Deeper water jacket super slender ratio drill conductor marine installation technology

A water-resistant casing and installation process technology, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems affecting the construction efficiency of water-resistant casing, reduce the number of piles driven by piling hammers, and reduce construction risks and difficulties , Overcome the effect of turning over the length limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

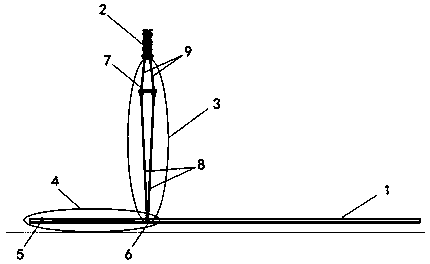

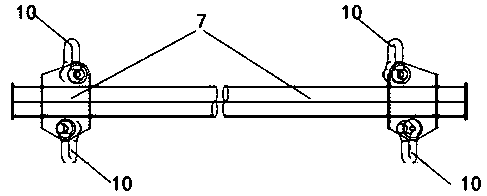

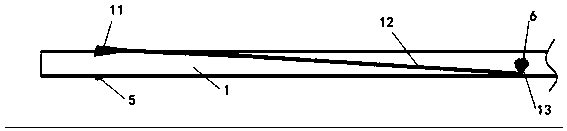

[0027] Such as Figure 1 to Figure 7 As shown, the present invention adopts the following installation steps:

[0028] Step 1: Install the second sling 4 on the ultra-slender water-resisting casing 1, such as figure 2 As shown; the second lifting sling 4 includes: two second lifting points 6 installed at the position of a quarter of the full length of the ultra-slender ratio water-resistant casing, respectively connected and installed on the two second lifting points 6 The two third snap rings 13 are installed on the two first hanging points 5 at the end of the ultra-slender water-resisting casing near the second hanging point 6 and 2 meters away from the end point, and are connected and installed on the two first hanging points respectively. Two second snap rings 11 on the point 5 and two third slings 12 respectively connected on the second snap ring 11 and the third snap ring 13, the two ends of the third sling 12 are respectively connected with a second The snap ring 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com