A transmission welding gear strength and fatigue life calculation method

A technology for welding gears and fatigue life, applied in computing, instrumentation, electrical and digital data processing, etc., can solve the problem that the actual life of welding gears varies greatly, and achieve the effect of avoiding repeated research and development, saving social resources, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

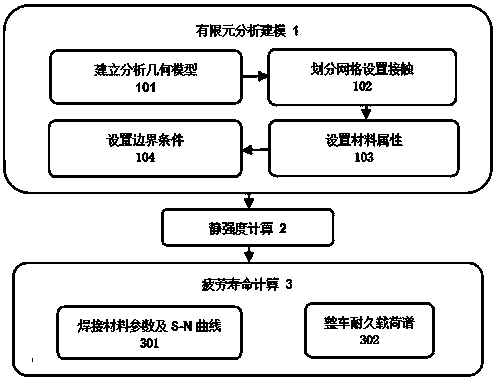

[0014] The present invention will be further described in conjunction with accompanying drawing and embodiment now. see Figure 1 to Figure 5 , a method for calculating the strength and fatigue life of transmission welded gears, including finite element analysis modeling 1, static strength calculation 2 and fatigue life calculation 3:

[0015] The first part, finite element analysis modeling 1, is completed by establishing an analytical geometric model 101 , dividing the network and setting contacts 102 , setting material properties 103 and setting boundary conditions 104 .

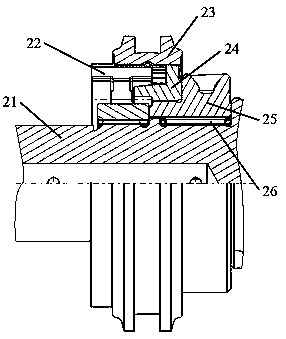

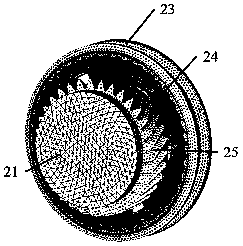

[0016] First, establish an accurate geometric model of the transmission shaft 21, the synchronizer hub 22, the gear sleeve 23, the combined ring gear 24, the welding gear 25 and the needle bearing 26 (such as figure 2 As shown), the dimensional tolerance of the external spline on the transmission shaft 21 is taken as the maximum upper deviation, and the dimensional tolerance of the inner spline of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com