Chip-level package multi-face light-emitting LED and packaging method thereof, and backlight module

A chip-level packaging, multi-faceted light-emitting technology, applied in electric light sources, lighting devices, light source fixing and other directions, can solve the problems of high cost, poor effect, adding optical lenses, etc., to achieve cost reduction, large light-emitting angle, and eliminating the need for mounting The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

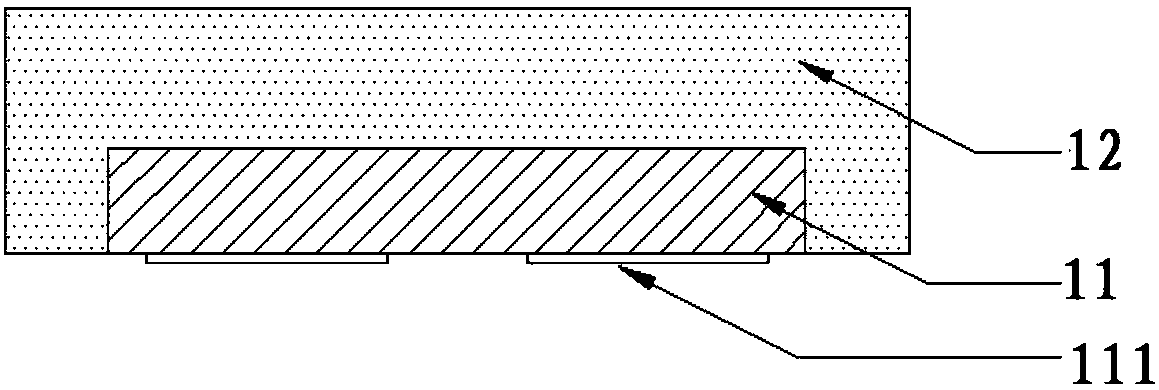

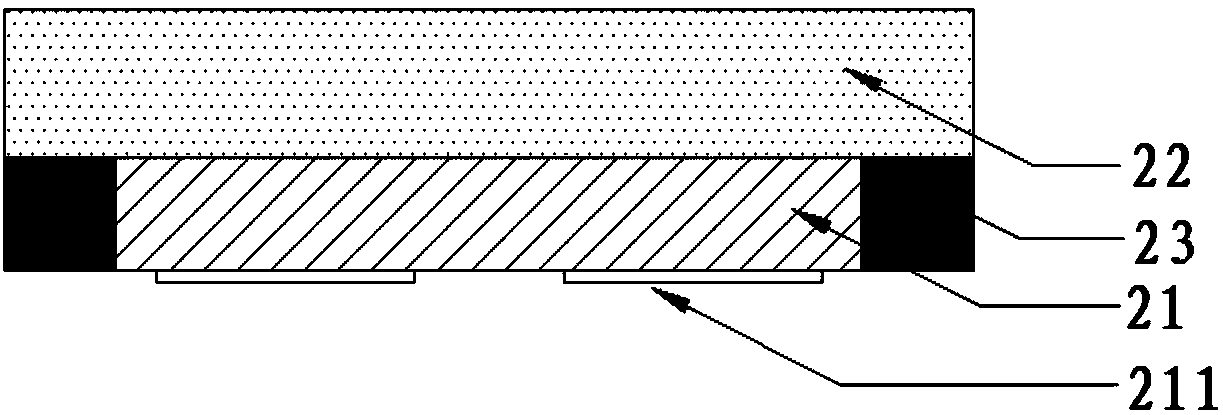

Embodiment 1

[0049] In order to solve the problem that an optical lens needs to be added to the existing CSP LED application, the cost is high, and the effect is poor, this embodiment provides a new packaging method for a multi-faceted light-emitting LED. The LED obtained by this packaging method does not need to add an optical lens when used. The cost is low and the effect is good.

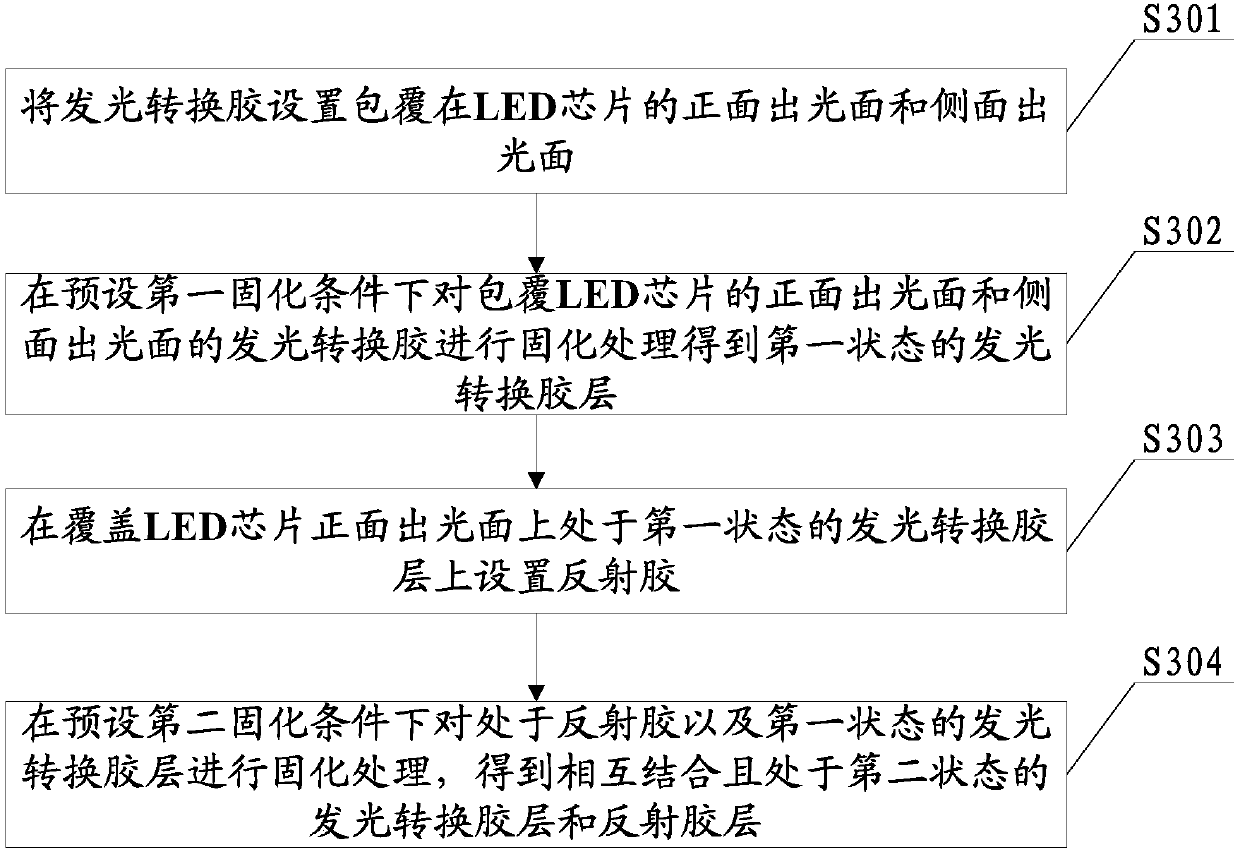

[0050] see image 3 As shown, the multi-faceted light-emitting LED packaging method provided in this embodiment includes:

[0051] S301: Covering the front light-emitting surface and the side light-emitting surface of the LED chip with a light-emitting conversion glue.

[0052] A general LED chip has four sides, and each side is a light-emitting surface, and the top surface is a front surface, which is also a light-emitting surface. Therefore, a general LED chip has a side light emitting surface and a front light emitting surface. The current LEDs are mainly used on the front light-emitting surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com