Self-resetting corrugated variable friction damper

A variable friction, self-resetting technology, applied in building components, earthquake resistance, building types, etc., can solve the problems of shape memory alloy performance greatly affected by temperature, insufficient elastic deformation ability of prestressed steel bars, etc., achieving good popularization and cost. Low, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

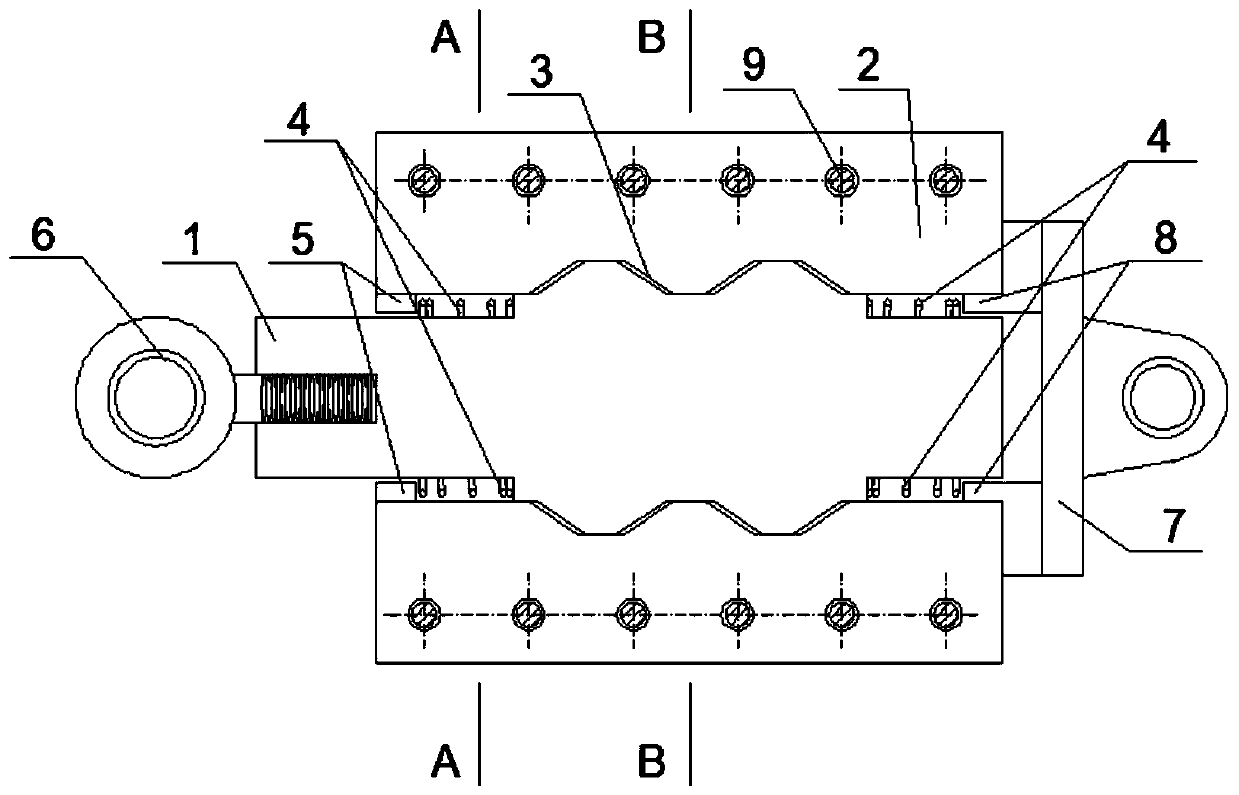

[0023] Such as Figure 1 to Figure 3 As shown, the present invention provides a self-resetting corrugated variable friction damper, which uses metal friction to dissipate energy, has good durability, allows large displacement deformation, and can withstand a large ultimate load; High-performance springs are less affected by the environment and can achieve self-resetting well.

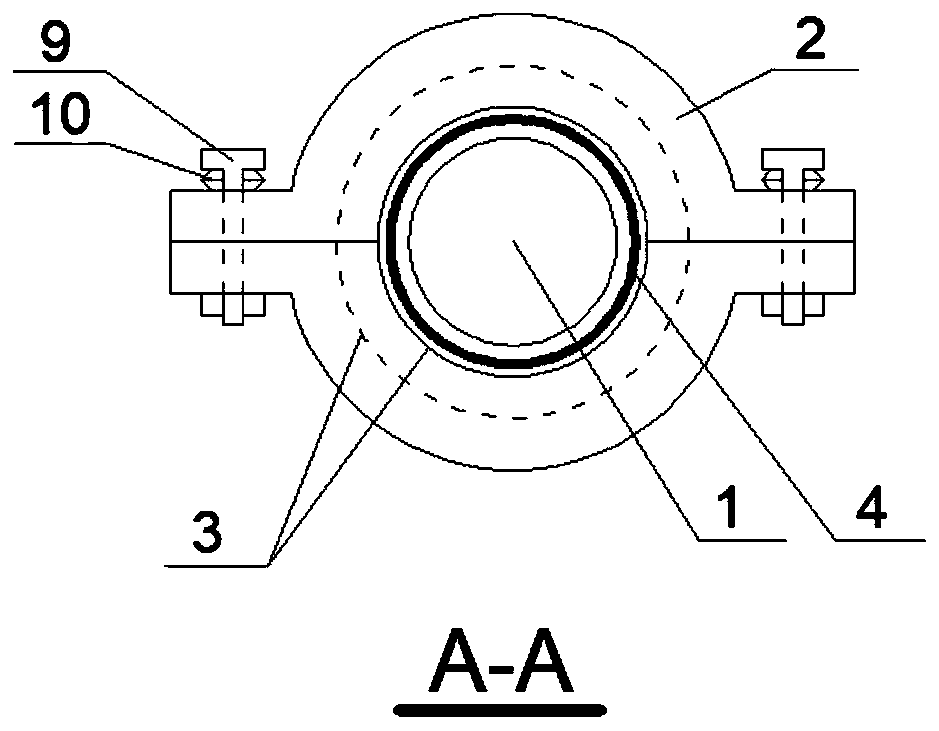

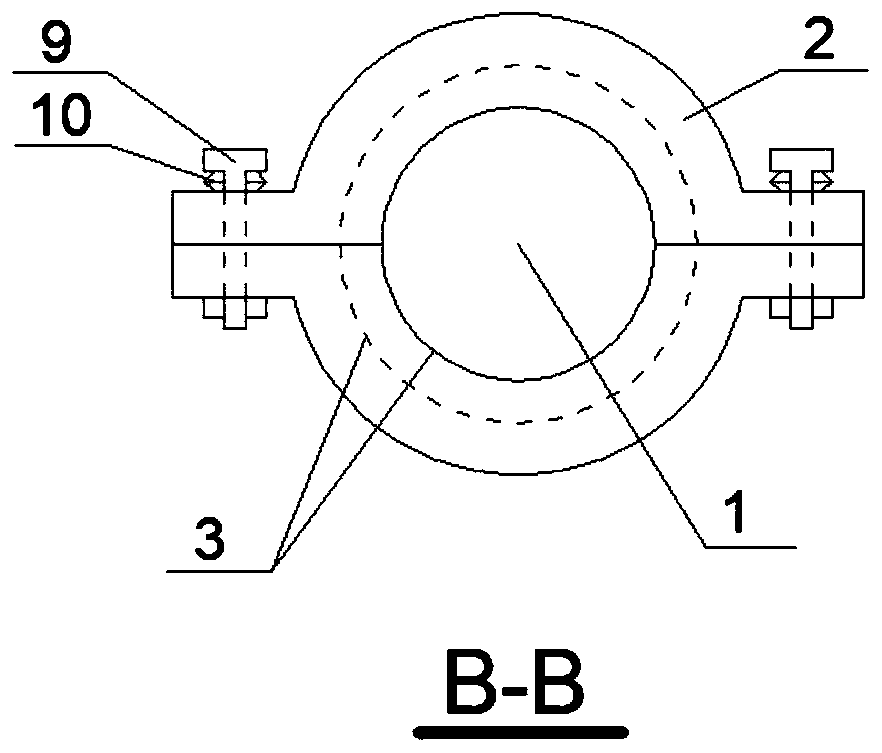

[0024] The structure of the self-resetting corrugated variable friction damper of the present invention is as follows: figure 1 as shown, figure 2 and image 3 respectively figure 1 Middle A-A profile and B-B profile. The present invention mainly includes an inner tube 1, an outer tube 2, a friction assembly 3, a coil spring 4, a first flange baffle 5, a ring joint 6, an end cover 7, a second flange baffle 8, high-strength bolts 9, Belleville spring 10.

[0025] The inner tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com