Sweater fabric and production process thereof

A production process and fabric technology, applied in the field of textile fabrics, can solve the problems of skin discomfort, reduced fabric comfort, complex production process, etc., and achieve the effects of improving comfort, good air permeability, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

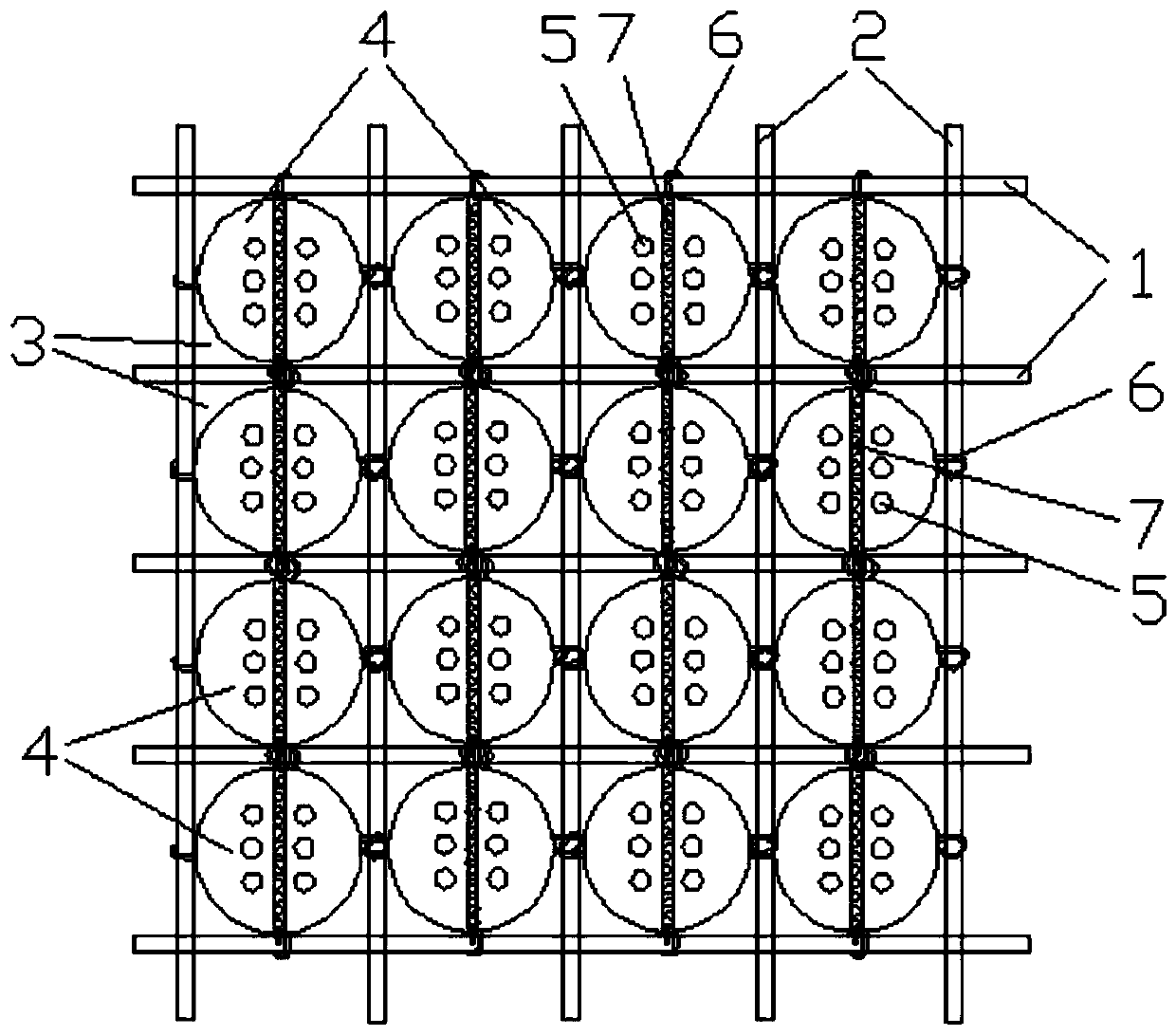

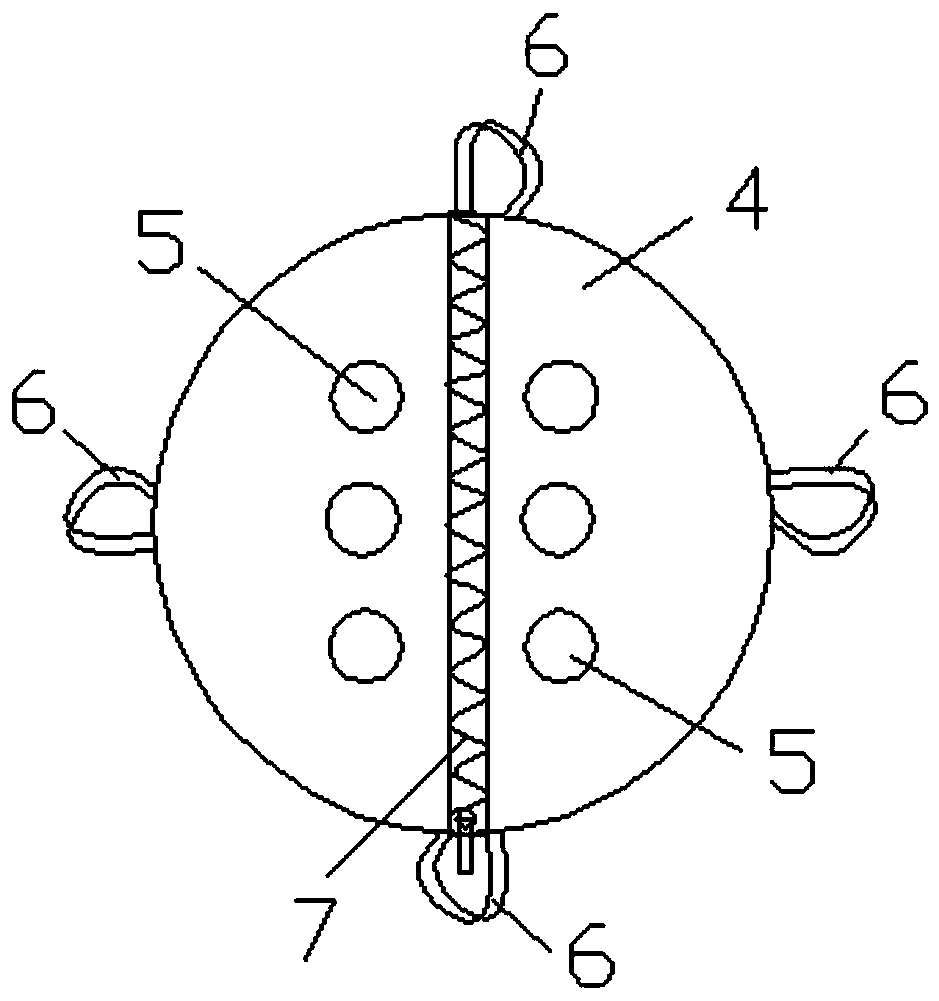

[0038] Such as figure 1 As shown, a number of first yarns 1 and a number of second yarns 2 are braided horizontally and vertically to form a fabric body. In this weaving method, the first yarn 1 is a transverse yarn, the second yarn 2 is a longitudinal yarn, and the first yarn 1 and the second yarn 2 are criss-crossed to form a gauze, and a plurality of yarns are distributed in the gauze. square grid, a plurality of balls 4 are respectively distributed in the square grid in the gauze net, and the corresponding first yarn 1 and second yarn 2 pass through the collar 6 on the ball 4 respectively, the weaving is convenient and fast, and the overall The structure is beautiful and generous.

Embodiment 2

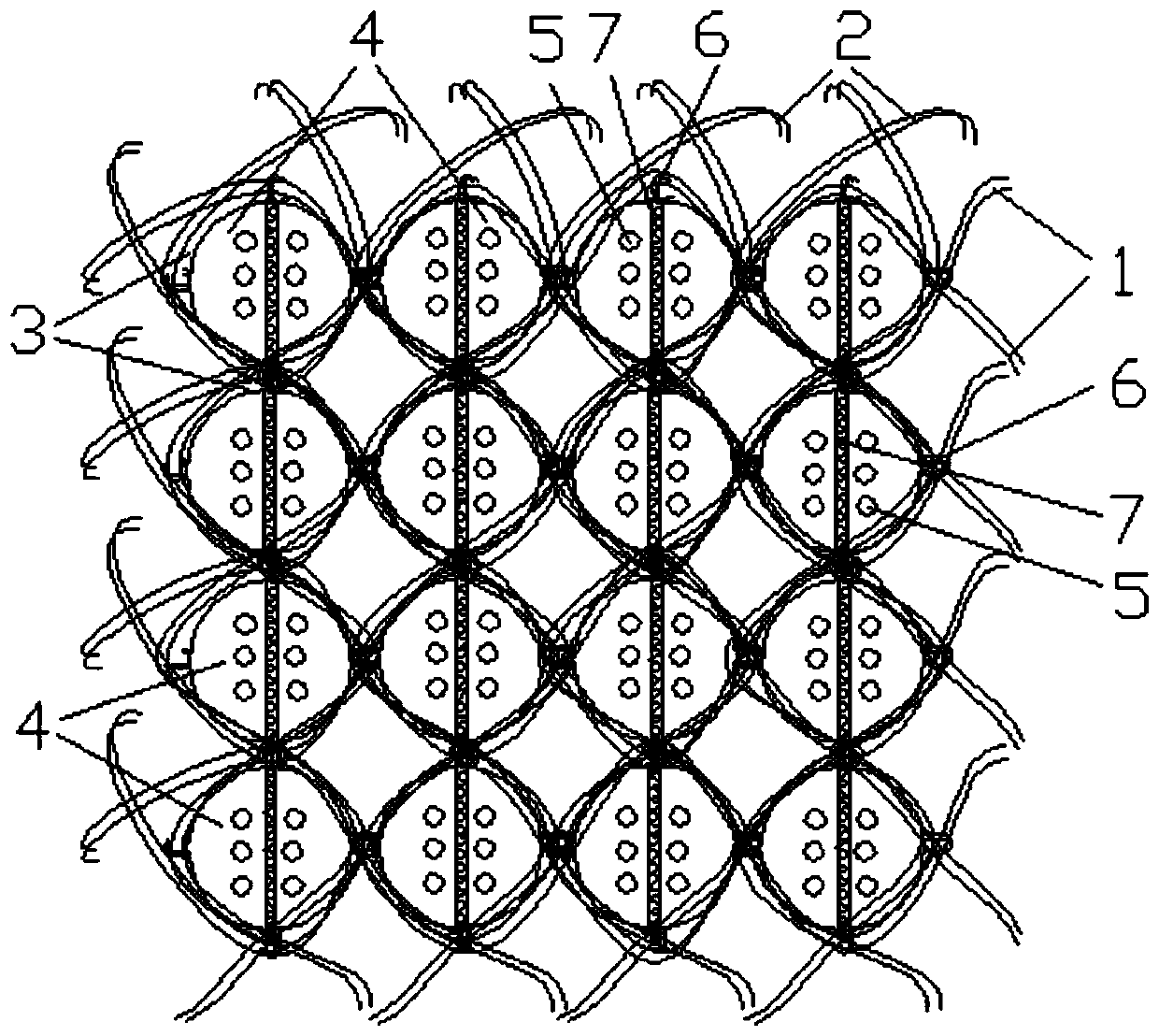

[0040] Such as figure 2 As shown, a number of first yarns 1 and a number of second yarns 2 are cross-woven into a fabric body in a wave shape. In this weaving method, the first yarn 1 and the second yarn 2 are criss-crossed to form a gauze, and a plurality of oval grids are distributed in the gauze, and a plurality of balls 4 are respectively distributed in the oval grids in the gauze. In the grid, corresponding first yarn 1 and second yarn 2 pass through the collar 6 on the ball 4 at the same time, the weaving is convenient and fast, and the overall structure is beautiful and generous. In addition, the diameter of the ball 4 is small, generally 0.5-1 cm, so it will not affect the overall warmth retention effect of the final sweater.

[0041] It should be noted that the ball 4 in the second embodiment can be figure 2 The manner shown is distributed in gauze, and it is also possible to distribute a ball 4 in each elliptical grid. In comparison, the weaving method in the se...

Embodiment 3

[0054] The specific processing steps for processing the black pure wool double-sided jacquard fabric suitable for making coats with a yarn count of 1 / 46NM black pure wool slub dyed yarn are as follows:

[0055] (1) Get the black pure wool slub dyed yarn that the yarn count is 1 / 46NM and weave black pure wool double-sided jacquard gray fabric on the circular knitting machine;

[0056] (2) Put the gray cloth into the overflow tank, control the weight bath ratio of wool gray cloth and water to 1:8, then add degreaser RC9 1.5g / L into the water, heat up to 50°C, keep warm for 20 minutes, drain, and use Rinse the gray cloth with clean water, then add water to the gray cloth again, control the weight-to-bath ratio of gray cloth to water to 1:8, then add color-fixing agent TF-506 3g / L into the water, raise the temperature to 50°C, keep it warm for 20 minutes, and drain , dehydration;

[0057] (3) Add water to the softening machine, control the weight-to-bath ratio of gray cloth and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com