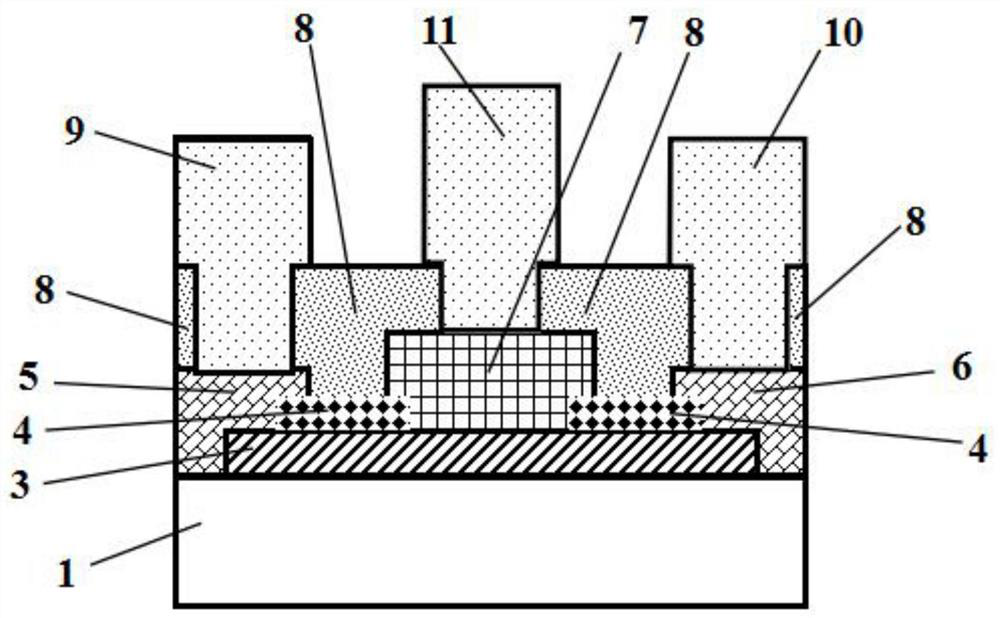

Preparation method of field effect transistor with n-type doped single crystal diamond field plate structure

A technology of field effect transistors and single crystal diamond, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as hard breakdown at the edge of electrodes, and achieve increased breakdown voltage, elimination of electric field concentration, and electric field evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1: removing the non-diamond phase on the surface of the diamond substrate 1 .

[0051] Such as figure 2 As shown, the diamond substrate 1 is cleaned using a standard acid-base cleaning process to remove the non-diamond phase on the surface, then the diamond substrate 1 is cleaned with alcohol, acetone, and deionized water, and the diamond substrate 1 is dried with nitrogen gas. .

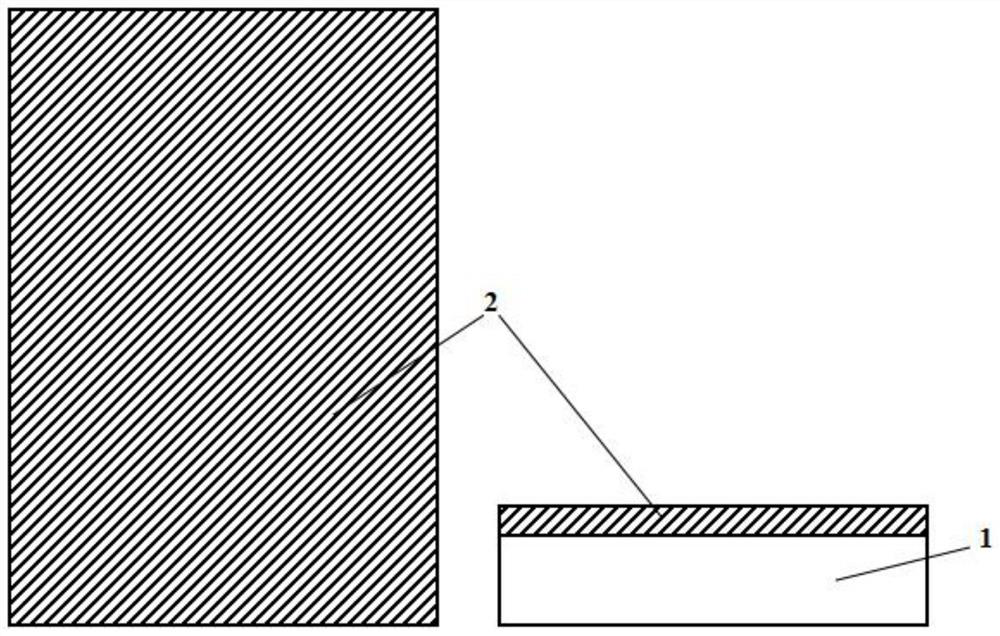

[0052] Step 2: growing a layer of n-type doped single crystal diamond epitaxial thin film 2 on the diamond substrate 1 .

[0053] A 1 μm-thick n-type doped single crystal diamond epitaxial film 2 was grown on a diamond substrate 1 by using microwave plasma chemical vapor deposition technology. The growth conditions were: power 1KW, chamber pressure 50 Torr, total gas flow 500 sccm, phosphine 20 sccm.

[0054] Step 3: Etching the n-type doped single crystal diamond epitaxial film 2 to form a mesa 3 .

[0055] Such as image 3 and Figure 4 As shown, a part of the n-type doped singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com