Two-stage compression adjustable dryness refrigeration system with ejector

A two-stage compression and refrigeration system technology, applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of low condensation efficiency of condensers, unfavorable equipment miniaturization, and low heat exchange efficiency, achieving simple structure and easy maintenance , Energy-saving and material-saving effect of space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

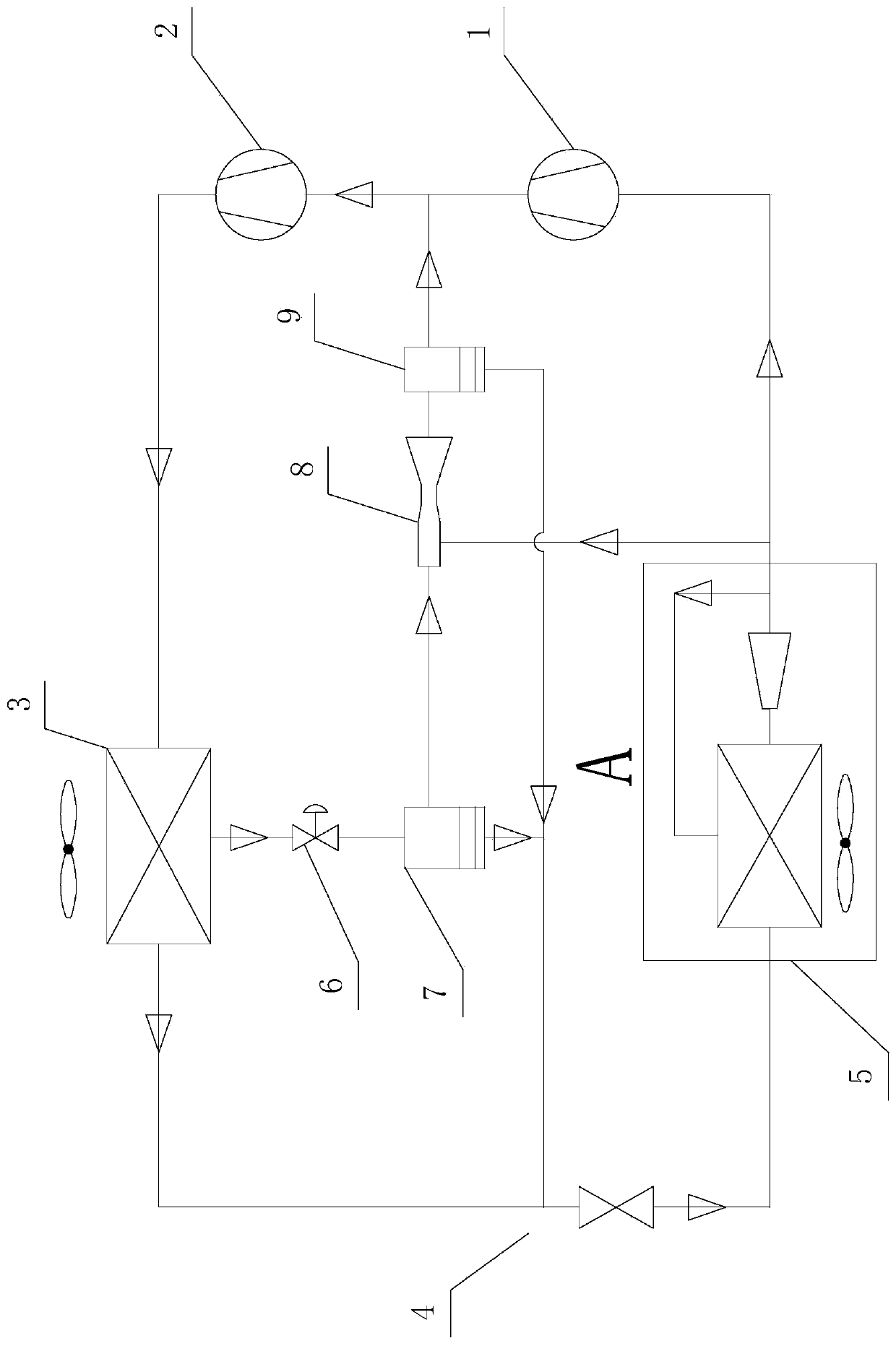

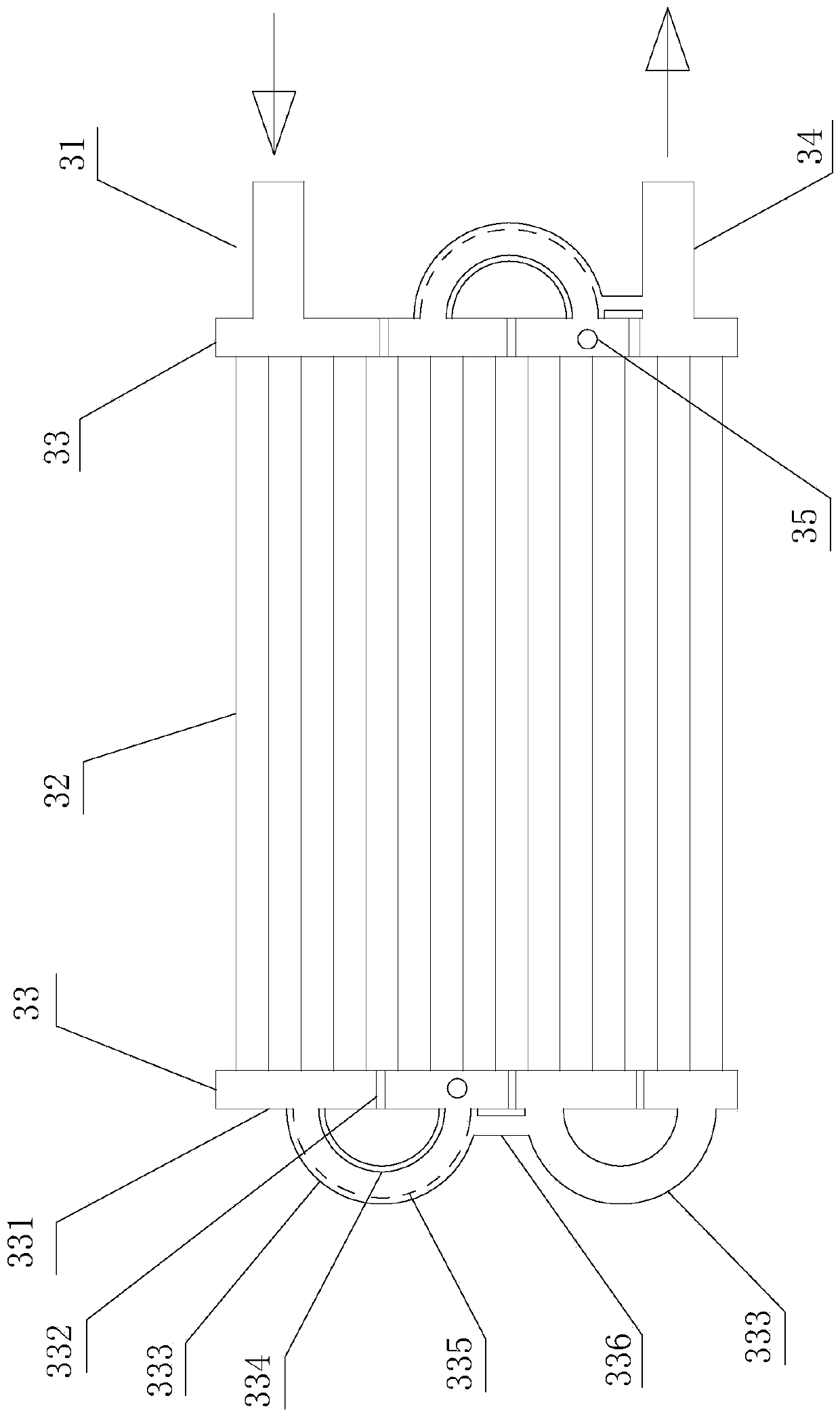

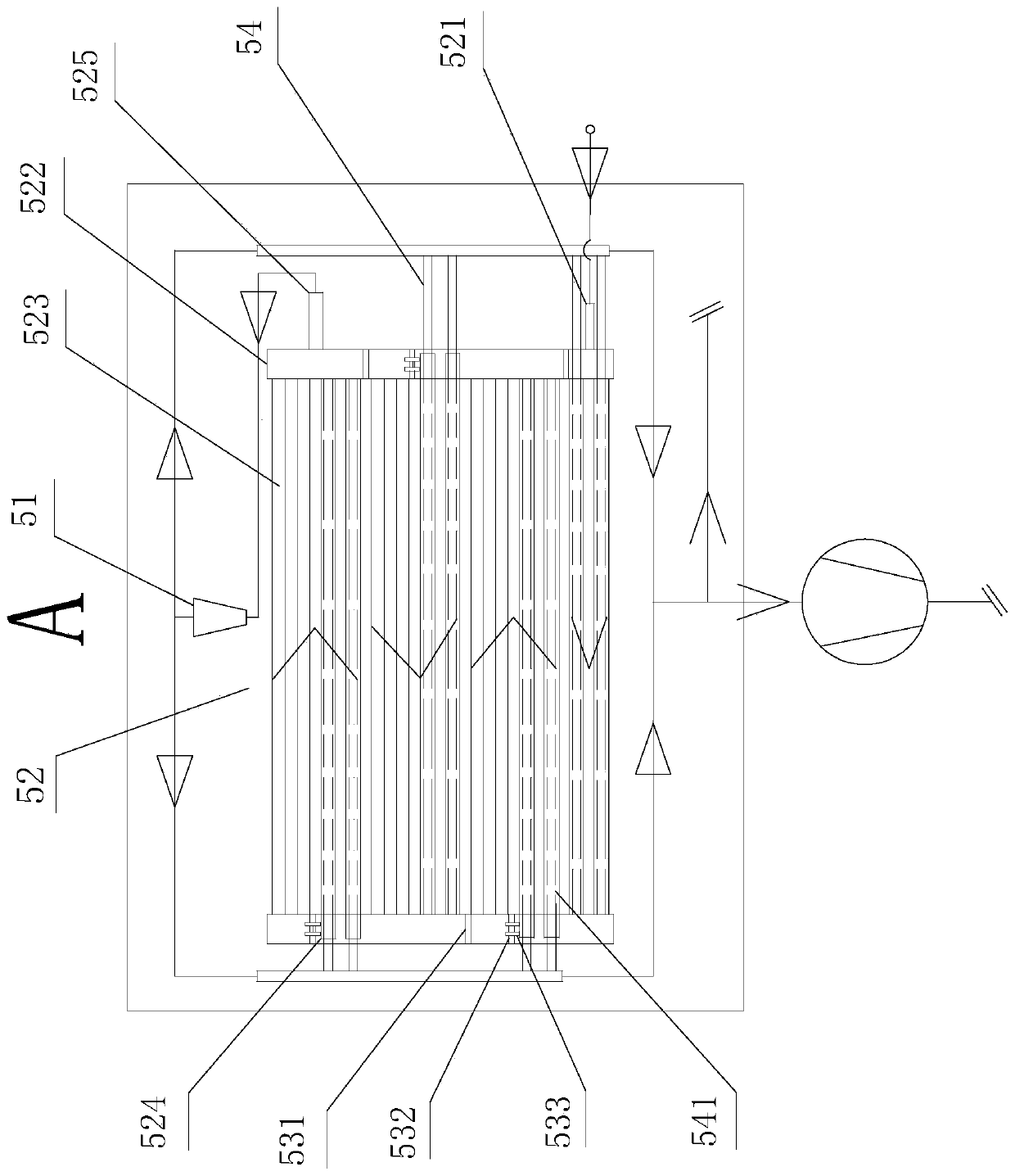

[0023] see Figure 1-Figure 4 , the two-stage compression adjustable dryness refrigeration system with ejector, including the main refrigeration cycle and injection module, the main refrigeration cycle includes the primary compressor 1, the secondary compressor 2, and the adjustable dryness condenser connected with the inlet and outlet in sequence Device 3, throttle valve 4, dryness adjustable evaporator device 5; the injection module includes an electronic valve 6, a gas-liquid separator I7, an injector 8 and a gas-liquid separator II9, wherein the inlet of the electronic valve 6 is connected to the The outlet of the dryness-adjustable condenser device 3 is connected, the outlet of the electronic valve 6 is connected with the inlet of the gas-liquid separator I7, and the outlet of the gas-liquid separator I7 is respectively connected with the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com