Current sensor and method for measuring an electric current

A technology of current sensor and resistance measurement, applied in the direction of measuring current/voltage, measuring electricity, components of electrical measuring instruments, etc., can solve the problems of deviation temperature and long transmission path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

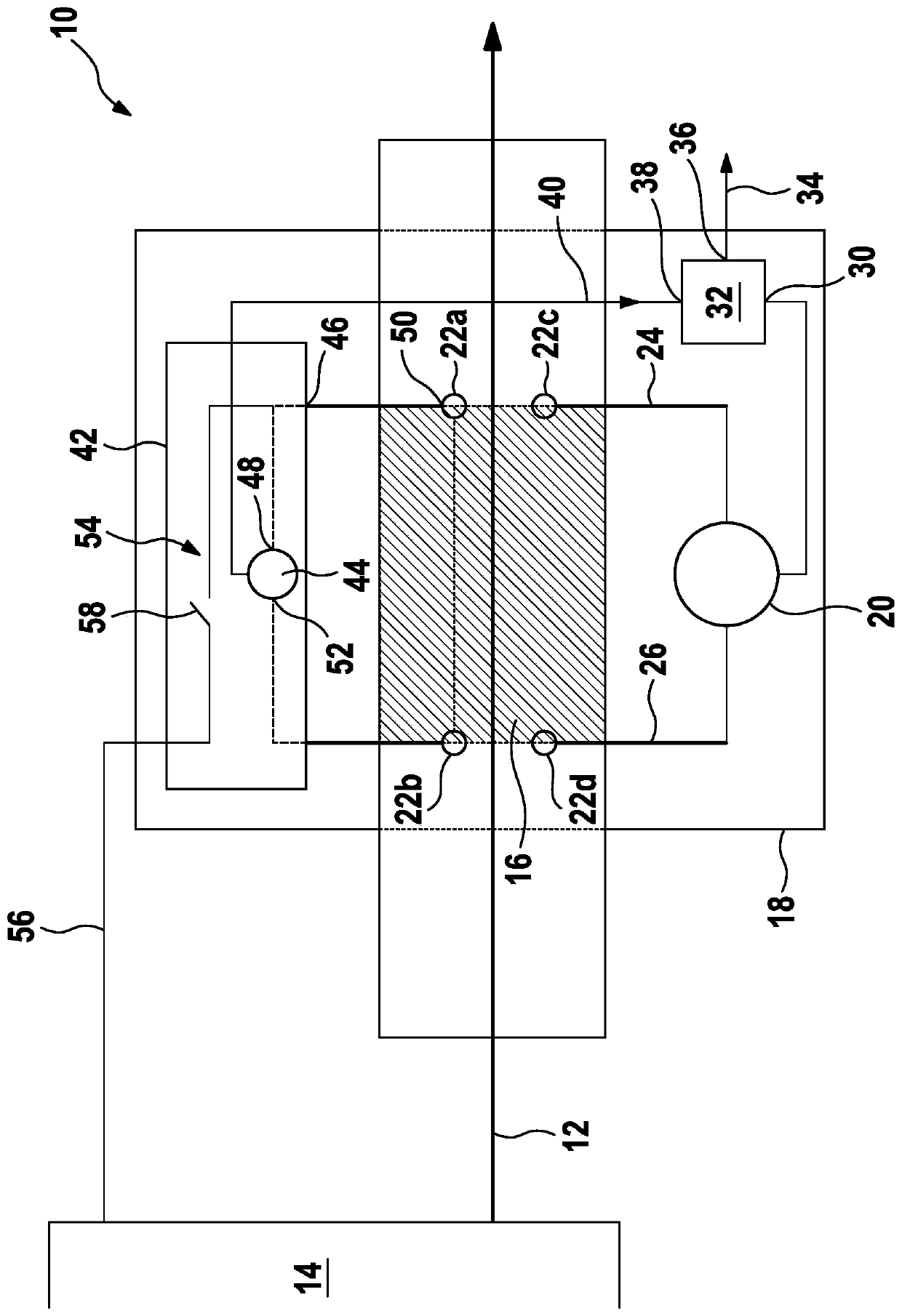

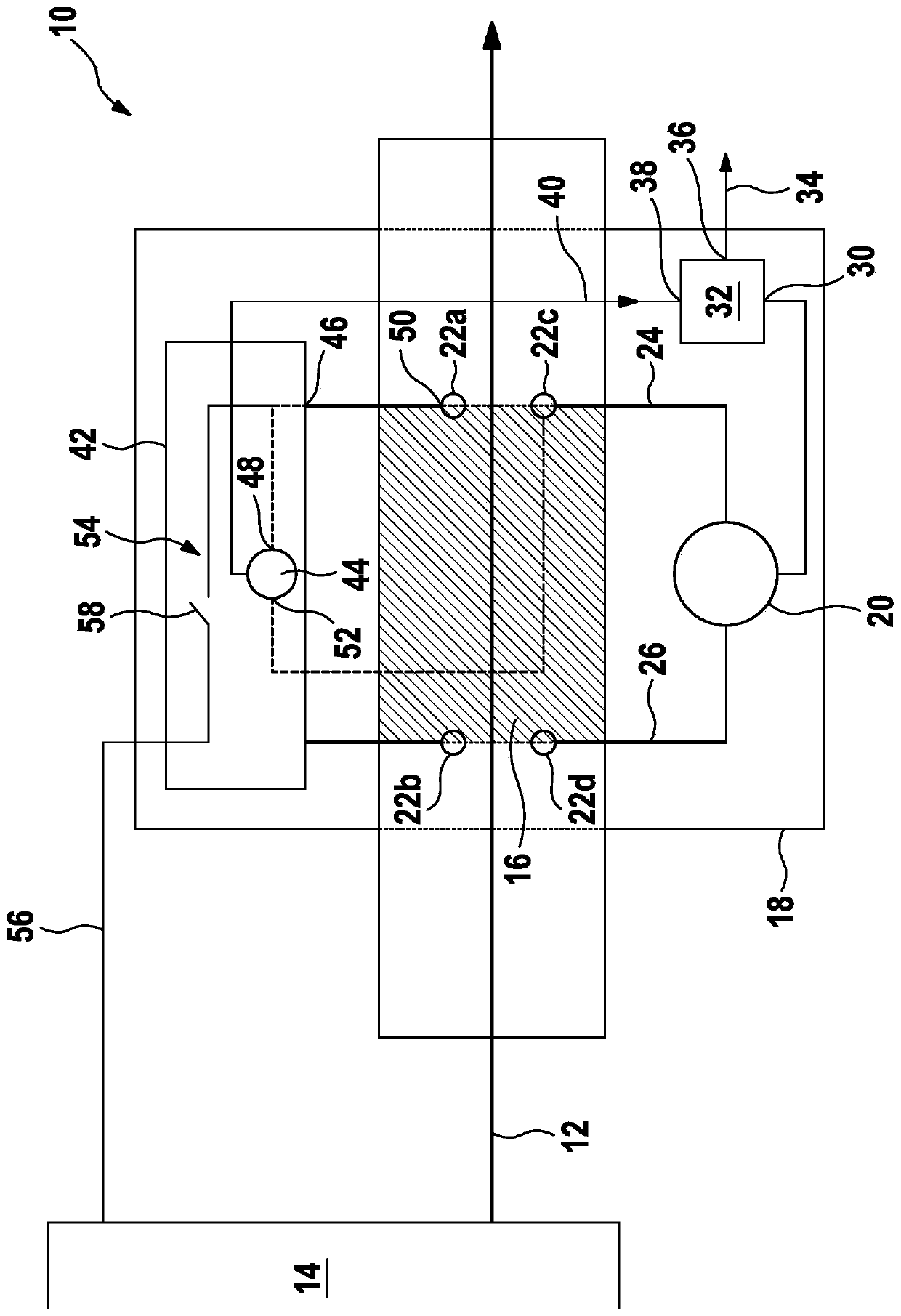

[0033] figure 1 A current sensor 10 for measuring a load current 12 of a battery 14 is shown. The battery 14 is, for example, a vehicle battery, the state of charge or state of health of which is intended to be defined by measuring the load current 12 .

[0034] The current sensor 10 has a measuring resistor 16 which can be electrically connected to the battery 14 such that the load current 12 of the battery 14 flows entirely via the measuring resistor 16 . Furthermore, current sensor 10 has a circuit carrier 18 on which measuring circuit 20 is arranged. The circuit carrier 18 is held on the measuring resistor 16 using a plurality of fixing pins 22a, 22b, 22c, 22d.

[0035] The measuring circuit 20 has a first measuring contact 24 and a second measuring contact 26, which are electrically connected to the measuring resistor 16 by means of corresponding fixing pins 22c, 22d, wherein the measuring contacts 24, 26 are at The current direction is electrically connected to the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com