Reverse assembly method of unexposed sleeve concrete prefabricated wallboard

A technology of prefabricated wall panels and assembly methods, applied in the direction of walls, structural elements, building components, etc., can solve the problems of unguaranteed connection quality and unsatisfactory proportion of sleeves, etc., and achieve fast speed, convenient construction, and labor-intensive small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

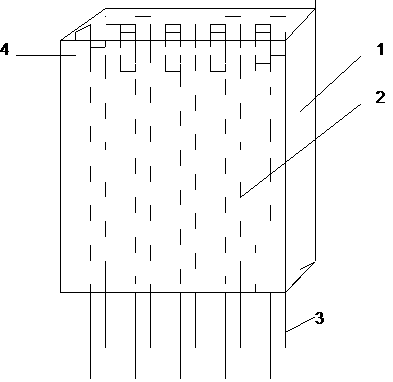

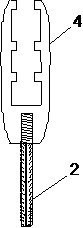

[0019] A reverse assembly method of a sleeveless concrete prefabricated wallboard, the sleeveless concrete prefabricated wallboard comprises a wallboard 1, a sleeve 4 is prefabricated in the top of the wallboard, and the upper opening of the sleeve is connected to the top surface of the wallboard It is flush, and the sleeve is in the form of no holes on the side and connecting pipes; the bottom of the sleeve is threadedly connected with the main reinforcement 2 prefabricated in the wall panel, and the lower end of the main reinforcement is exposed to the wall panel to form the anchor reinforcement 3 with the lower wall panel; when assembling, first anchor the The mortar is poured into the reinforcement hole of the sleeve, and then the anchoring steel bar at the lower end of the upper wallboard is inserted downward into the reinforcement hole of the sleeve; when the wallboard reinforcement is bound, the top of the sleeve is pressed against the mold. The length of the anchoring r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com