Integrated end cover for polypropylene film capacitor

A polypropylene film and capacitor technology, used in film/thick film capacitors, fixed capacitor terminals, laminated capacitors, etc., can solve the hidden dangers of polypropylene film capacitor reliability, inability to meet capacitor performance requirements, labor costs and raw materials Cost increase and other issues, to achieve the effect of saving raw materials, easy welding, and ample internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

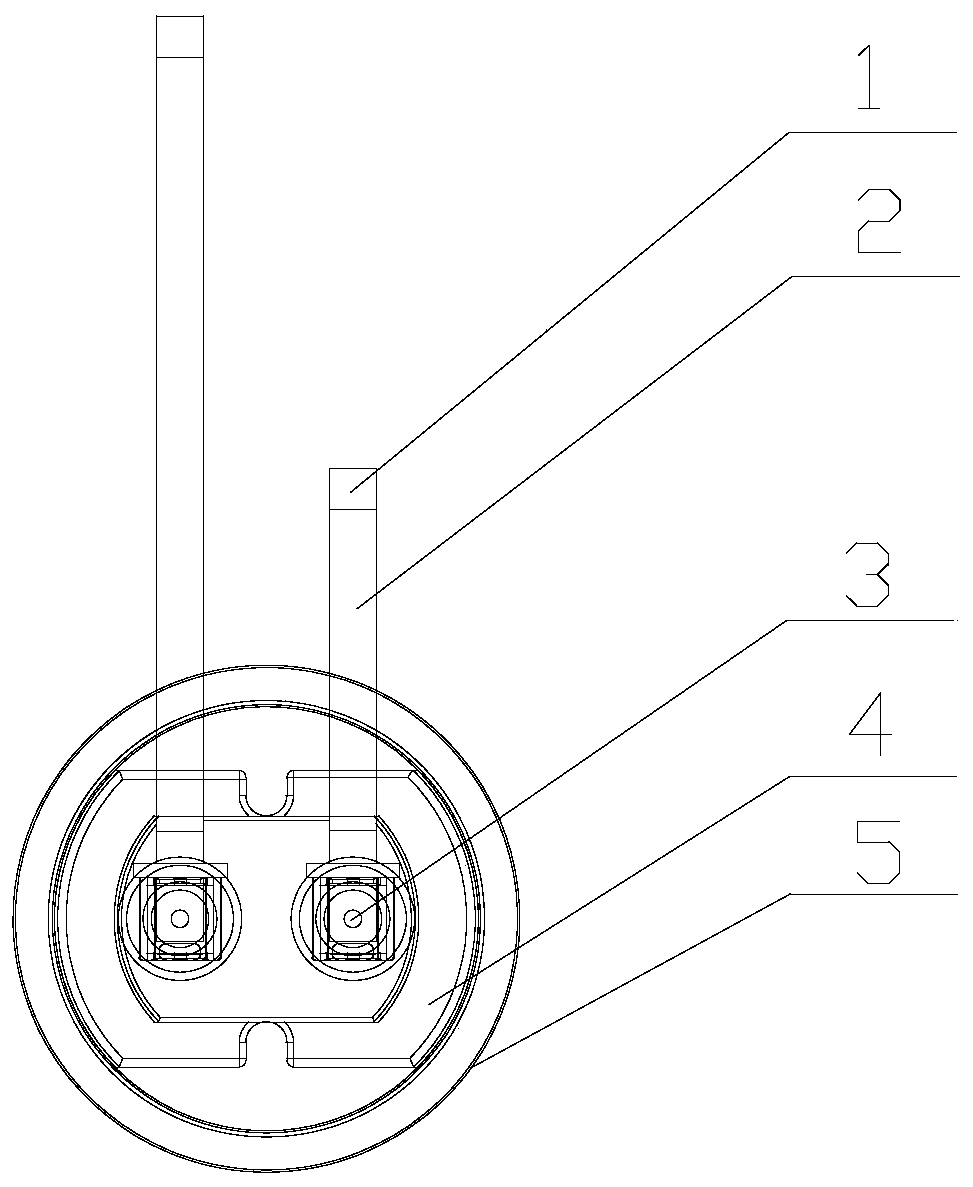

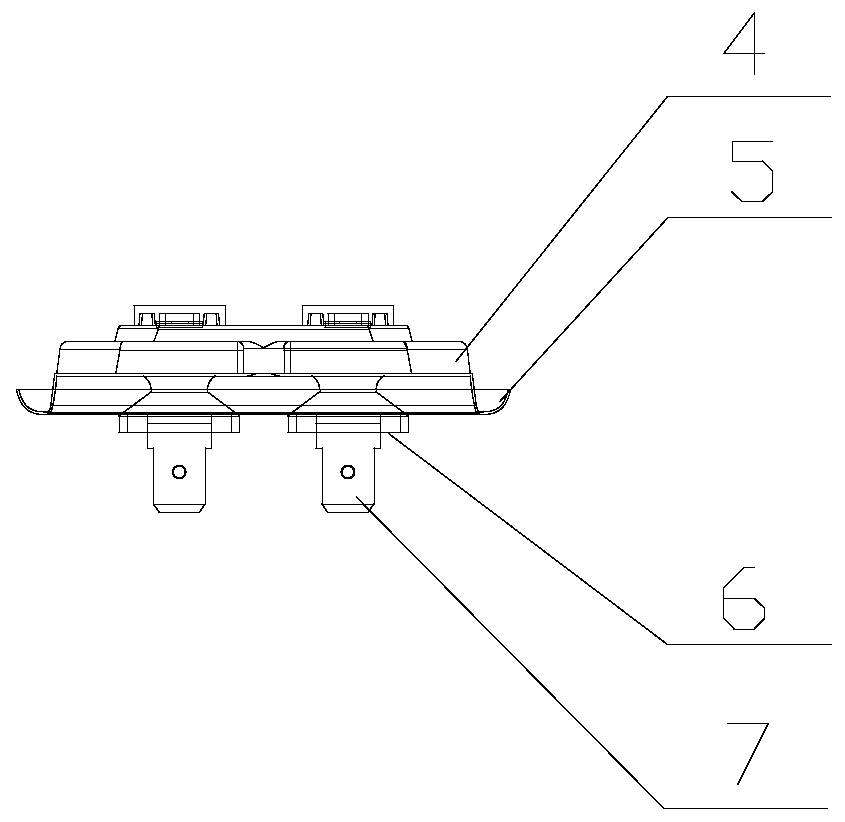

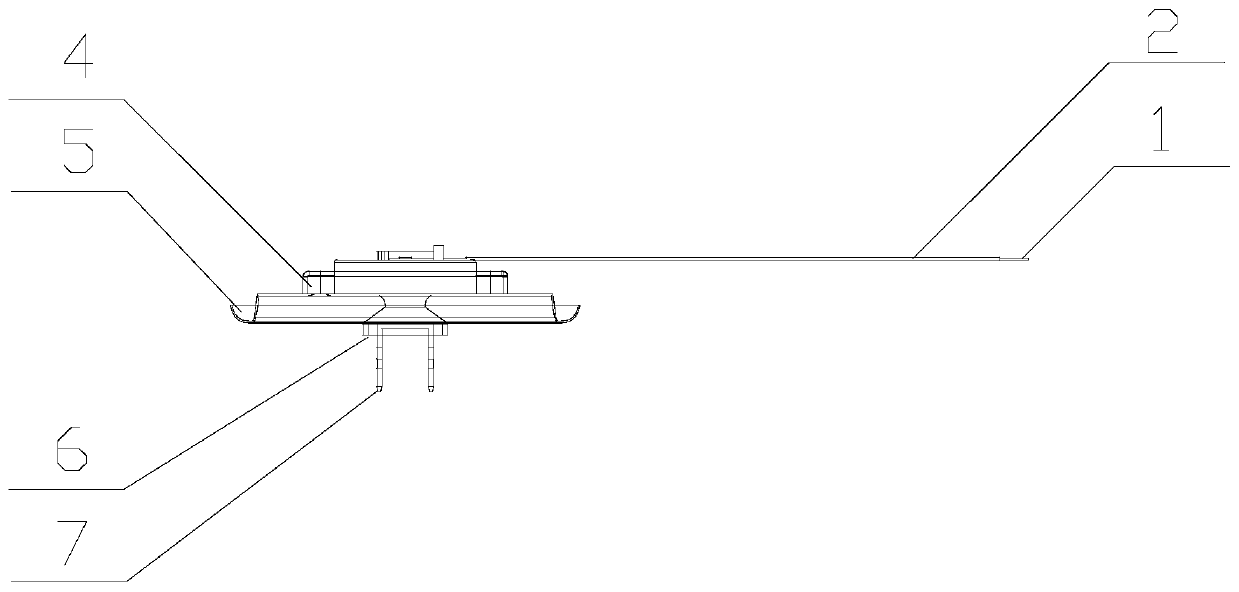

[0024] Such as Figure 1-Figure 3 as shown,

[0025] The invention relates to an end cap for a polypropylene film capacitor, in particular an integrated end cap that saves material, is easy to weld, has high production efficiency, high toughness, high heat dissipation, and high temperature resistance. It consists of copper foil lead wire 1, copper foil lead wire insulation 2, rivet 3, explosion-proof block 4, cover plate 5, insulating bowl 6 and lead end 7 and other parts.

[0026] Wherein, the lead-out 7 and the rivet 3 are integrally formed by stamping respectively, the rivet 3 is arranged at the bottom of the lead-out 7, and the lead-out 7 is installed in the center hole of the insulating bowl 6 through the rivet 3 at the bottom, and then installed on the cover plate 5 correspondingly punched Hole, copper foil lead wire 1 is fixed by inserting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com