Temperature and pressure controllable diffusion experimental device

A diffusion experiment, temperature and pressure technology, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as inability to react to diffusion factors, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

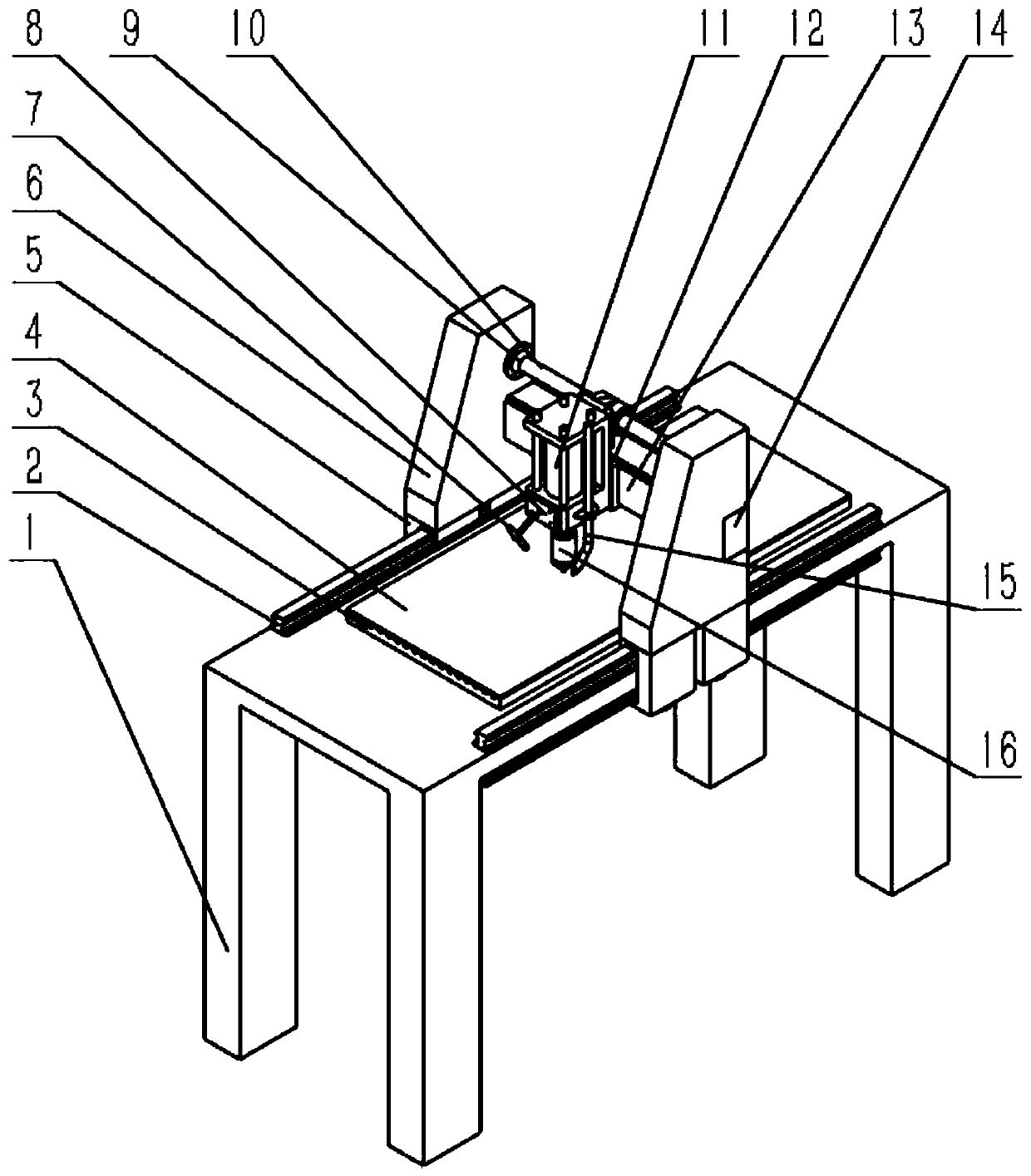

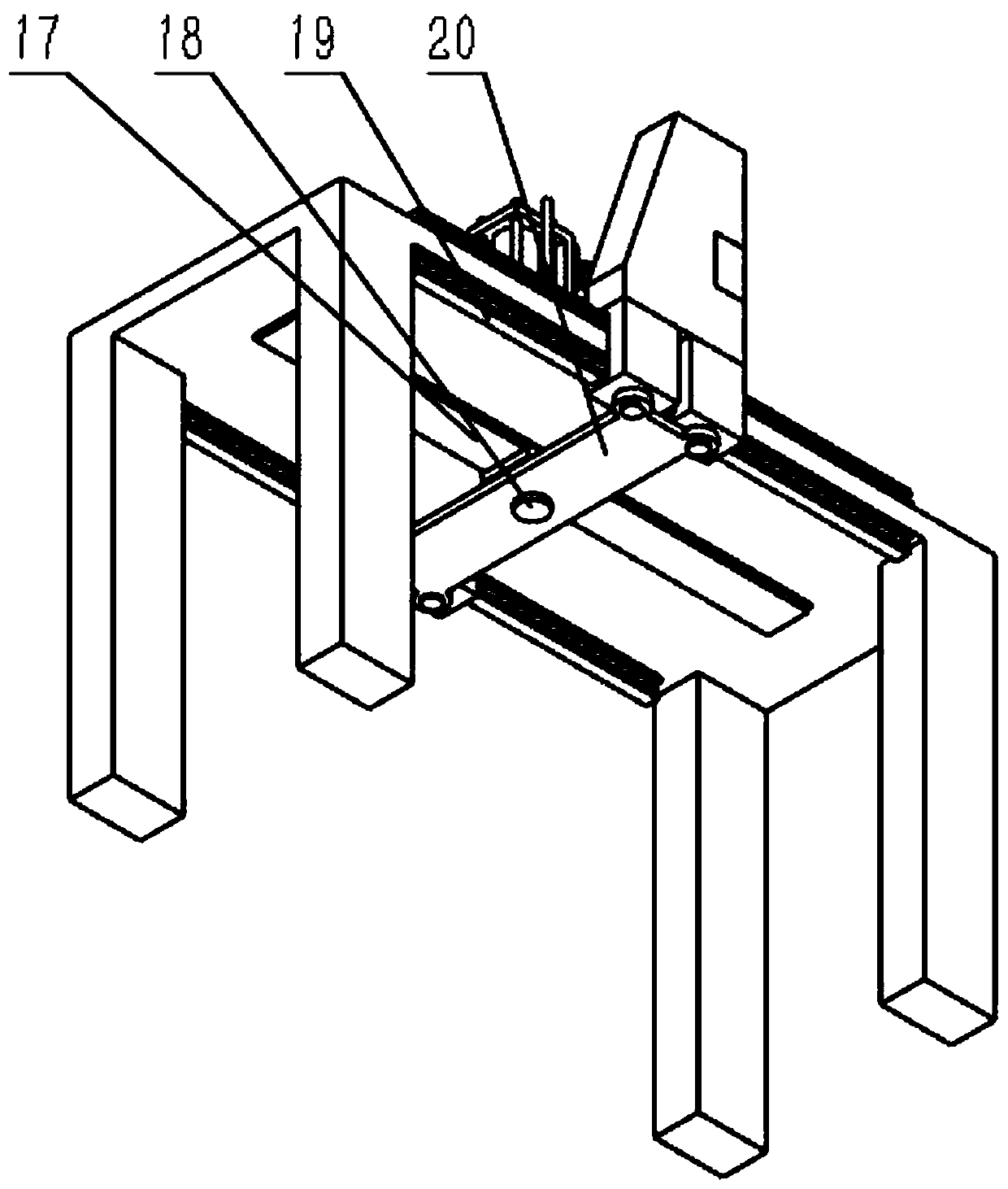

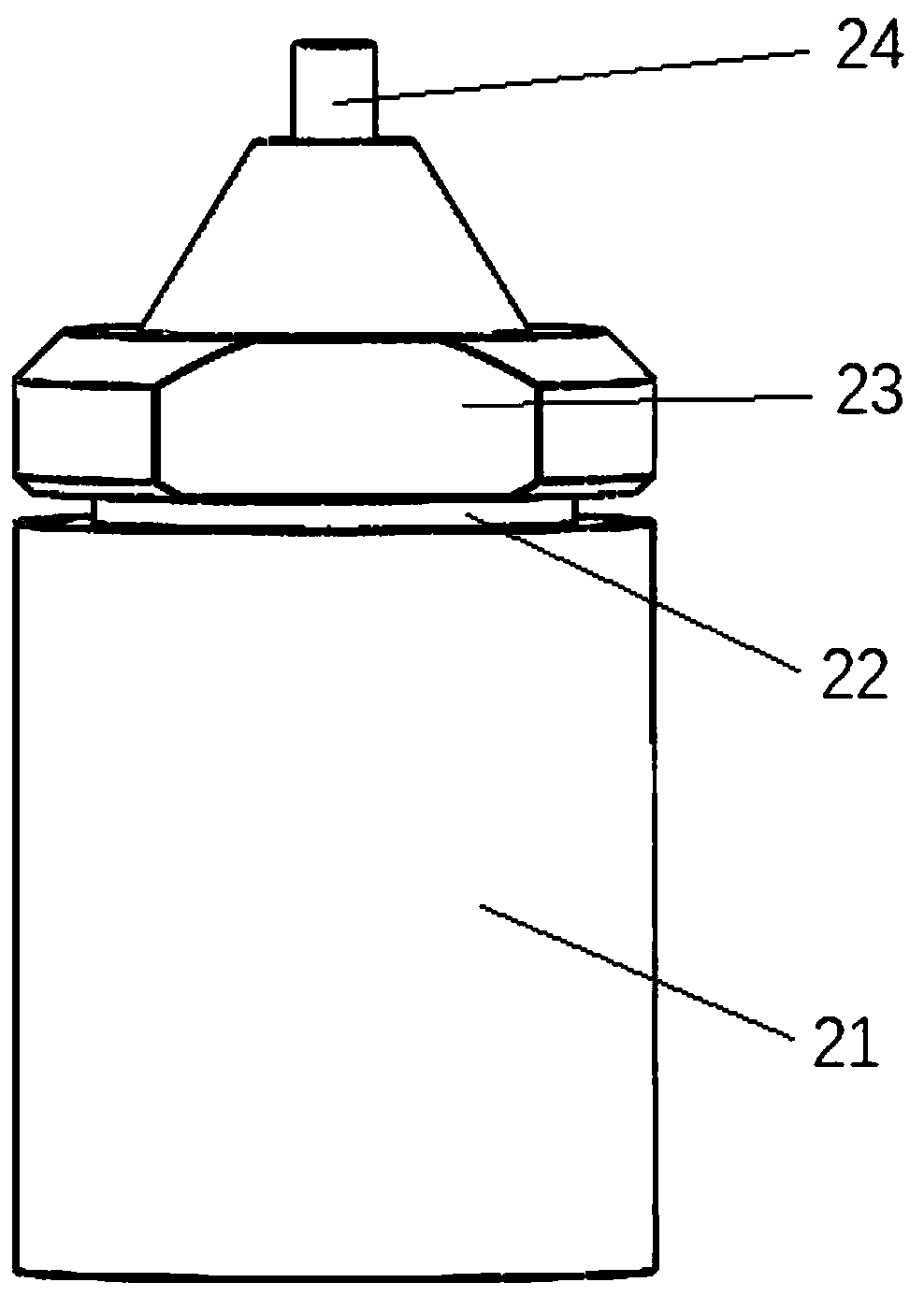

[0027] see Figure 1 to Figure 4 , the present invention provides a diffusion experimental device with controllable temperature and pressure, which provides an experimental device for studying the influencing factors of element diffusion in the cutting alloy of cemented carbide tools, especially provides a device that can reflect the actual diffusion factors and can accurately control the diffusion factor experimental setup.

[0028] In a specific embodiment, the temperature and pressure controllable diffusion experiment device includes a workbench 1, a transverse feeding device, a longitudinal feeding device, a pressure regulating device, a pressure measuring device, a tool holding device, a temperature regulating device and a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com