Sterilization device and method for microbe fermentation water

A technology of microbial fermentation, disinfection and sterilization, applied in the field of microbial fermentation, can solve the problems of incomplete sterilization microbial fermentation production, high energy consumption, high sterilization time, low energy consumption, etc., so as to overcome incomplete sterilization and sterilization effect. Good and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

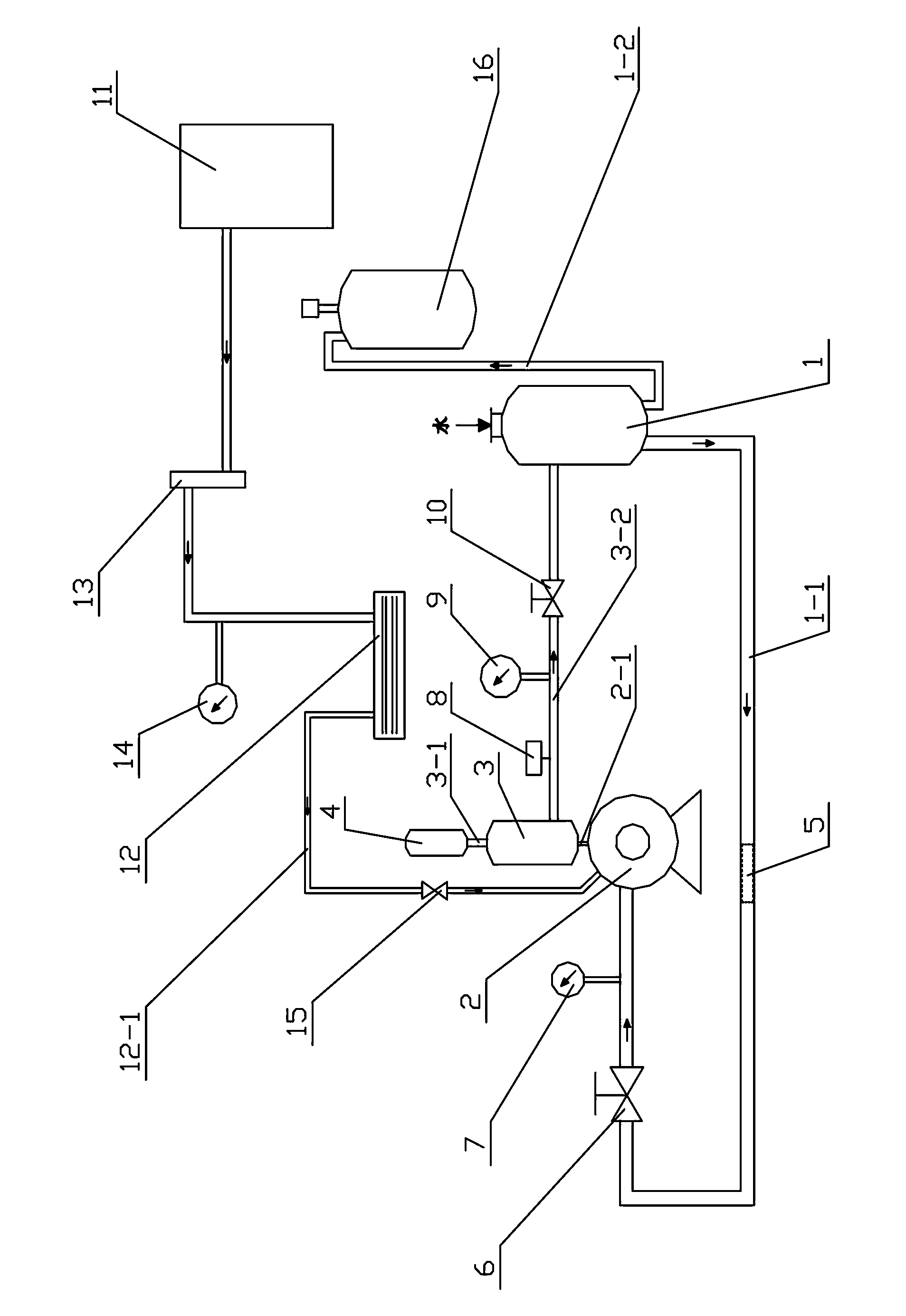

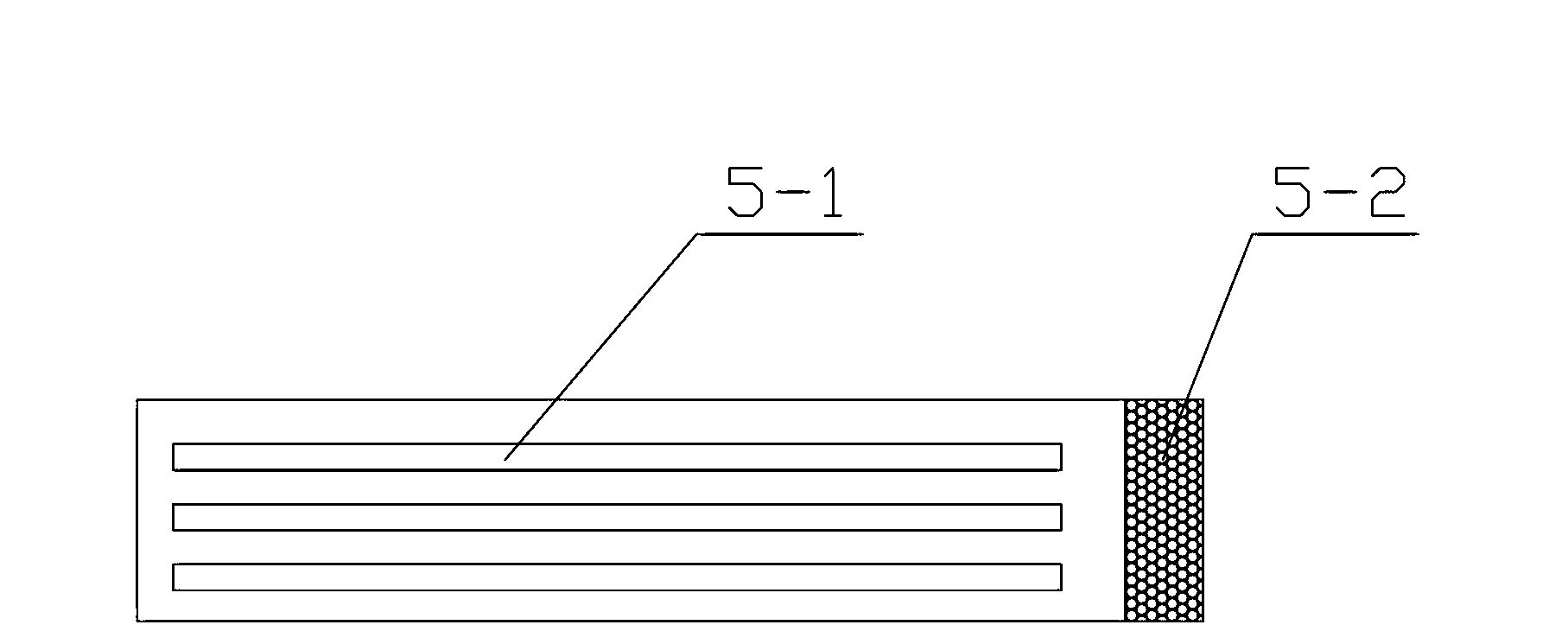

[0038] Such as figure 1 and figure 2 Shown is a kind of equipment that applies ozone disinfection water to microbial fermentation, the equipment includes a water treatment system and an ozone unit; the water treatment system includes a water storage tank 1, and the bottom of the water storage tank 1 is provided with a The mixing pump 2 is connected and is used to send the water in the water storage tank 1 into the first liquid outlet pipe 1-1 in the gas-liquid mixing pump 2, and the sterile pipeline 1-2 communicating with the fermenter 16; The liquid outlet of the gas-liquid mixing pump 2 is provided with a second liquid outlet pipe 2-1 communicated with the gas-liquid separation tank 3, and the top of the gas-liquid separation tank 3 is provided with an It is used to send the gas separated in the gas-liquid separation tank 3 into the first gas outlet pipe 3-1 in the tail gas processor 4. One side of the gas-liquid separation tank 3 is provided with a water storage tank 1 fo...

Embodiment 2

[0047] Adopt the equipment of embodiment 1 to carry out disinfection and sterilization to microbial fermentation water:

[0048] Step 1. Close the sterile pipeline 1-2 of the water storage tank 1, close the ozone eliminator 5, inject 900L of water into the water storage tank 1, turn on the gas-liquid mixing pump 2, and the water passes through the first liquid outlet pipe 1-1 Flow into the gas-liquid mixing pump 2 from the water storage tank 1, and control the opening degree of the first valve 6 so as to adjust the flow rate of water in the first liquid outlet pipe 1-1 so that the vacuum degree of the vacuum gauge 7 is 0.005MPa, which means The measured volume flow rate of water is 30L / min;

[0049] Step 2: Start the oxygen generator 11 to produce oxygen, adjust the oxygen flow rate, wait for the pressure of the second pressure gauge 14 to reach 0.015MPa, keep it for 3 minutes, start the ozone generator 12 to prepare ozone, and open the stop valve 15 at the same time to make t...

Embodiment 3

[0054] Adopt the equipment of embodiment 1 to carry out disinfection and sterilization to microbial fermentation water:

[0055] Step 1. Close the sterile pipeline 1-2 of the water storage tank 1, close the ozone eliminator 5, inject 1000L of water into the water storage tank 1, turn on the gas-liquid mixing pump 2, and the water passes through the first liquid outlet pipe 1-1 Flow into the gas-liquid mixing pump 2 from the water storage tank 1, and control the opening degree of the first valve 6 so as to adjust the flow rate of water in the first liquid outlet pipe 1-1 so that the vacuum degree of the vacuum gauge 7 is 0.015MPa. The volume flow rate of water measured at the time is 20L / min;

[0056] Step 2: Start the oxygen generator 11 to produce oxygen, adjust the oxygen flow rate, wait for the pressure of the second pressure gauge 14 to reach 0.030MPa, keep it for 5 minutes, start the ozone generator 12 to prepare ozone, and open the stop valve 15 at the same time to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com