A Composite Pulse Power Supply for Ultrasonic EDM

A spark machining and compound pulse technology, applied in electric machining equipment, metal machining equipment, circuits, etc., can solve the problems of synchronization, inability to guarantee, inability to lock the phase difference between spark discharge pulse and ultrasonic vibration pulse, etc., to improve machining efficiency, Reasonable structure and the effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

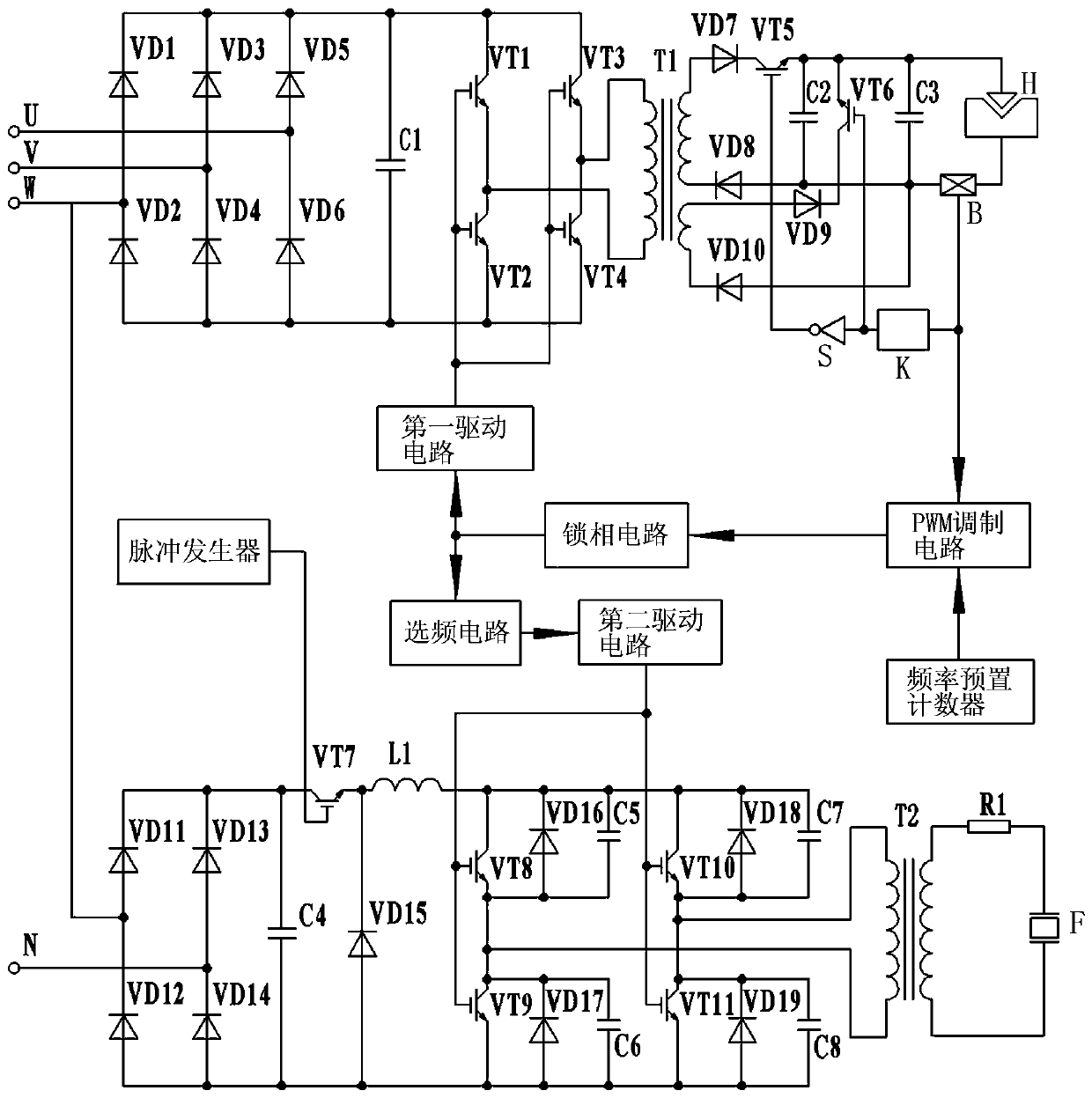

[0034] A composite pulse power supply for ultrasonic electric discharge machining, including a main circuit and a control circuit;

[0035] The main circuit includes a spark discharge pulse generating circuit and an ultrasonic vibration pulse generating circuit;

[0036] The spark discharge pulse generation circuit includes a first rectification and filtering module, a first DC chopper module, and a first voltage regulation discharge module;

[0037] The first rectification and filtering module includes a three-phase bridge rectification circuit composed of first to sixth diodes VD1~VD6, and a first capacitor C1;

[0038] The first DC chopper module includes first to fourth transistors VT1~VT4;

[0039] The first voltage regulating discharge module includes a pulse transformer T1, seventh to tenth diodes VD7~VD10, a fifth triode VT5, a sixth triode VT6, a second capacitor C2, a third capacitor C3, tools The discharge gap H between the electrode and the workpiece;

[0040] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com