A multi-working-condition design method of a gas-liquid separator for a water-activated battery

A technology of gas-liquid separator and design method, which is applied in the direction of instrumentation, calculation, and electrical digital data processing, etc., which can solve the problems of gas-liquid separator separation efficiency, discharge out of the cabin, and adapt to the small flow range, etc., to achieve good gas-liquid Separation performance, complete gas-liquid separation, and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

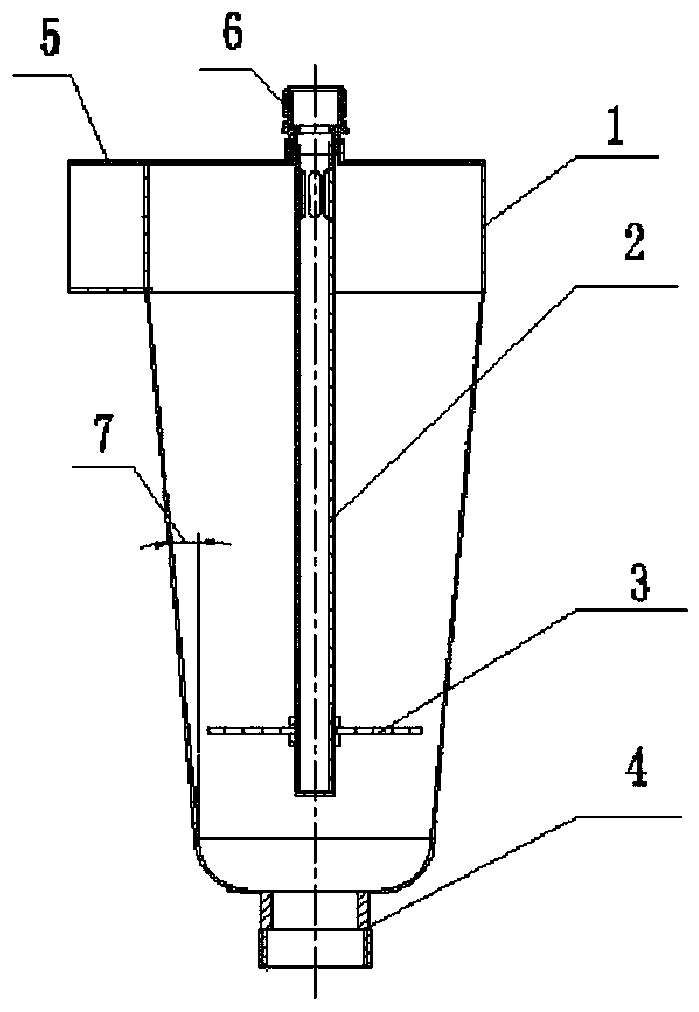

Image

Examples

Embodiment

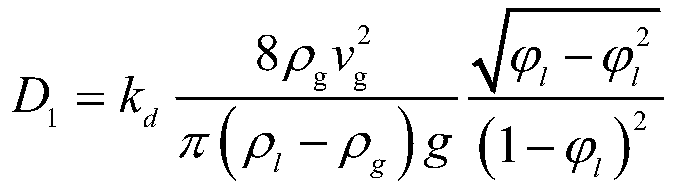

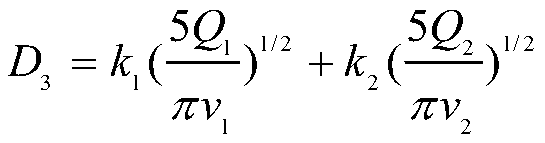

[0087] Among them, the cone angle θ is 6°-10°, the diameter coefficient kd is 0.3-0.5, the low-speed flow coefficient k1 is 1.5-1.7, the high-speed flow coefficient k2 is 2.4-2.65, the length-to-diameter ratio λ is 1.6-1.85, and the value range The effects are similar, in order to better explain the problem, select the value to calculate the corresponding result.

[0088] The design high-speed working condition has a liquid inlet flow rate of 0.0069m 3 / s, the high-speed liquid phase volume fraction is 0.85, and the low-speed working condition feed liquid flow is 0.0056m 3 / s, the volume fraction of the low-speed liquid phase is 0.89, and the density of the transported liquid is 1210kg / m 3 , the gas density is 1.29kg / m 3 , the design high-speed gas phase velocity should not be greater than 5.5m / s.

[0089] (1) According to the design requirements, calculate the main parameters of the gas-liquid separator, and select the diameter coefficient k d is 0.35, the high-speed gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com