A performance and structure design and monitoring method for a high-medium pressure cylinder of an air-cooled high-parameter steam turbine

A structural design and steam turbine technology, applied in the field of steam turbines, can solve the problems of shortened life, insufficient power of air-cooled high-parameter steam turbines, and increased heat consumption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

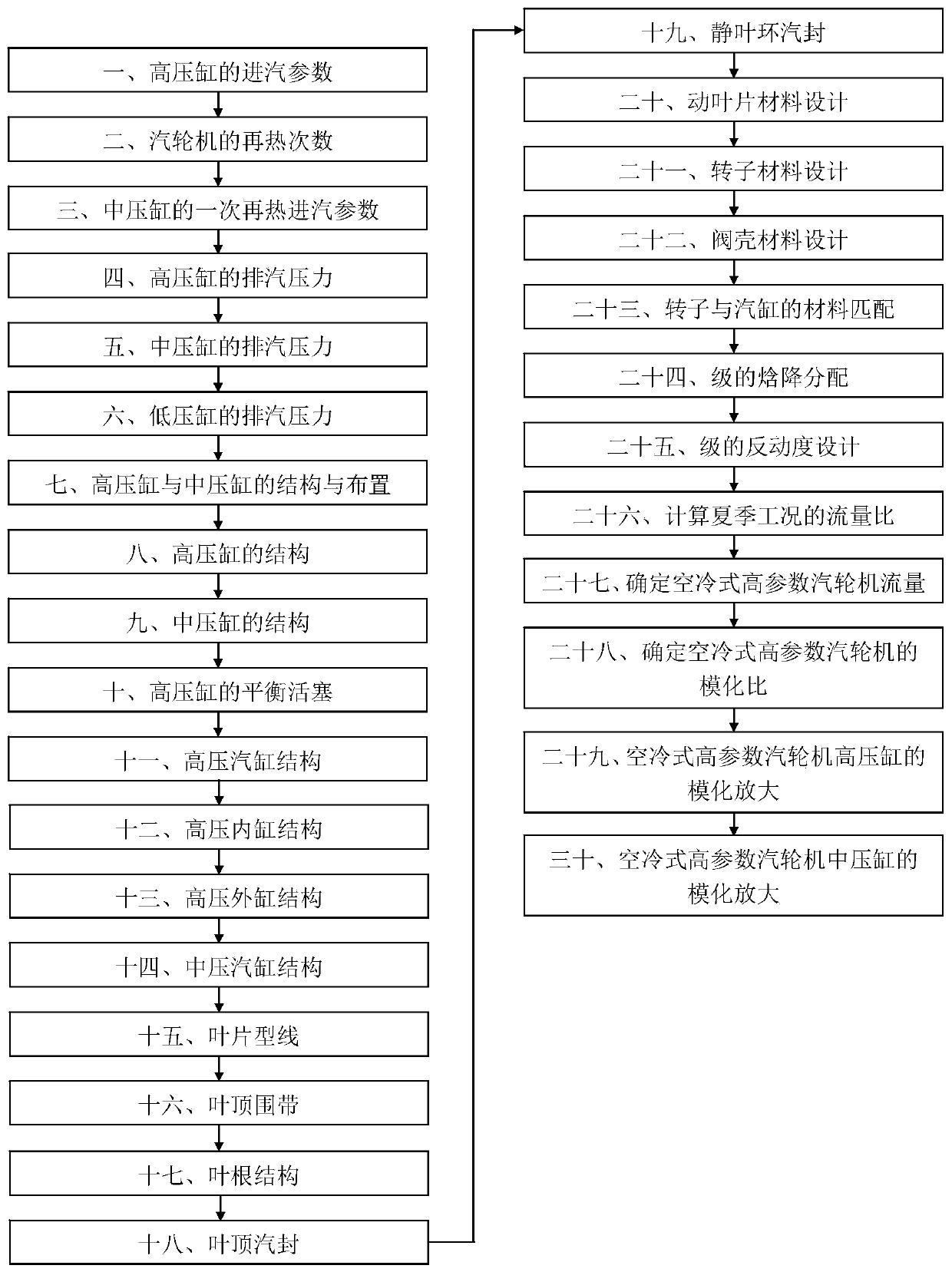

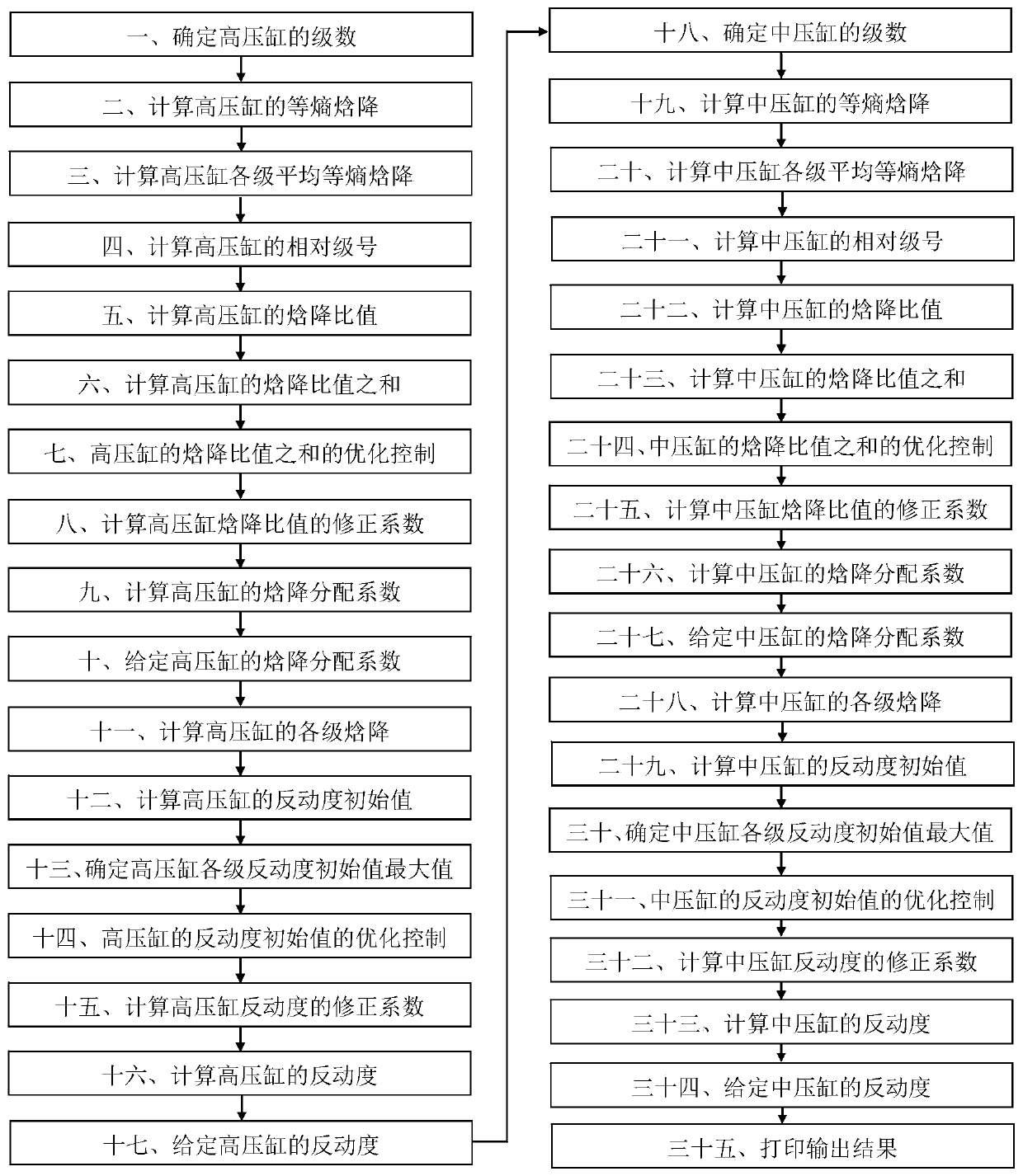

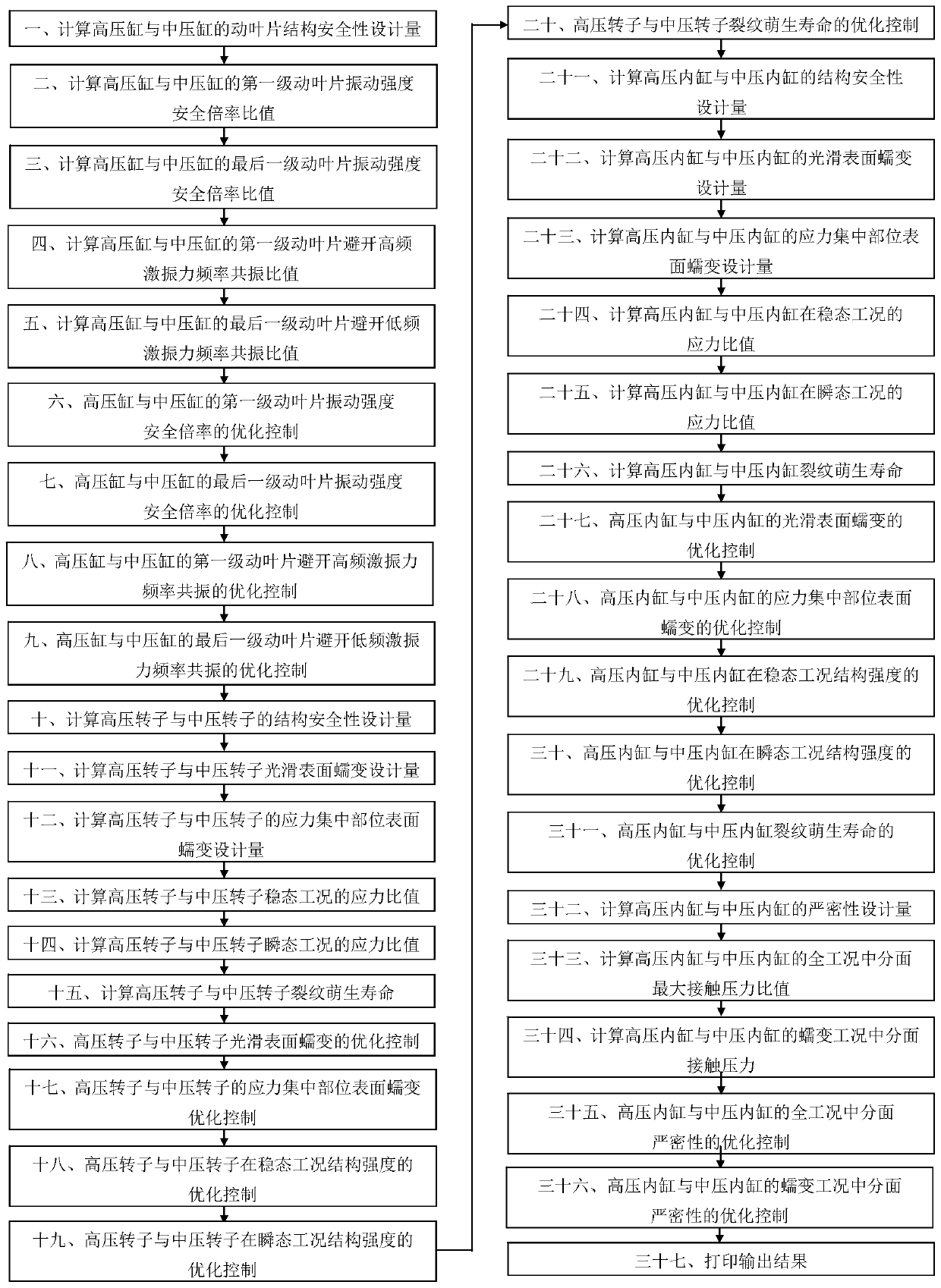

Method used

Image

Examples

Embodiment Construction

[0344] Below in conjunction with specific embodiment, further illustrate the present invention.

[0345] The structure of the high-pressure cylinder 1 of a certain type of air-cooled high-parameter 1100MW steam turbine is as follows: Figure 10 As shown, the high-pressure cylinder 1 includes a high-pressure rotor 2, a balance piston 3, a first-stage moving blade 4 of the high-pressure cylinder, a high-pressure inner cylinder 5, a high-pressure outer cylinder 6, bolts 7, and the last-stage moving blade 8 of the high-pressure cylinder. The structure of the medium pressure cylinder 9 of this type of air-cooled high-parameter 1100MW steam turbine is as follows Figure 11 As shown, the medium pressure cylinder 9 includes components such as a medium pressure rotor 10, a medium pressure inner cylinder 11, a medium pressure outer cylinder 12, a first stage moving blade 13 of the medium pressure cylinder, and a last stage moving blade 14 of the medium pressure cylinder.

[0346] Desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com