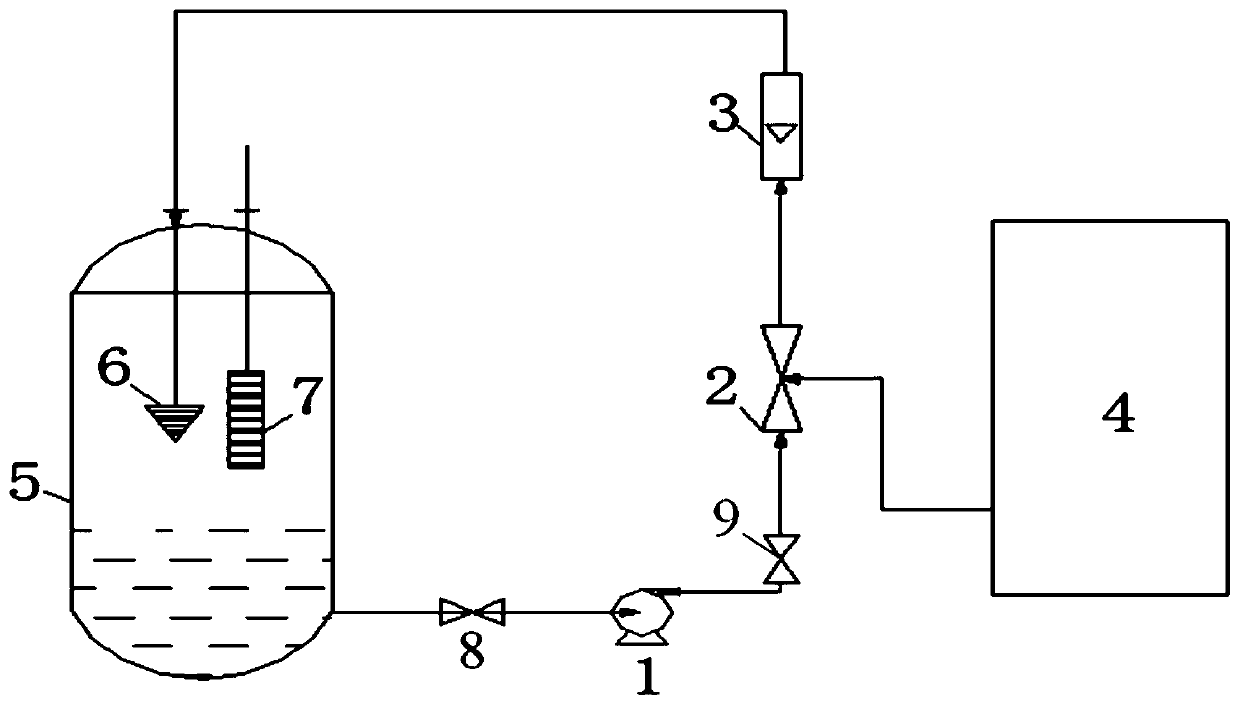

[0034] like figure 1 As shown, a device for ultraviolet photocatalytic ozonation of organic matter in wastewater, including a liquid inlet pump 1, a Venturi jet 2, a rotameter 3, an ozone machine 4, a reaction tank 5, an atomizing nozzle 6 and an ultraviolet lamp assembly 7 . The inlet of the liquid inlet pump 1 is connected with the outlet of the reaction tank 5, the outlet of the liquid inlet pump 1 is connected with the first inlet of the Venturi ejector 2, and the second inlet of the Venturi ejector 2 is connected with the outlet of the ozone machine 4 The outlet of the Venturi jet 2 is connected with the rotameter 3 , the rotameter 3 is connected with the atomizing nozzle 6 , and the atomizing nozzle 6 and the ultraviolet lamp assembly 7 are both arranged in the reaction tank 5 .

[0035] The inlet pump 1 includes an inlet valve 8 and an outlet valve 9 , the inlet valve 8 is arranged between the inlet pump 1 and the reaction tank 5 , and the outlet valve 9 is arranged be...

Embodiment 2

[0043] A comparative experiment with or without a UV reflector in the UV catalytic reaction area:

[0044] Place an ultraviolet lamp tube with a diameter of 3 cm and a length of 20 cm in the center of an ultraviolet catalytic reaction cylinder with a diameter of 20 cm and a length of 50 cm, and set the ultraviolet wavelength of the ultraviolet lamp between 100 and 200 nm; The instrument is placed in the middle of the ultraviolet lamp tube and the reaction cylinder, and the distribution of the ultraviolet intensity under the UV reflector and without the reflector is compared (0 degrees means that the intensity meter of the ultraviolet 254nm wavelength is facing the ultraviolet lamp, and it is done every 90 degrees. Measurement, when 180 degrees, the ultraviolet light intensity meter is facing away from the lamp tube), and its data are shown in Table 1:

[0045] Table 1 UV intensity with and without UV reflector

[0046] UV intensity (uW / cm 2 )

[0047] It can be se...

Embodiment 3

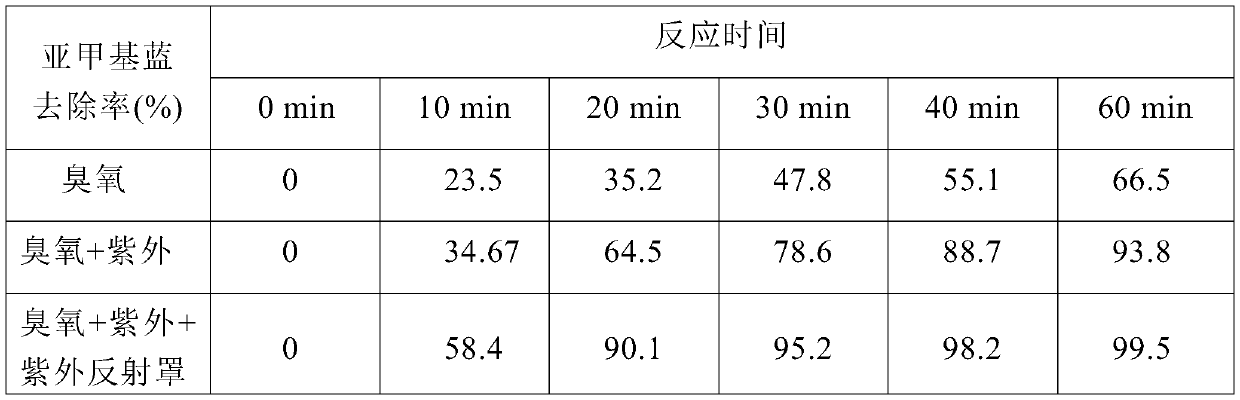

[0049] Test the 0.015% methylene blue solution by using the ozone oxidation device in Example 1, compare ozone under the same conditions, ozone+ultraviolet, ozone+ultraviolet+the removal rate of organic matter under the ultraviolet reflector, its data are shown in Table 2 :

[0050] Table 2: Removal rates of methylene blue under the conditions of ozone, ozone+UV, ozone+UV+UV reflector in different reaction times

[0051]

[0052] As can be seen from Table 2, under the situation of ozone+ultraviolet lamp+ultraviolet reflector, the removal rate of methylene blue is the highest. It can be seen that the present invention can effectively improve the efficiency of ultraviolet photocatalytic ozonation, greatly reduce the reaction time, improve the efficiency, and reduce the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com