Device for realizing scour corrosion test of impeller of sea water pump

A technology of erosion corrosion and test equipment, which is applied in the directions of measuring equipment, weather resistance/light resistance/corrosion resistance, and wear resistance testing, etc., can solve the problems of untargeted measures for impeller protection, untargeted suggestions for impeller manufacturing and testing processes, Problems such as impeller running status cannot be simulated to achieve the effect of shortening the research cycle and reducing research costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments.

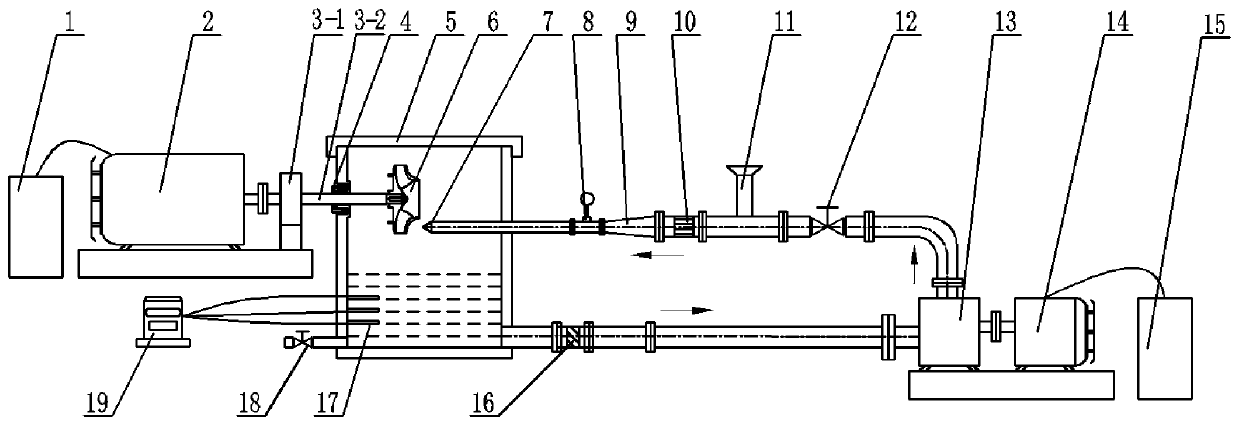

[0020] like figure 1 As shown in the figure, a device for realizing the erosion corrosion test of a seawater pump impeller is composed of an impeller installation module, a corrosion environment simulation module, an erosion condition simulation module, an acceleration module and corresponding auxiliary components.

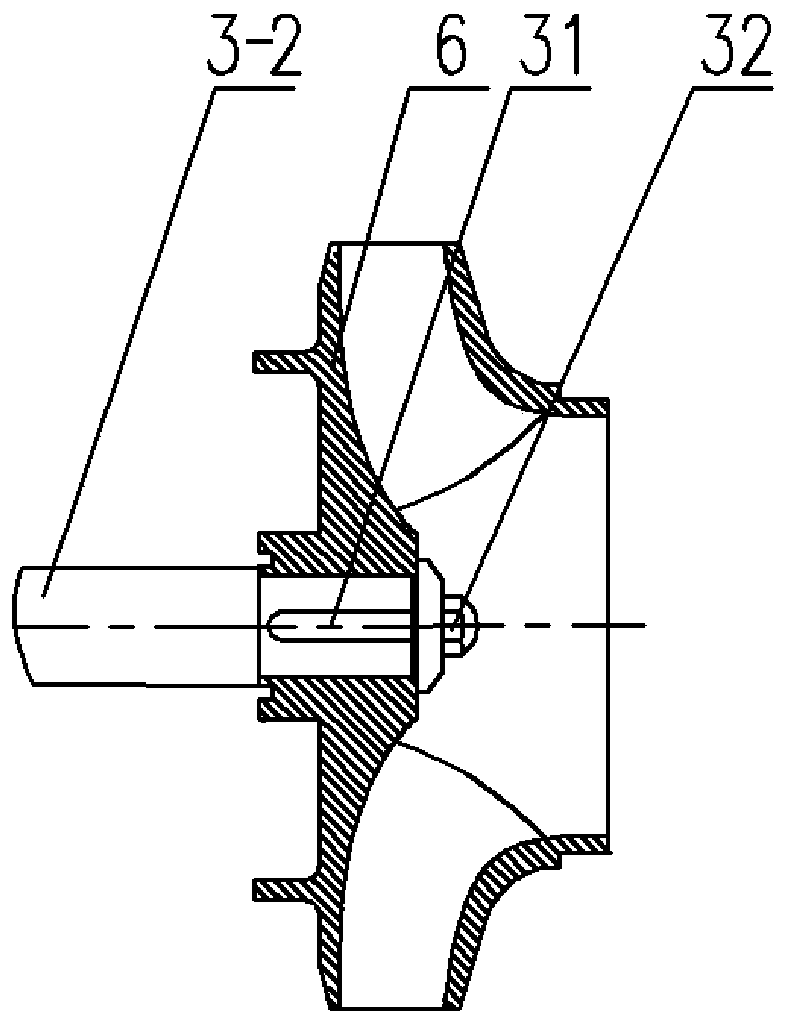

[0021] The impeller installation module includes a variable frequency drive 1, a variable frequency motor 2, an auxiliary support bearing seat 3-1, an installation shaft 3-2, and the like. The corrosive environment simulation module includes a sealing device 4, a water tank 5, a measured impeller 6, a flushing nozzle 7, a blowdown valve 18, and the like. The scouring condition simulation module includes a flow meter 8, a shrinking pipe section 9, a rectifying device 10, a sand input device 11, a regulating valve 12, a circulating water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com