Variable rotor speed helicopter-turboshaft engine integrated control method and device

A technology of turboshaft engine and rotor speed, which is applied to the power plant, aircraft parts, transportation and packaging of aircraft, etc. It can solve the problems of not having the ability to simulate the speed of variable rotor speed and being unable to apply closed-loop control, so as to improve the accuracy and reliability. Real-time performance, reducing overshoot and sag, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below through a preferred embodiment in conjunction with the accompanying drawings:

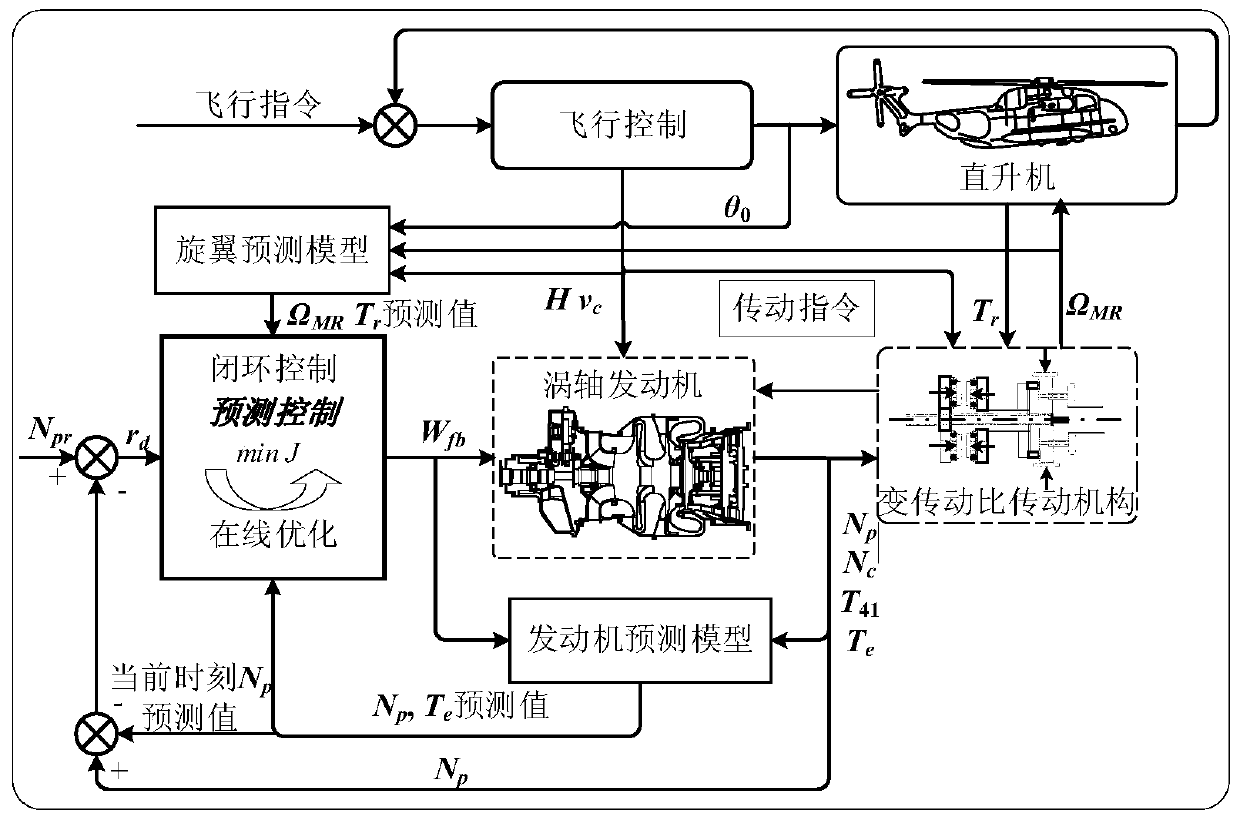

[0039] Such as figure 1 As shown, the variable rotor speed helicopter-turboshaft engine integrated control device in this embodiment is composed of three parts: a helicopter rotor prediction model, a turboshaft engine prediction model, and an online optimization unit. Both the turboshaft engine prediction model and the helicopter rotor prediction model are obtained offline. by figure 1 It can be seen that within a single simulation step, the turboshaft engine prediction model and the helicopter rotor prediction model respectively predict the output at the future time based on the input and pass it to the nonlinear model prediction controller (that is, the online optimization unit). The sequential quadratic programming (SQP) algorithm solves the objective function online, outputs the fuel control quantity, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com