Quasi-optical microcavity structure solar spectrum selective absorption coating and preparation method thereof

An optical microcavity and absorbing coating technology, which is applied in coatings, solar thermal power generation, metal material coating technology, etc., can solve the problems of single research, influence of coating optical properties, emissivity increase, etc., and achieve solar absorption rate High, easy to adjust the spectral absorption range, good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1QOM quasi-optical microcavity base selective absorption coating

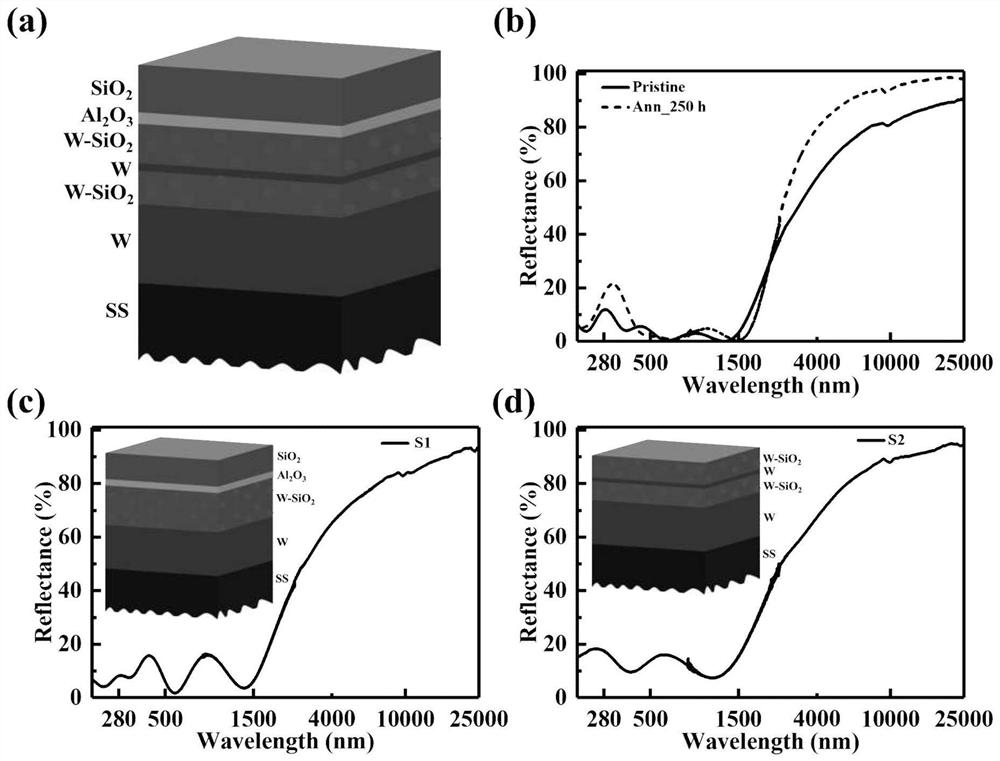

[0043] A high-temperature stable quasi-optical microcavity structure solar spectrum selective absorption coating, including three parts: from bottom to top, there are metal infrared reflective layer, quasi-optical microcavity absorber, and optical anti-reflection layer, see 1(a) as shown,

[0044] Among them, the quasi-optical microcavity absorber is composed of a cermet 1-metal-cermet 2 structure,

[0045] The metal is metal W, and the cermet is W-SiO 2 Cermet, dielectric Al for optical antireflection layer 2 o 3 and SiO 2 .

[0046] Among them, W infrared reflective layer is about 50-150nm, W-SiO 2 Cermet 1 is about 30-60nm, the middle metal W layer is about 3-15nm, W-SiO 2 Cermet 2 is about 45-65nm, Al 2 o 3 Optical anti-reflection layer 1 is about 10-30nm, SiO 2 The thickness of the optical anti-reflection layer 2 is about 45-70nm. Volume ratio of cermet composition (W:SiO 2 )...

Embodiment 2

[0063] Embodiment 2 performance detection comparison

[0064] Under the condition that only the normal incidence is considered, the calculation formula of the absorption rate can be simplified as:

[0065]

[0066] Among them, λ is the wavelength; I is the standard solar spectrum (AM 1.5); R λ is the emission spectrum of the corresponding wavelength. R λ It can be measured by ultraviolet-visible-near-infrared spectrophotometer and Fourier transform infrared spectrometer. Similarly, under the condition of only normal incidence, the thermal emissivity calculation formula can be simplified to the following formula:

[0067]

[0068] Among them, M λ is the blackbody radiation intensity at the corresponding wavelength.

[0069] The light-to-heat conversion efficiency of the solar spectrum selective absorbing coating is then calculated according to the absorptivity α and thermal emissivity ε. Photothermal conversion efficiency η Thermal Follow the formula below:

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap