Preparation method of continuous aroma enhancement type solid aromatic bead for cigarette

A tobacco flavoring and solid state technology is applied in the field of preparation of continuous aromatizing solid incense beads for cigarettes, which can solve the problems that the incense beads cannot provide users with a uniform and stable aromatizing experience, residues, and poor aromatizing effects, and achieves continuous and stable aromatization. The effect of incense experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Add 10g of soybean lecithin to 20 times the weight of absolute ethanol, stir at 45°C, and the stirring speed is 1000r / min. After the dissolution is complete, slowly add 100g of peppermint oil and 150g of 20% Tween 80 solution, and continue stirring 45min, obtain emulsion;

[0040] (2) Add 200g of ethyl cellulose (90mPa·s) to the emulsion, keep stirring at 45°C for 30min at a stirring speed of 800r / min, let cool and add 80g of hydroxypropylmethylcellulose (3000mPa·s ), continue to stir for 1h, then concentrate the solution in vacuum to one-third of the original volume, and obtain a slow-release powder after spray drying;

[0041] (3) Mix the slow-release powder with cellulose acetate and carboxymethyl cellulose at a weight ratio of 1:2.5:0.8, add an appropriate amount of water and use an extruder for secondary granulation, and obtain solid fragrance beads after drying.

Embodiment 2

[0043] (1) Add 5g of soybean lecithin to 20 times the weight of absolute ethanol, stir at 45°C, and the stirring speed is 1000r / min. After the dissolution is complete, slowly add 100g of peppermint oil and 50g of 20% Tween 80 solution, and continue stirring 45min, obtain emulsion;

[0044] (2) Add 250g of ethyl cellulose (70mPa·s) to the emulsion, keep stirring at 45°C for 30min at a stirring speed of 800r / min, let cool and add 200g of hydroxypropylmethylcellulose (4000mPa·s ), continue to stir for 2h, then concentrate the solution in vacuum to 1 / 4 of the original volume, and obtain a slow-release powder after spray drying;

[0045] (3) Mix the slow-release powder with cellulose acetate and carboxymethyl cellulose at a weight ratio of 1:2.5:0.8, add an appropriate amount of water and use an extruder for secondary granulation, and obtain solid fragrance beads after drying.

Embodiment 3

[0047](1) Add 8g of egg yolk lecithin to 20 times the weight of absolute ethanol, stir at 50°C, and the stirring speed is 1000r / min, after the dissolution is complete, slowly add 100g of peppermint oil and 100g of 20% Tween 80 solution, and continue stirring 50min, obtain emulsion;

[0048] (2) Add 300g of ethyl cellulose (55mPa·s) to the emulsion, keep stirring at 45°C for 30min at a stirring speed of 800r / min, let cool and add 150g of hydroxypropylmethylcellulose (5000mPa·s ), continue to stir for 2h, then concentrate the solution in vacuum to one-third of the original volume, and obtain a slow-release powder after spray drying;

[0049] (3) Mix the slow-release powder with cellulose acetate and carboxymethyl cellulose at a weight ratio of 1:2.5:0.8, add an appropriate amount of water and use an extruder for secondary granulation, and obtain solid fragrance beads after drying.

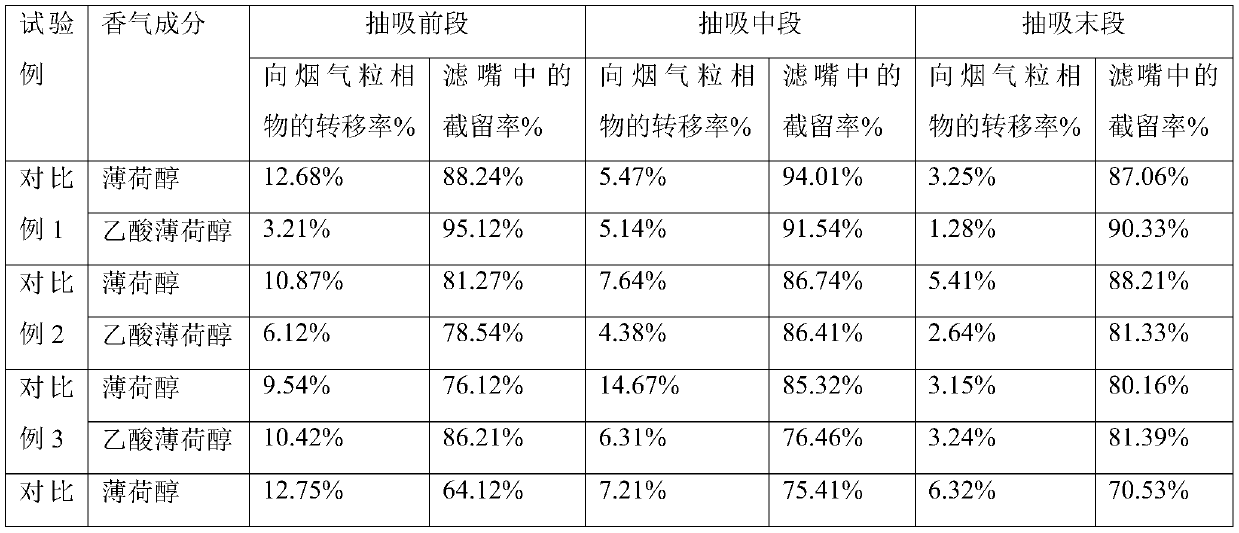

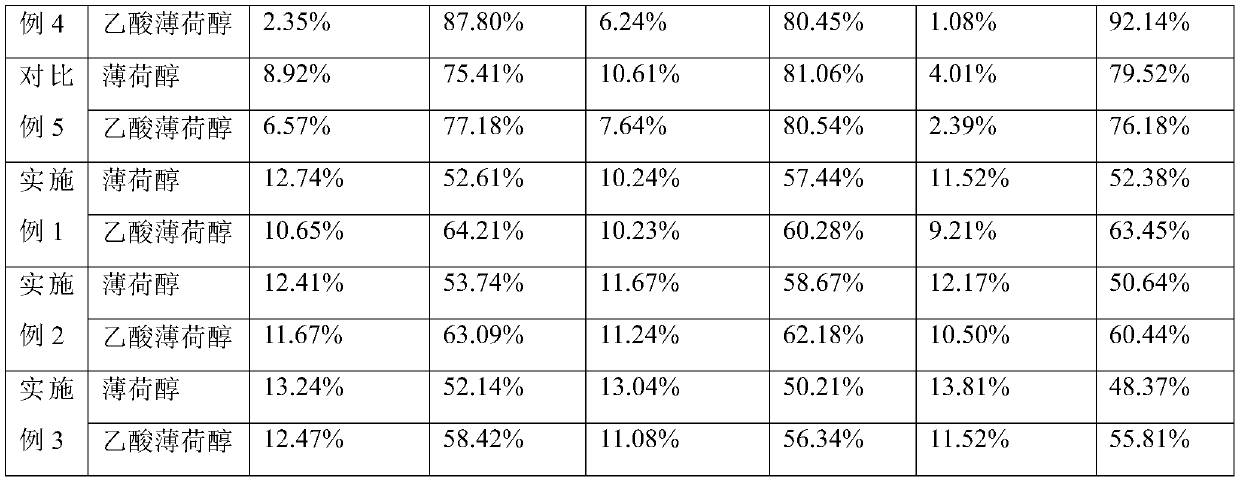

[0050] Weigh the same weight of solid incense beads prepared in Comparative Examples and Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com